Multifunctional off-line cleaning device for reverse osmosis membrane

A technology for cleaning devices and reverse osmosis membranes, applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problem of inability to operate reverse osmosis membranes on-site and provide rationalization advice, can not completely solve the problems of membrane pollution, desalination rate, Reduced flow rate and other issues, to achieve the effect of saving drug switching time, avoiding waste, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

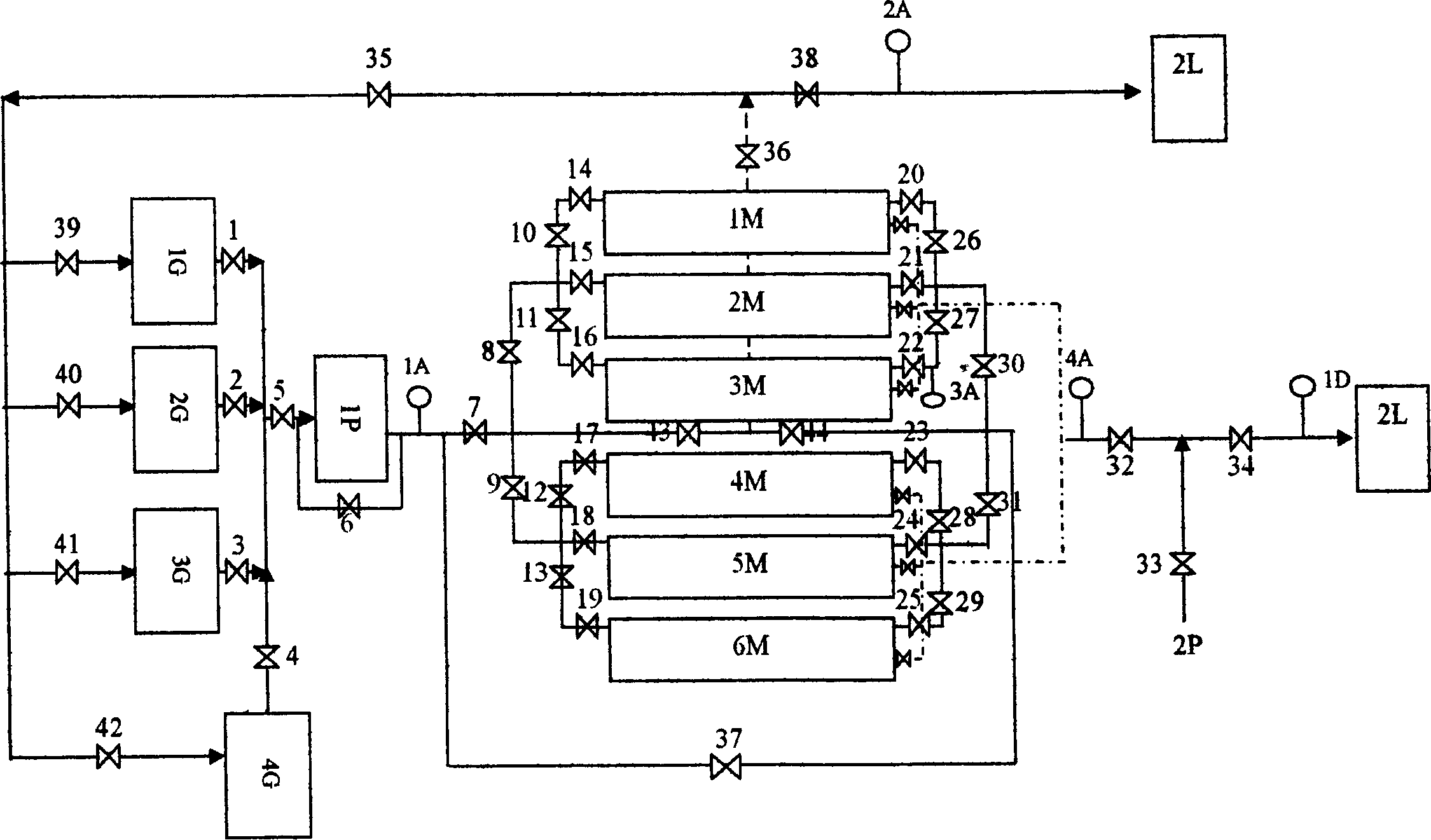

Embodiment 1

[0023] Two reverse osmosis membrane containers are connected in parallel, and each reverse osmosis container is cleaned and flushed independently. Two kinds of cleaning agents are added to the two cleaning tanks of G1 and G2 respectively, and each chemical solution is controlled by valves to perform cycle cleaning operation separately. After the high-pressure pump is controlled by the valve to perform single-branch membrane operation and forward and reverse cycle cleaning, the flow rate of the cleaning liquid entering the membrane element is controlled through the return valve, and the cleaning liquid passes through the reverse osmosis membrane element and returns to the cleaning tank through the valve to continue the cycle cleaning. Rinse from the clean water tank G4 at low pressure, close the circulation valve and open the discharge valve, discharge the flushing liquid directly, flush until the conductance returns to the lowest value, conduct a water production test, measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com