Method for controlling formula in silicon chip etching technology

A control method and process technology, applied in the direction of electrical program control, non-electric variable control, control/regulation system, etc., can solve the problems of complicated control of etching equipment process parameters, time-consuming parameter setting methods, inconvenient adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Those of ordinary skill in the relevant technical field can also make various changes and modifications without departing from the spirit and scope of the present invention. Therefore All equivalent technical solutions also belong to the category of the present invention, and the scope of patent protection of the present invention should be defined by each claim.

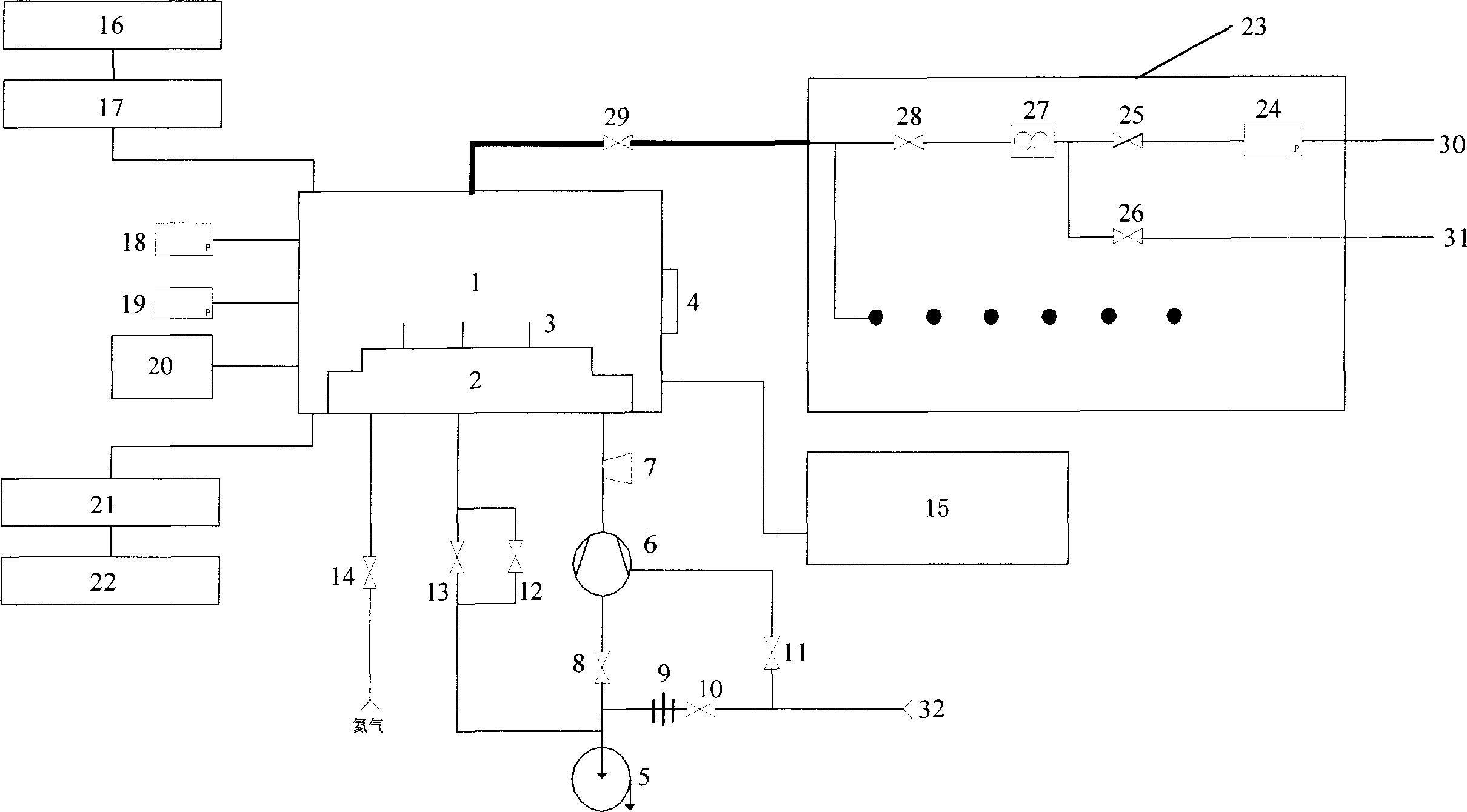

[0026] The silicon wafer etching process system realized by the method of the present invention can be divided into the following seven subsystems according to the purpose: vacuum subsystem, gas delivery subsystem, lower electrode subsystem (E_Chuck subsystem), chamber subsystem (chamber subsystem), RF subsystem (radio frequency subsystem), temperature control subsystem (temperature control subsystem), end point subsystem (endpoint subsystem). The structure of the system is as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap