Safety high-efficient continuous enclosed type cell culture and virus production-inactivation system

A cell culture and closed technology, applied in the system field of bioengineering technology, can solve the problems of unfavorable large-scale, continuous, safe production of virus vaccines, non-closed, etc., and achieve the effect of increasing virus production and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

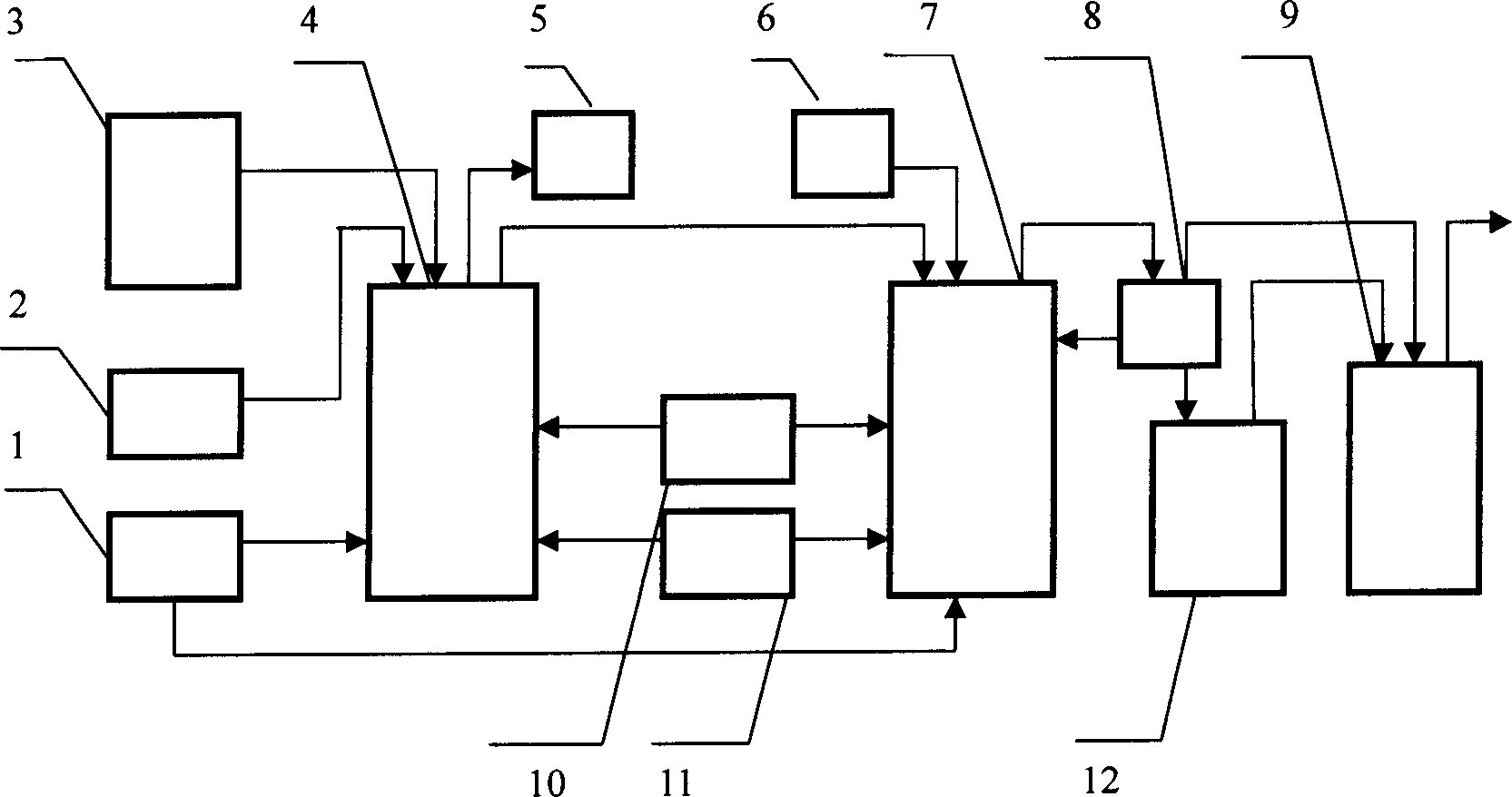

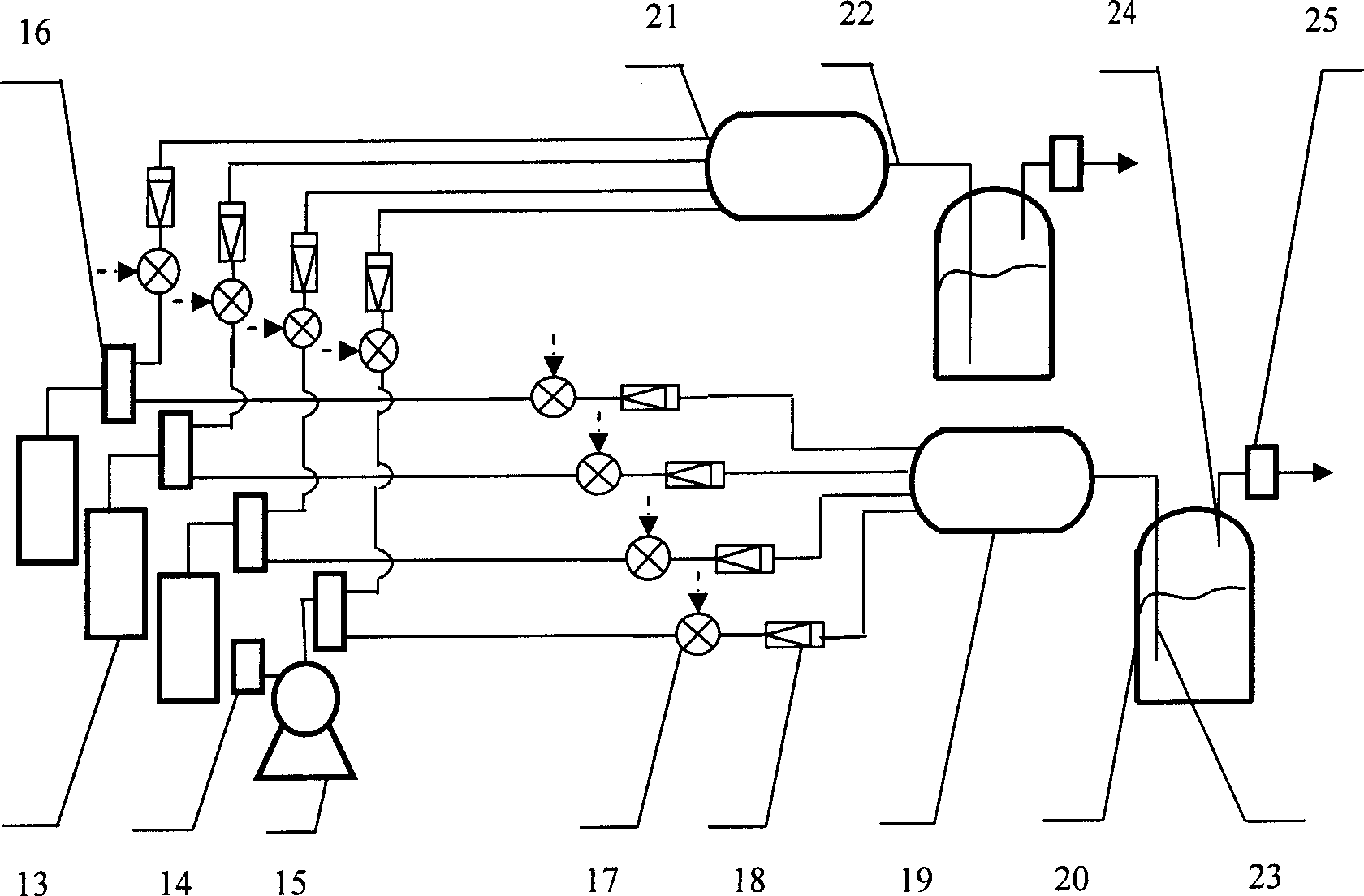

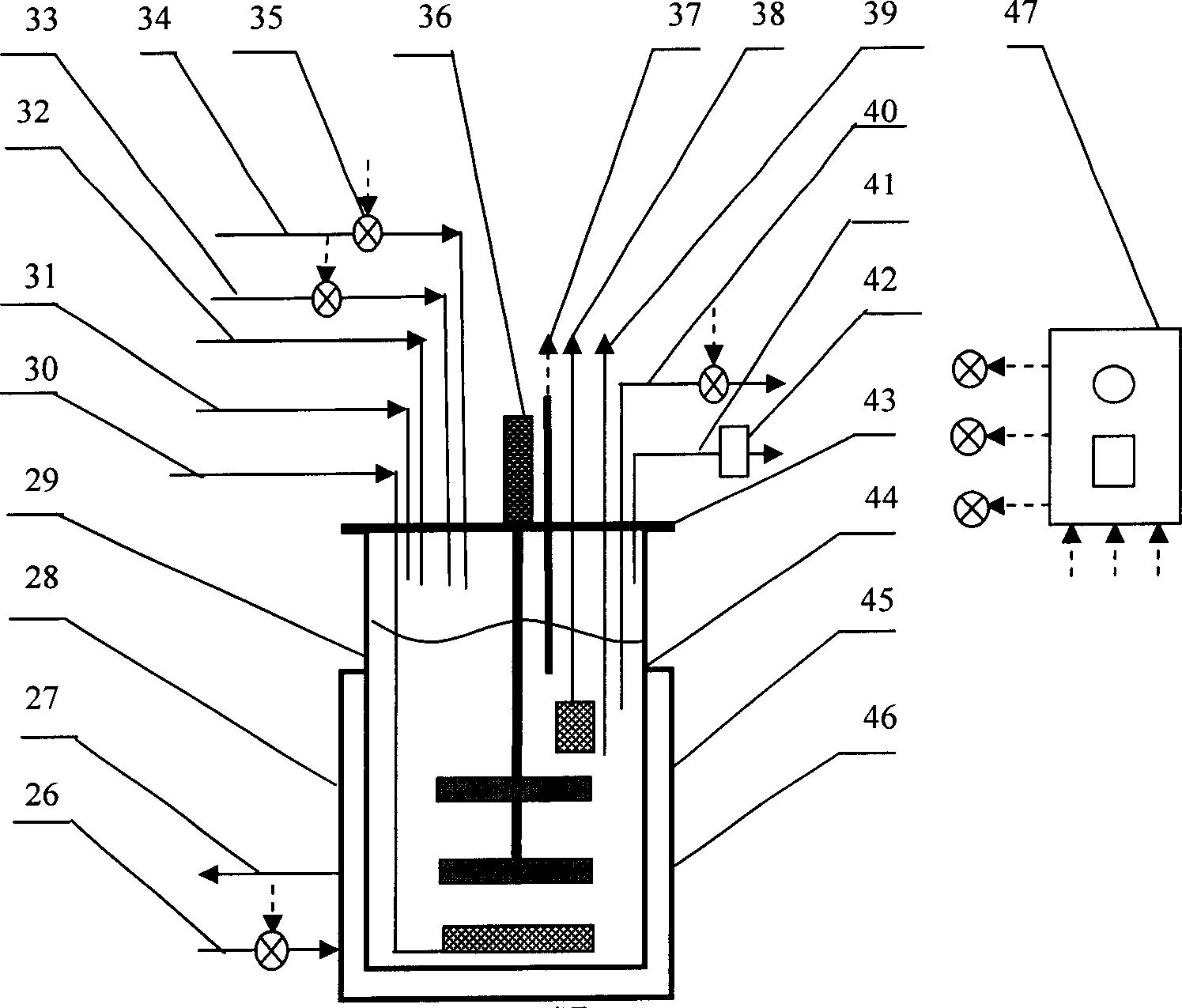

[0030] Such as figure 1As shown, the present invention includes: gas supply unit 1, steam generator 2, cell growth medium supply device 3, cell expansion unit 4, primary perfusion collection device 5, basal medium supply device 6, virus proliferation unit 7, cell / Carrier separation device 8, virus collection device 9, heat source supply device 10, acid / lye supply device 11, obsolete carrier collection device 12. The connection method is as follows: the gas supply unit 1 is divided into two routes, one of the outlet ports is connected to the inlet port of the cell expansion unit 4 to meet the gas requirements for cell expansion, and the other route is connected to the inlet port of the virus multiplication unit 7 to meet the requirements of the virus proliferation unit 7. Gas requirements for proliferation; the outlet port of the steam generator 2 is connected to the inlet port of the cell expansion unit 4 for in-situ sterilization of the entire system; the outlet port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com