Electrical connection structure for superconducting element

A technology of electrical connection structure and connection structure, which is applied in the usage of superconductor elements, connection contact materials, cable accessories of low temperature cables, etc., can solve problems such as expensive manufacturing constraints, difficult connection structure field maintenance, and gas composition changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

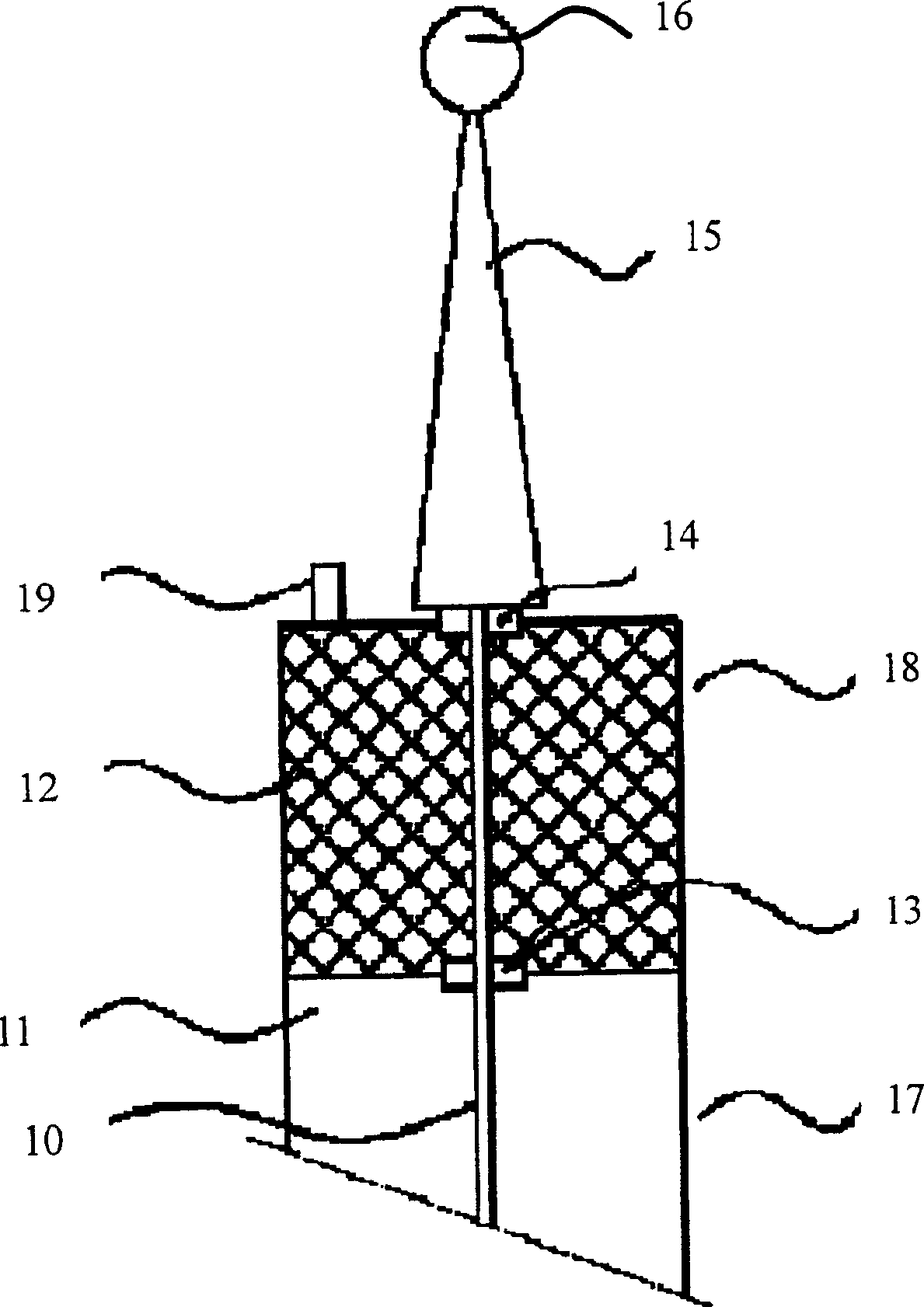

[0012] exist figure 1 In , the structure for connection to a superconductor cable (not shown) comprises an electrical bushing 10 connected to the superconductor element through the bottom end in an enclosure 11 located at cryogenic temperature. The intermediate housing 12 adjacent to the low temperature housing 11 is filled with a solid material of low thermal conductivity. The material is preferably in the form of a foam, such as polyurethane foam or cellular glass foam, such as is commercially available under the trademark Foamglas. The electrical bushing 10 passes through the bottom wall of the intermediate housing 11 via an airtight fastening flange 13 and through the top wall via an airtight fastening flange 14 . The electrical bushing 10 extends through the intermediate housing 12 into an enclosure 15 at ambient temperature, which terminates at electrical connection means 16 for connecting the bushing, and thereby the superconductor element, up to suitable devices and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com