Roller type air intake direct injection engine

A technology of engine and roller, applied in the direction of engine components, engine control, machine/engine, etc., can solve the problems of large opening resistance, complex structure, and poor exhaust, so as to achieve fast exhaust operation speed and reduce exhaust resistance and mechanical wear, and prevent the exhaust valve from being burned out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

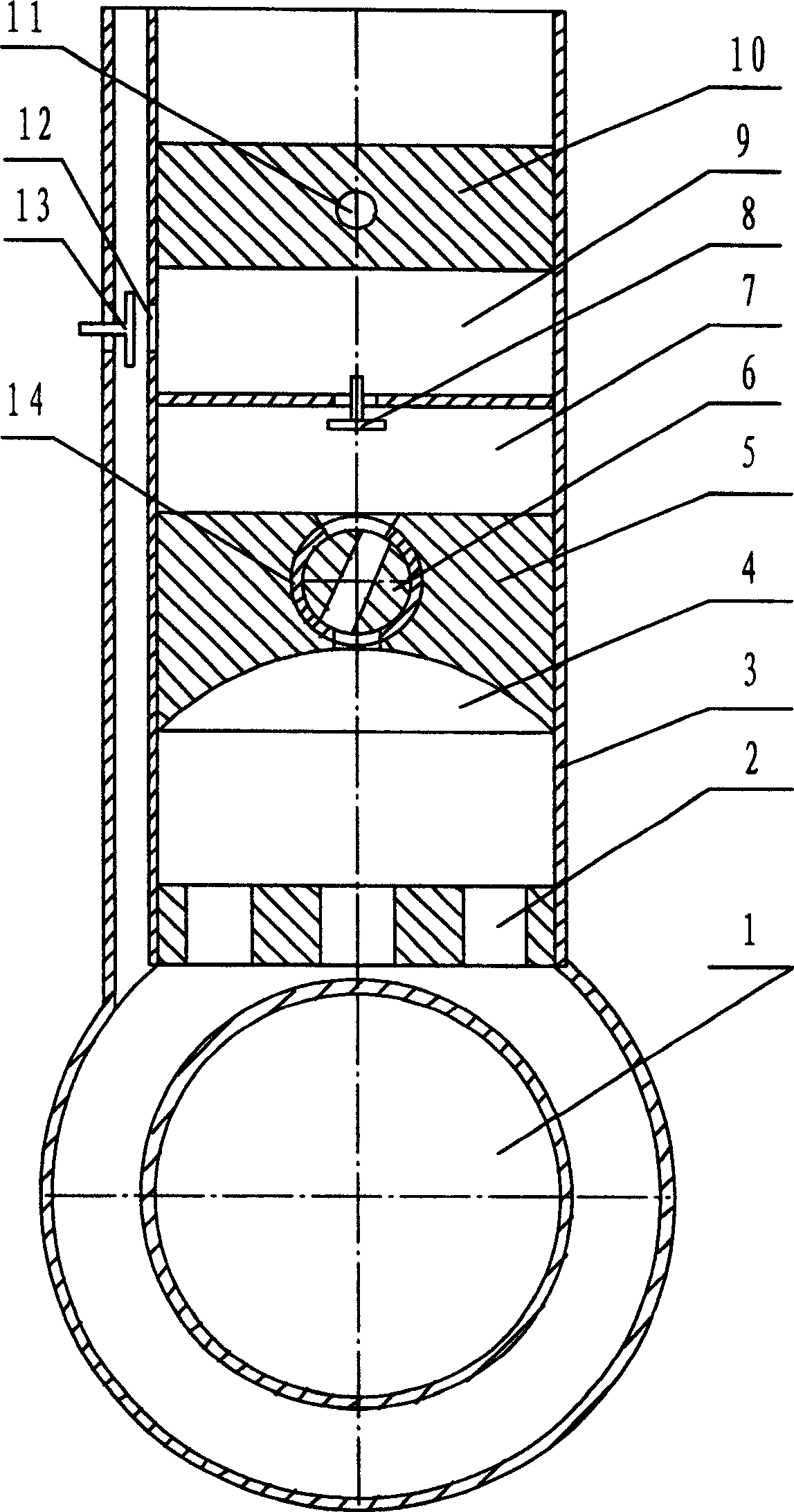

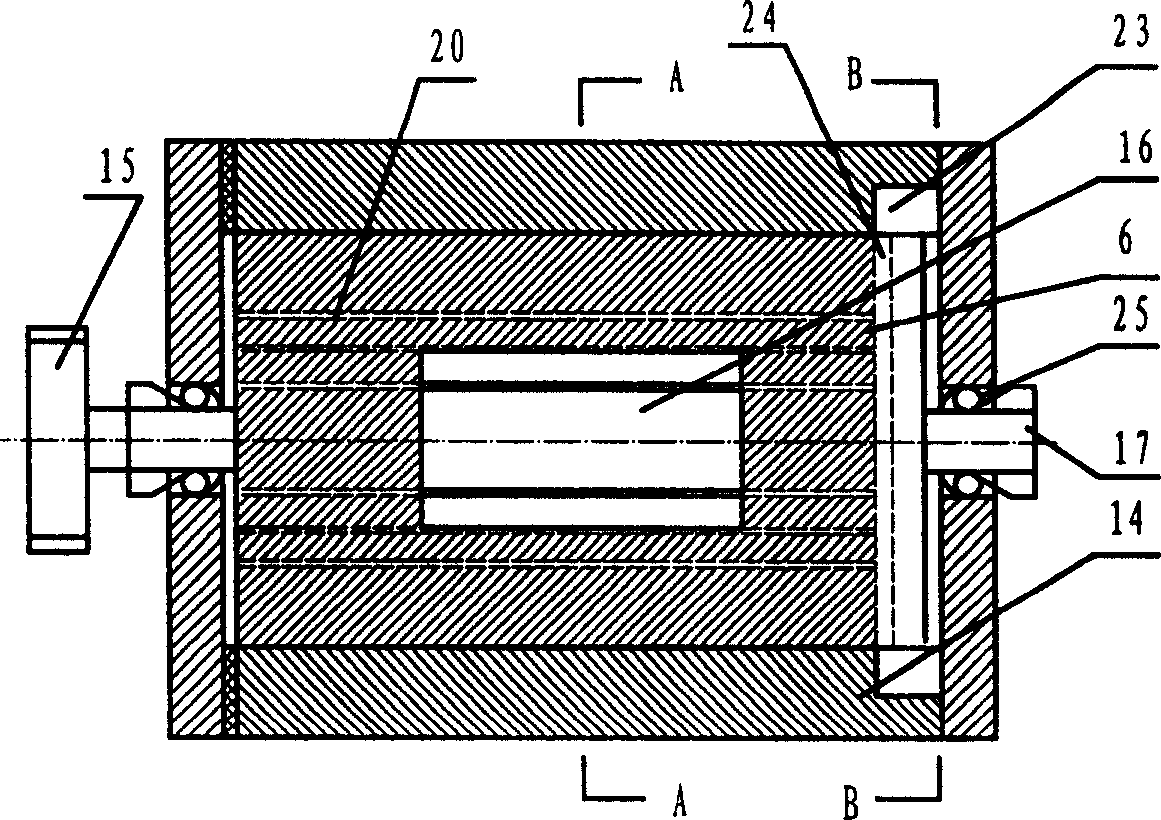

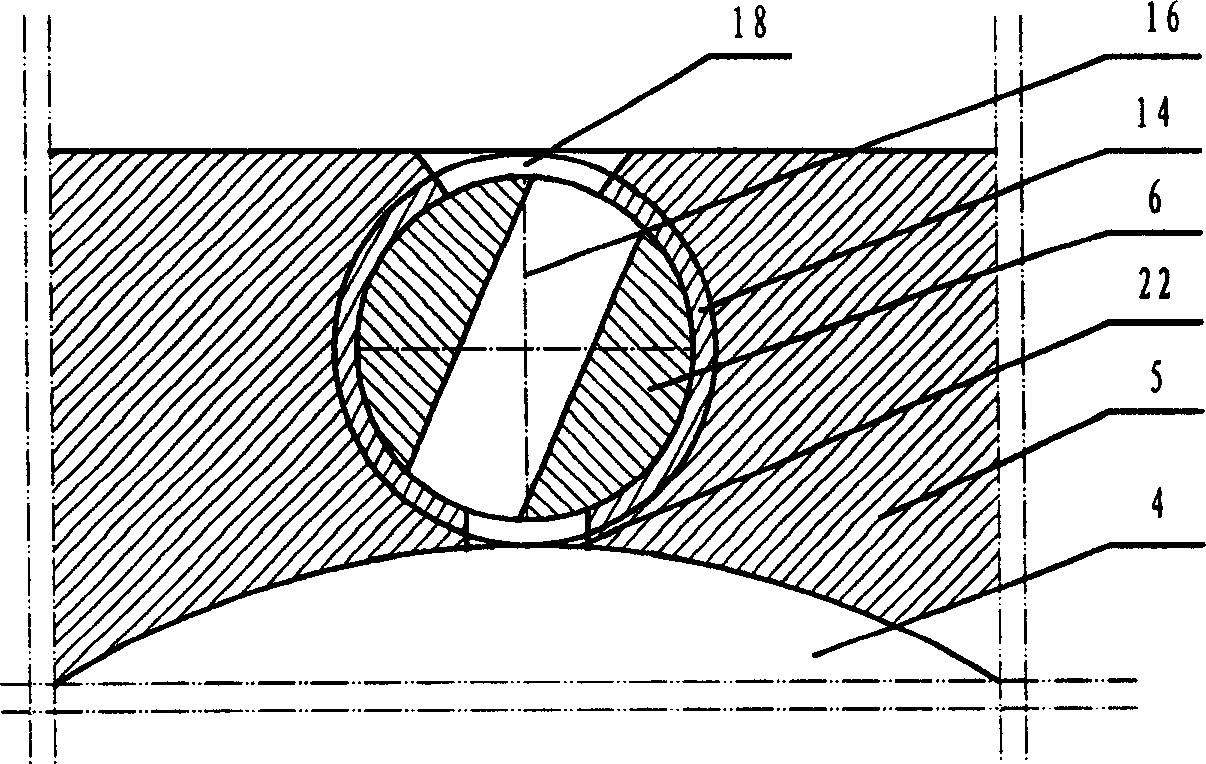

[0025] Embodiment 1, the present invention comprises the cylinder 3 that establishes vent hole 2 and the crankshaft 1 that cooperates with it and piston, establishes the cylinder head 5 of combustion chamber 4 in cylinder 3, is provided with fuel injection nozzle on