Tungsten rod and quartz direct sealed type ultra-high voltage capillary mercury lamp

A direct-sealing, ultra-high-voltage technology, which is applied to the components of gas discharge lamps, etc., can solve the problems of complex manufacturing process, high cost, and difficulty in adapting to ultra-high-voltage working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

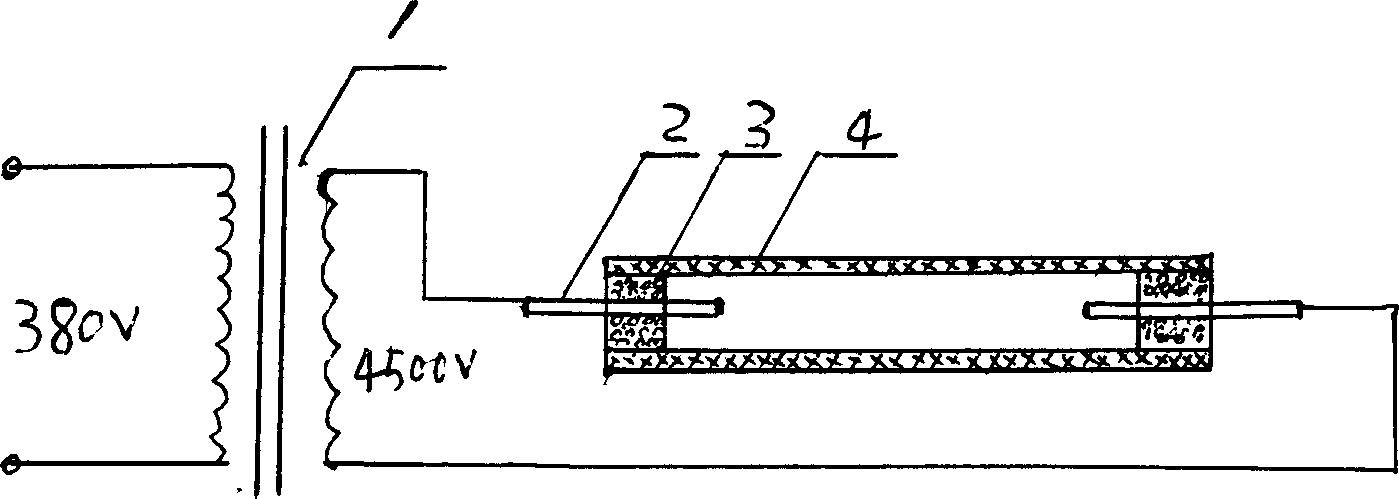

[0008] Quartz glass beads 3 are made by mixing quartz sand, borax, tungsten powder, sodium oxide, aluminum oxide, calcium oxide, barium oxide, etc., stirring evenly, grinding them and sintering them with a hydrogen-oxygen flame at high temperature. The tungsten electrode 2 and the quartz capillary 4 are fused together in the high temperature of the hydrogen-oxygen flame. The sealed quartz lamp tube should be connected to the vacuum system according to the process requirements for exhaust, electrode glow, mercury filling, etc. After the exhaust is qualified, it is separated from the vacuum system. Seal the exhaust pipe at last, and the quartz capillary tube has just been made like this, and the capillary tube of making will be connected to the aging test in the 4500 volt transformer 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com