Chemical deposition process of preparing composite nanometer mesoporous silver halide/alumina material

A technology of aluminum oxide nanometer and chemical deposition method, which is applied in the direction of silver halide, nanotechnology, nanotechnology, etc., and can solve the problems of high cost and high requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

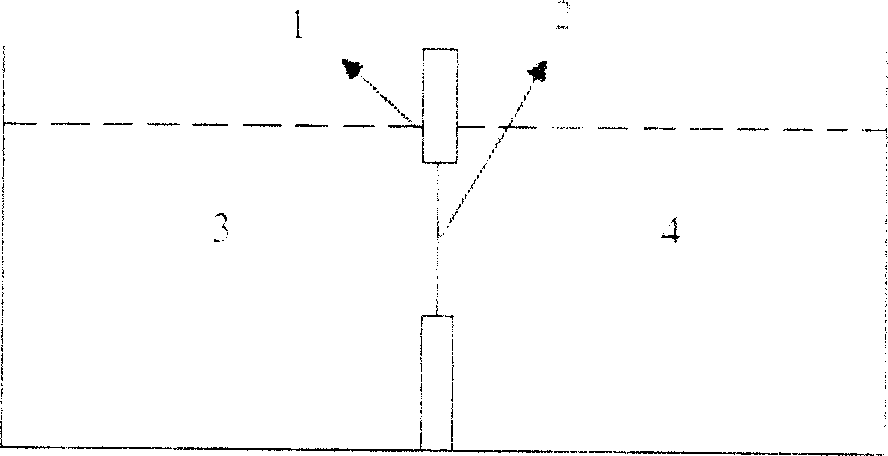

[0033] Soak the AAO template in deionized water and sonicate for 10 minutes. After the ultrasonic treatment, the AAO template was placed in an aqueous gelatin solution with a concentration of 0.8% by mass, and soaked for 30 minutes, wherein the temperature of the aqueous gelatin solution was 70°C. Take the AAO template out of the gelatin aqueous solution, rinse both surfaces with 95°C deionized water to remove the gelatin on the template surface, immediately place it in an aqueous solution of alum with a concentration of 1% by mass, soak for 5 minutes, and the temperature of the aqueous alum solution is 0 ℃. Soak the above-treated AAO template in a concentration of 0.5mol.L -1 In the potassium iodide solution, the soaking time is 10 minutes. After removing the AAO template from the potassium iodide solution, the surface was quickly rinsed with deionized water, and then fixed on a surface such as figure 1 In the reaction apparatus shown.

[0034] The addition of the reactio...

Embodiment 2

[0037] Soak the AAO template in deionized water and sonicate for 30 min. After the ultrasonic treatment, the AAO template was placed in an aqueous gelatin solution with a concentration of 5% by mass, and soaked for 50 minutes, wherein the temperature of the aqueous gelatin solution was 90°C. Take the AAO template out of the gelatin solution, rinse both surfaces with 100°C deionized water to remove the gelatin on the template surface, and immediately place it in a 6% formaldehyde solution by mass percentage for 10 minutes, wherein the temperature of the formaldehyde solution is 10°C. Soak the above-treated AAO template in a concentration of 0.3mol.L -1 In the ammonium iodide solution, the soaking time is 15 minutes. After removing the AAO template from the ammonium iodide solution, the surface was quickly rinsed with deionized water, and then fixed on a surface such as figure 1 In the reaction apparatus shown.

[0038] The addition of the reaction solution was started. Add...

Embodiment 3

[0041] Soak the AAO template in deionized water and sonicate for 5 min. After the ultrasonic treatment, the AAO template was placed in an aqueous gelatin solution with a concentration of 1% by mass, and soaked for 50 minutes, wherein the temperature of the aqueous gelatin solution was 80°C. Take the AAO template out of the gelatin aqueous solution, rinse both surfaces with 100°C deionized water to remove the gelatin on the template surface, and immediately place it in an aqueous solution of alum with a concentration of 1.5% by mass, and soak for 20 minutes, wherein the temperature of the aqueous alum solution is 0°C. Soak the above-treated AAO template in a concentration of 1.5mol.L -1 In the ammonium bromide solution, the soaking time is 15 minutes. After removing the AAO template from the ammonium bromide solution, the surface was quickly rinsed with deionized water, and then fixed on a surface such as figure 1 In the reaction apparatus shown.

[0042] The addition of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com