Integrated optical metrology and lithographic process system for dynamic critical dimension control

A lithography process and process technology, which is applied in the direction of optics, photolithography process exposure devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of general products without structure and inconvenience, increase process capacity and yield, and reduce process stoppage The number of times, the effect of improving production capacity and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

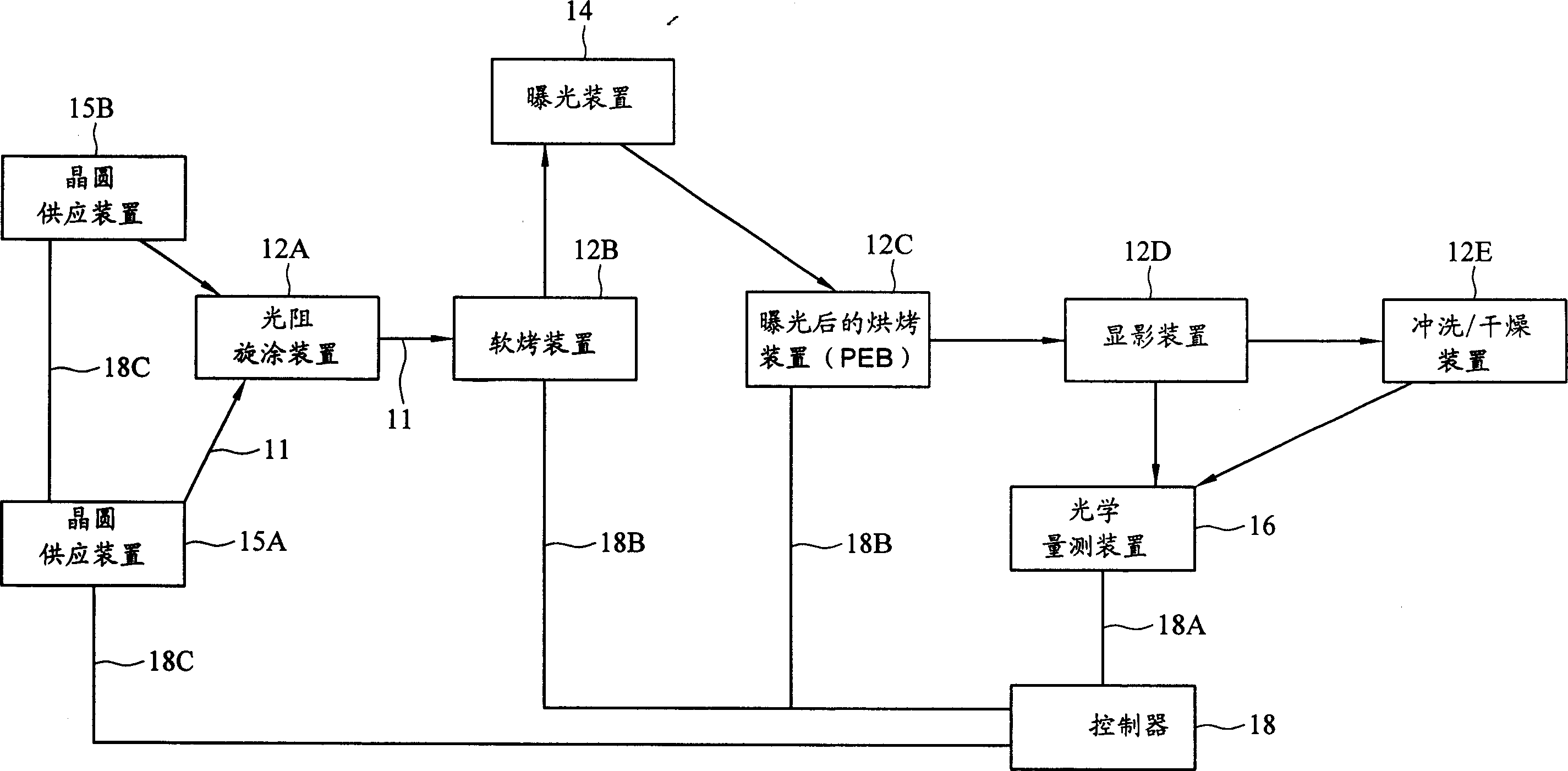