cylinder head 5, combustion chamber 4 The air intake adopts roller type valve, and described roller type valve is made up of cylinder head 5 and valve roller 6, and valve intake hole 18 is arranged in cylinder head 5, and valve intake hole 18 is provided with valve intake The hole 18 is vertical to the valve roller installation hole, and the valve roller 6 is matched in the valve roller installation hole. The transmission shaft 17 that roller 6 is connected is fixedly connected with transmission wheel 15. When the engine piston goes down to the exhaust hole 2, the exhaust is exhausted, and the roller intake chamber 16 of the valve roller 6 moves to the position where the scavenging hole 22 communicates, so that the...

Embodiment 2

[0026] Embodiment 2: The present invention can also be provided with the oil groove 20 that cooperates with the valve roller 6 on the inner wall of the valve roller installation hole in the valve inlet hole 18, the oil groove 20 communicates with the oil inlet hole, and realizes lubrication and sealing through the oil groove 20 . refer to Figure 1 to Figure 4 , all the other are with embodiment 1.

Embodiment 3

[0027] Embodiment 3: In the present invention, the valve roller sleeve 14 can also be fixedly connected to the outer wall of the valve roller 6 , and the valve roller sleeve 14 is provided with an air inlet hole matching with the valve air inlet hole 18 and the scavenging hole 22 . An oil groove 20 matching the valve roller 6 may also be provided on the inner wall of the valve roller sleeve 14, and the oil groove 20 communicates with the oil inlet hole. refer to Figure 1 to Figure 4 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com