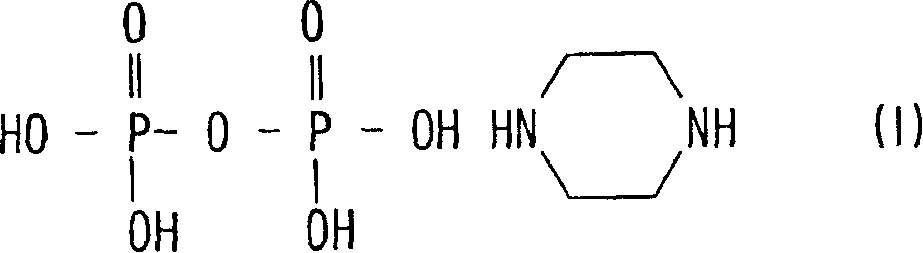

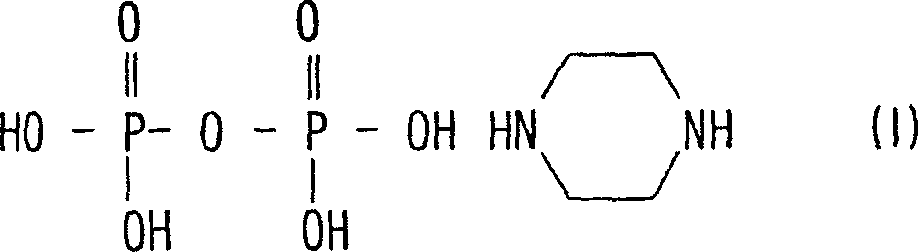

High-purity piperazine pyrophosphate and method for producing same

A technology of piperazine pyrophosphate and piperazine diphosphate, which is applied in the field of high-purity piperazine pyrophosphate and its manufacture, can solve the problem of inability to manufacture piperazine pyrophosphate cheaply, unable to obtain flame retardancy, and poor physical properties of synthetic resins. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

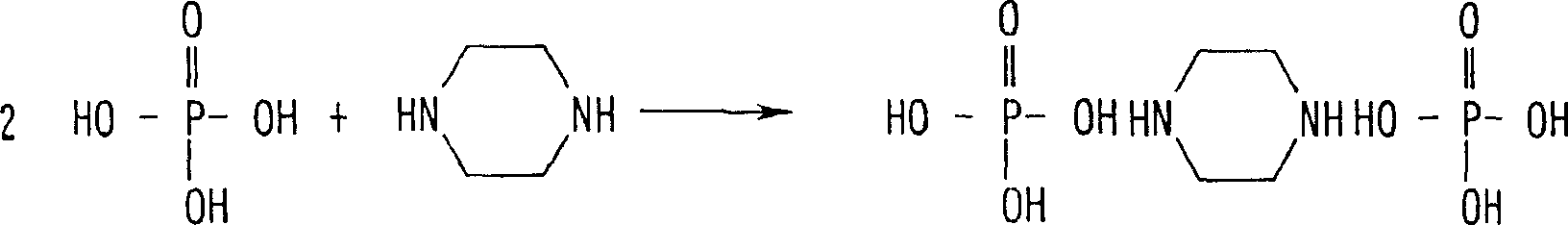

Method used

Image

Examples

Embodiment 1

[0040] Using an extruder (manufactured by Japan Steel Works, TEX44αII-52.5BW), under the condition that the barrel temperature is 230-280°C, the raw material supply speed is 25kg / h, and the screw speed is 60rpm, piperazine diphosphate is heated and mixed to obtain White powder of piperazine pyrophosphate.

Embodiment 2

[0042] Using a Henschel mixer (manufactured by Mitsui Mine, FM150J / T, capacity 150L), under the conditions of heating temperature 190-250°C and rotation speed 704-1000rpm, heat and mix 40 kg of piperazine diphosphate for 1 hour to obtain coke White powder of piperazine phosphate.

Embodiment 3

[0044] Using a Henschel mixer (manufactured by Mitsui Mine, FM150J / T, capacity 150L), at a heating temperature of 170 to 250°C and a rotating speed of 990 to 1590rpm, 5kg of piperazine diphosphate and 100g of 75% by weight of Phosphoric acid is heated and mixed to obtain a white powder of piperazine pyrophosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com