Semiconductor device manufacturing method

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as difficulty in obtaining strength, difficulty in forming slit hole alignment, etc., and achieve reduction in the number of processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

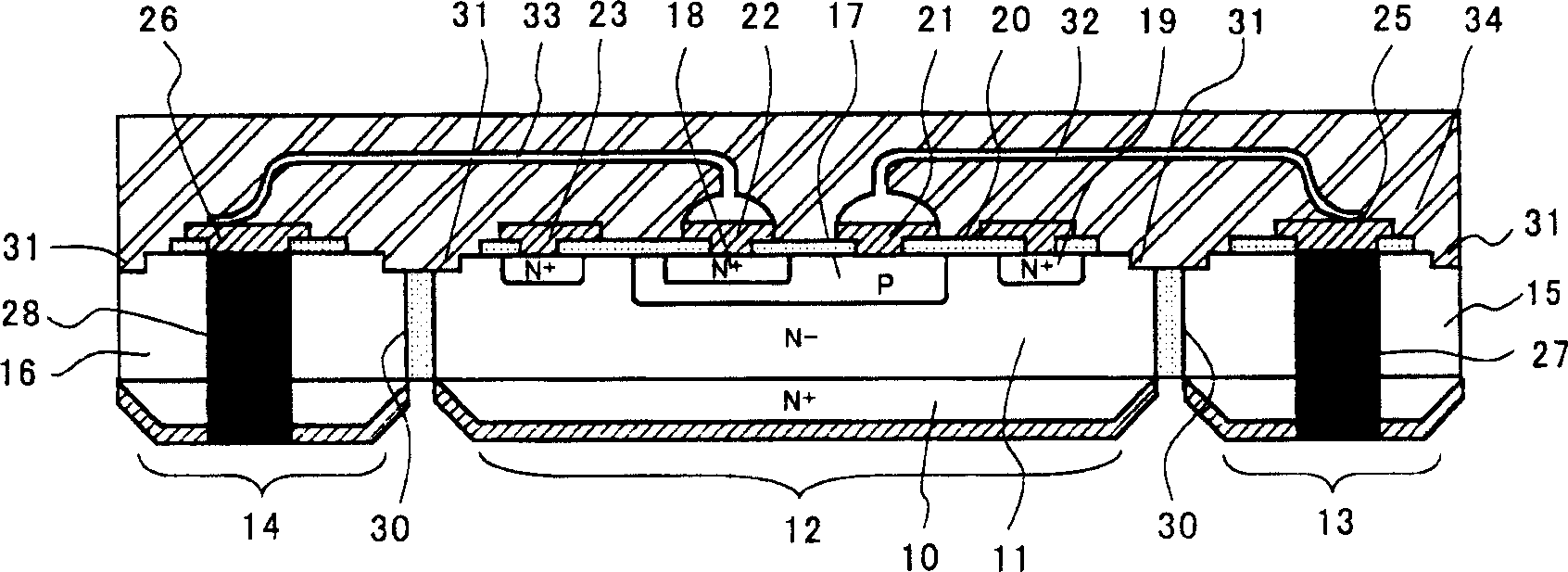

[0050] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings.

