Mesoporous material preparation method using fly ash

A technology of mesoporous materials and fly ash, which is applied in the field of waste recycling, can solve the problems of restricting large-scale production and increasing costs, and achieve the effects of saving costs, eliminating harm to the environment, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) First, mix fly ash and NaOH (mass ratio 1:1) and melt at 500°C for 1 hour, then cool to obtain the mixture;

[0025] (2) Then, add distilled water to the mixture to dissolve, filter and take the supernatant for use, wherein the supernatant is aluminosilicate solution;

[0026] (3) Dissolve the surfactant P123 in distilled water, add 2M HCl until the pH is 0.9, and the molar ratio of each substance in the mixed precursor solution is 1Si:0.016P123:5.4HCl:200H 2 O, fully stirred at 35~40°C; after aging in an oven at 95°C for 24 hours, filter, wash, and dry;

[0027] (4) Finally, the dried material was calcined at 550°C for 5 hours, the heating rate was 1°C / min, and the powdered mesoporous material was obtained after cooling.

Embodiment 2

[0029] (1) First, mix fly ash and NaOH (mass ratio 1:1.2) and melt at 550°C for 1.5h, then cool to obtain the mixture;

[0030] (2) Then, add distilled water to the mixture to dissolve, filter and take the supernatant for use, wherein the supernatant is aluminosilicate solution;

[0031] (3) Dissolve the surfactant P123 in distilled water, add 2M HCl until the pH is 0.6, and the molar ratio of each substance in the mixed precursor solution is 1Si:0.016P123:17.3HCl:200H 2 O, fully stirred at 35~40°C; after aging in an oven at 95°C for 24 hours, filter, wash, and dry;

[0032] (4) Finally, the dried material was calcined at 550°C for 5 hours, the heating rate was 1°C / min, and the powdered mesoporous material was obtained after cooling.

Embodiment 3

[0034] (1) First, mix fly ash and NaOH (mass ratio 1:1.3) and melt at 600°C for 2 hours, cool to obtain the mixture; (2) Then, add distilled water to the mixture to dissolve, filter to get the supernatant The liquid is ready for use, wherein the supernatant is an aluminosilicate solution;

[0035] (3) Dissolve the surfactant P123 in distilled water, add 2M HCl until the pH is 0.3, and the molar ratio of each substance in the mixed precursor solution is 1Si:0.016P123:24.5HCl:200H 2 O, fully stirred at 35~40°C; after aging in an oven at 95°C for 24 hours, filter, wash, and dry;

[0036] (4) Finally, the dried material was calcined at 550°C for 5 hours, the heating rate was 1°C / min, and the powdered mesoporous material was obtained after cooling.

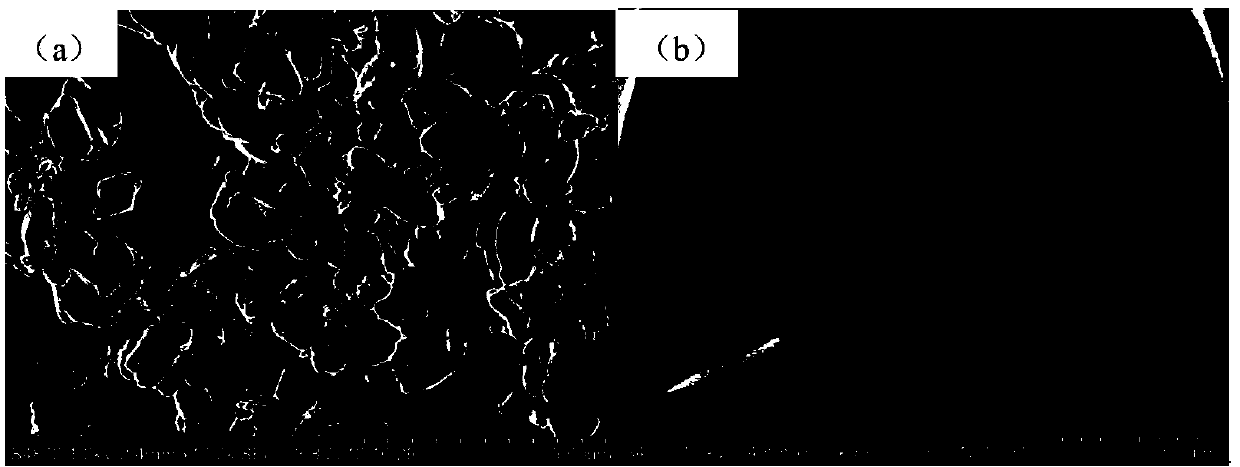

[0037] figure 1 It is the SEM photo of SBA-15-CFA in Example 3, where picture (a) is a low magnification (10K) SEM picture, and picture b is a high magnification (80K) SEM picture. figure 2 It is a TEM photo of the adsorption mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com