Wavelength calibration method during optical fiber Bragg grating sensing wavelength demodulation

A technology of optical fiber Bragg and Bragg wavelength, which is applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of increased manufacturing cost, complexity of FBG sensing wavelength demodulation system, and high price, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

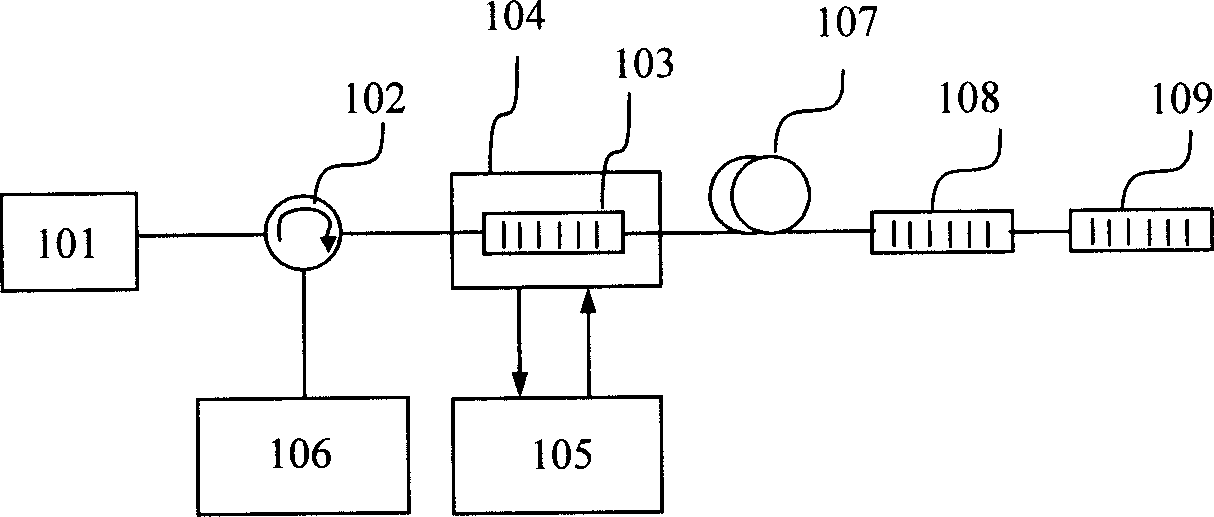

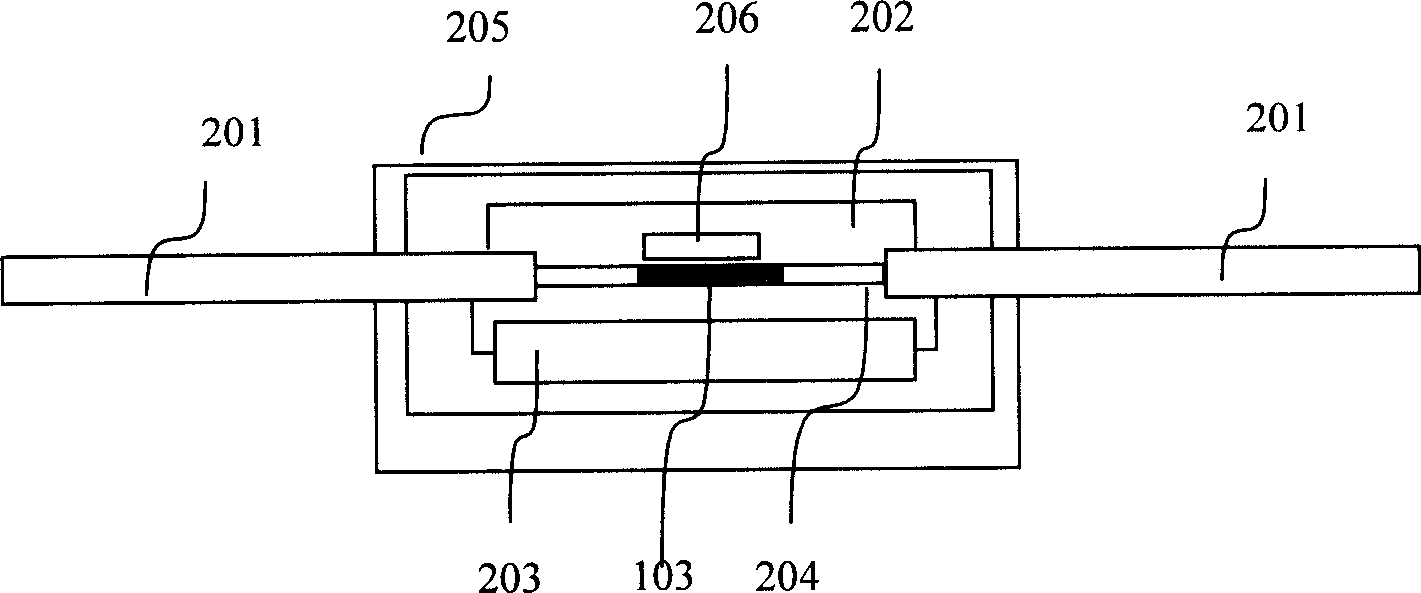

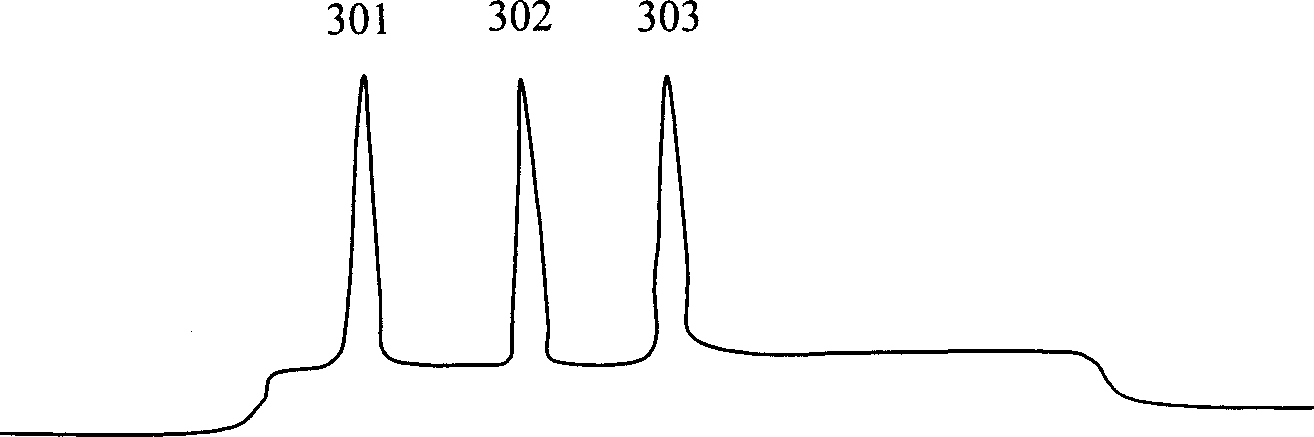

[0015] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. as attached figure 1 As shown, the broad-spectrum light emitted by the broadband light source 101 first passes through the circulator 102 to the wavelength reference device 104, and then passes through the transmission fiber 107 to the fiber Bragg grating sensors 108 and 109 connected in series. The wavelength reference device 104, the fiber Bragg grating sensors 108 and 109 have different Bragg wavelengths and do not overlap each other during the measurement. as attached figure 2 As shown, the wavelength reference device 104 is composed of a fiber grating 103 , a semiconductor refrigerator 203 , a metal plate 204 and a metal casing 205 . The thermistor 206 is installed close to the fiber grating 103 , and is fixed on the surface of the metal plate 204 by epoxy resin 202 . The output signal of the thermistor 206 is connected to the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com