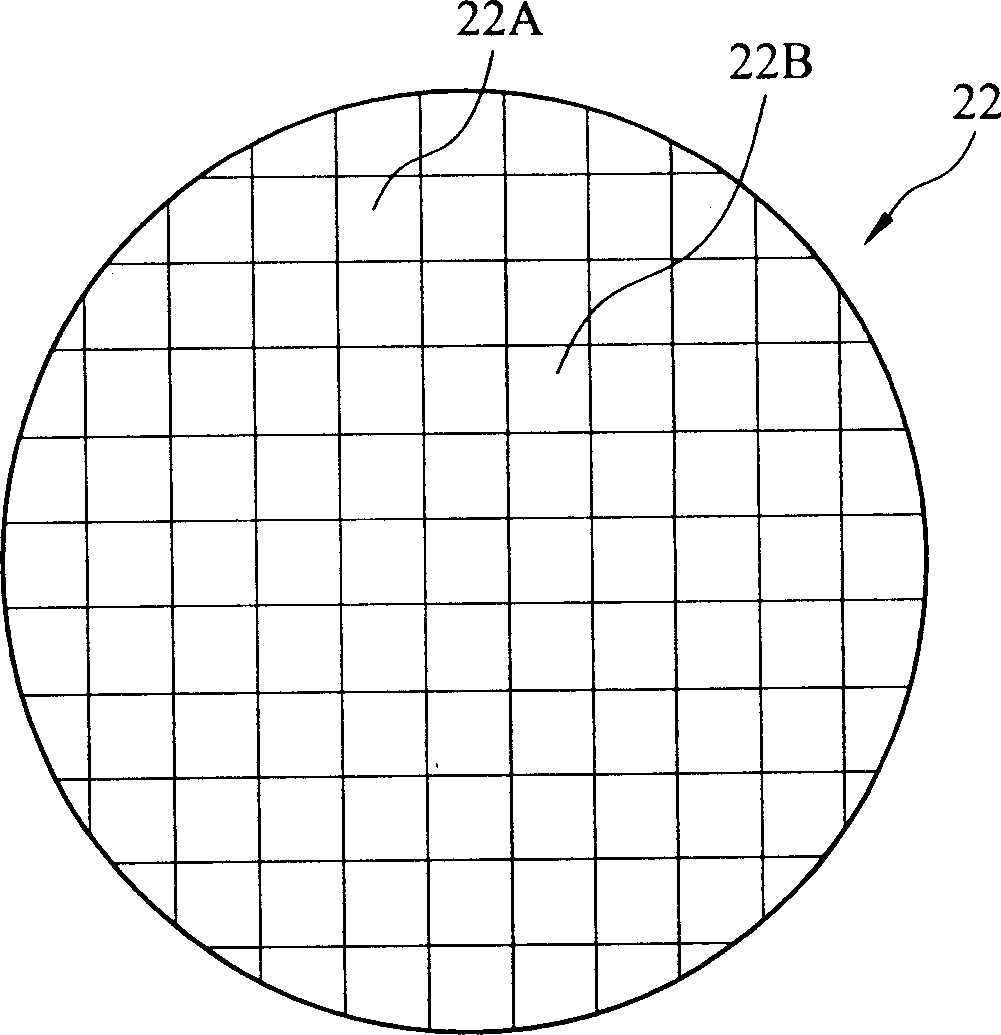

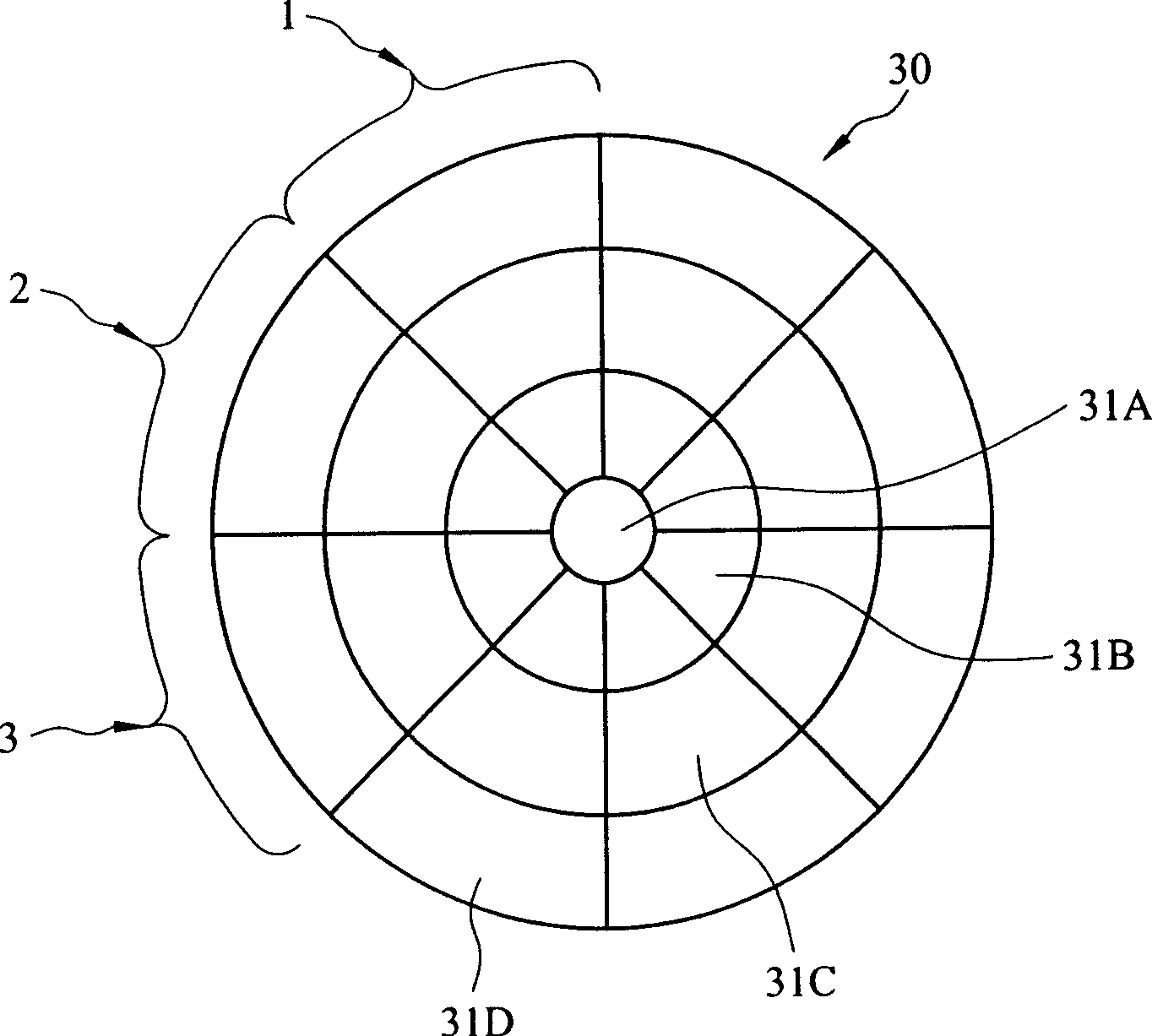

[0045] In order to further illustrate the technical means and effects of the present invention to achieve the intended purpose of the invention, the integrated optical measurement and lithography proposed according to the present invention for dynamically controlling the feature size will be described below in conjunction with the accompanying drawings and preferred embodiments. The specific implementation, structure, steps, features and functions of the manufacturing process system are described in detail below.

[0046] Although the implementation of the present invention is illustrated by improving the accuracy and uniformity of the feature size of the patterned photoresist layer in an integrated circuit as an example, the present invention is also applicable to the application field of Micro-engineered Machine, and is also applicable to A photoresist pattern whose feature dimension line width is less than 0.25 microns is used to perform subsequent dry etching process using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com