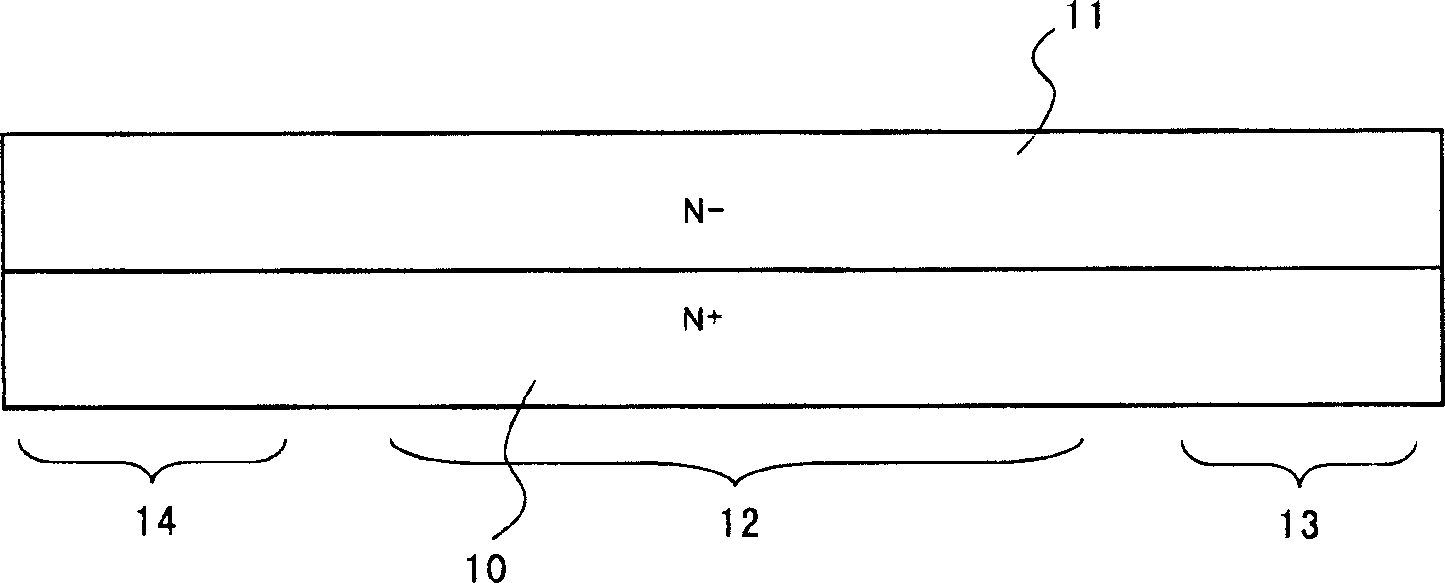

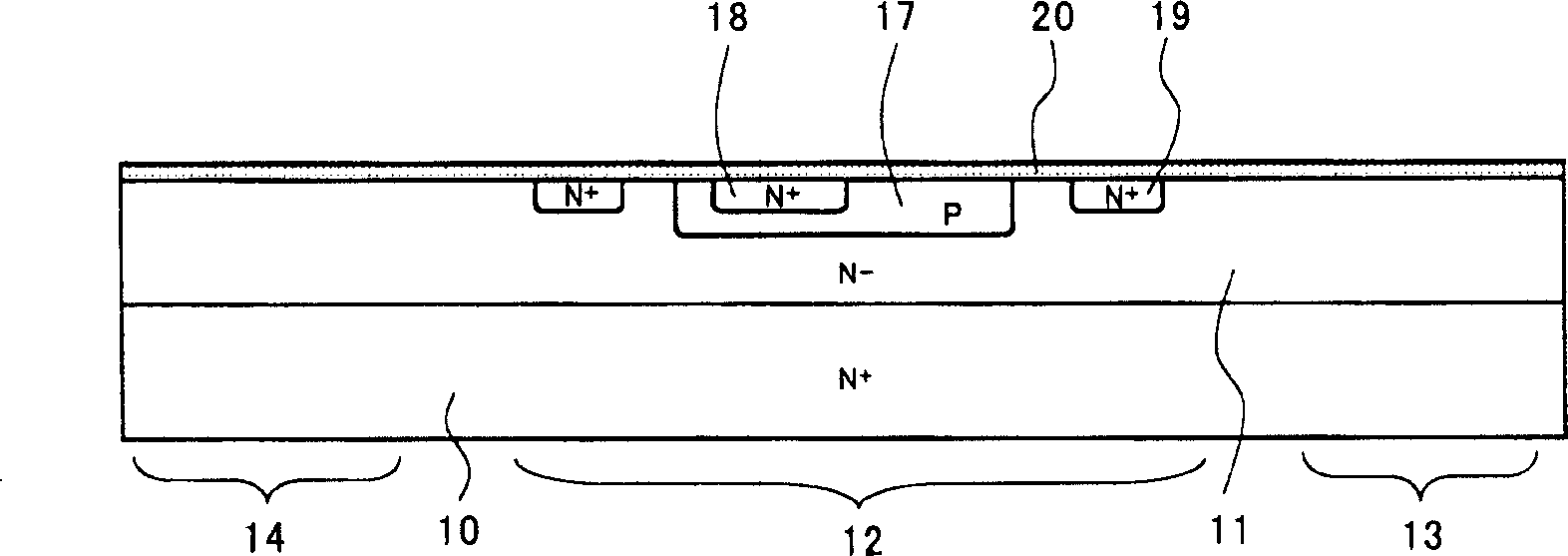

[0051] figure 1 It is a cross-sectional view illustrating a semiconductor device completed by the manufacturing method of the present invention. Figure 2 to Figure 9It is a cross-sectional view illustrating a method of manufacturing a semiconductor device of the best mode for carrying out the present invention, Figure 10 It is a plan view illustrating an arrangement relationship of electrodes of a semiconductor device of the best form for carrying out the present invention.

[0052] Such as figure 1 As shown, the semiconductor device completed by the manufacturing method of the present invention has: a semiconductor substrate, which has a first region and a second region; a plurality of electrodes, which are connected to the circuit element provided in the first region and the circuit element ; an electrode for external connection, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com