Underwater hydraulic impacting shovel

A hydraulic impact and hydraulic cylinder technology, which is applied in the field of impact shovels, can solve the problems of increased friction of the sealing structure, a large impact on impact efficiency, and the sealing cannot meet the requirements, etc., to achieve the effect of increasing impact force, improving efficiency, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

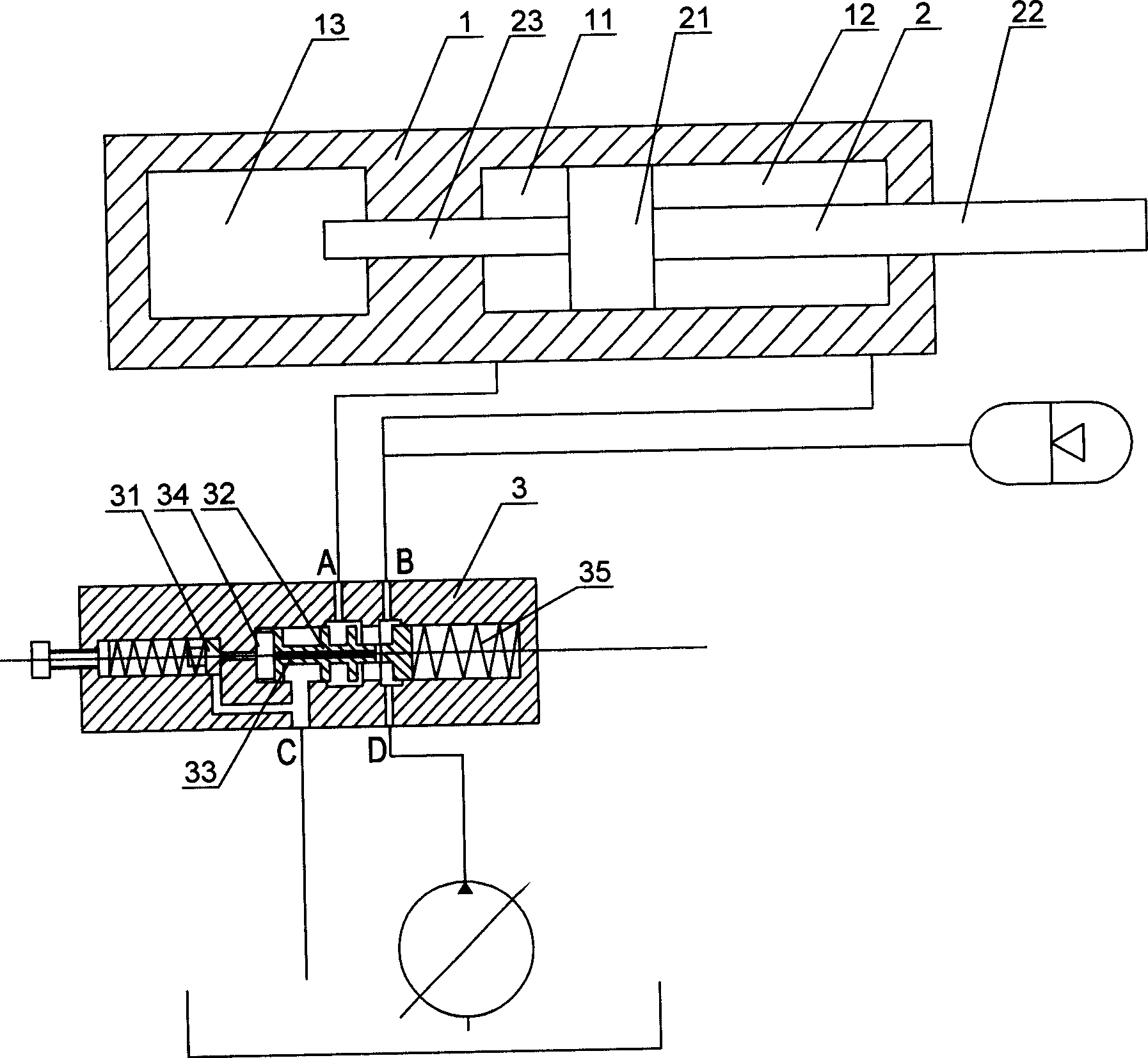

[0029] The invention discloses an underwater hydraulic impact shovel, such as figure 1 Shown is a schematic diagram of its working principle. In the figure, the hydraulic cylinder 1 is divided into a variable pressure chamber 11 and a normal high pressure chamber 12 by the piston 21 of the piston rod 2. In addition, a high pressure nitrogen chamber 13 is arranged at the rear of the hydraulic cylinder, and the piston rod 2 is divided into a front rod 22 and a rear bar 23. In the figure, the oil distributing valve 3 includes four ports A, B, C, and D, and a cone spool 31 and a spool 32 of the oil distributing valve are also arranged inside it. In addition, a through hole is also arranged in the spool 32. 33.

[0030] Such as figure 1 In the state shown, the high-pressure oil from the oil pump enters the oil distribution valve 3 through the D port, and then enters the left chamber 34 of the valve core through the through hole 33 of the valve core. The spring 35 pushes the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com