Water cutoff structure of covered wire

A covered wire and water-stop technology, which is applied in the direction of cable joints, bases/shells, and connection insulation, can solve the problems of poor water-stop function, prolong welding time, increase costs, etc., achieve high water-stop function, and eliminate welding dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

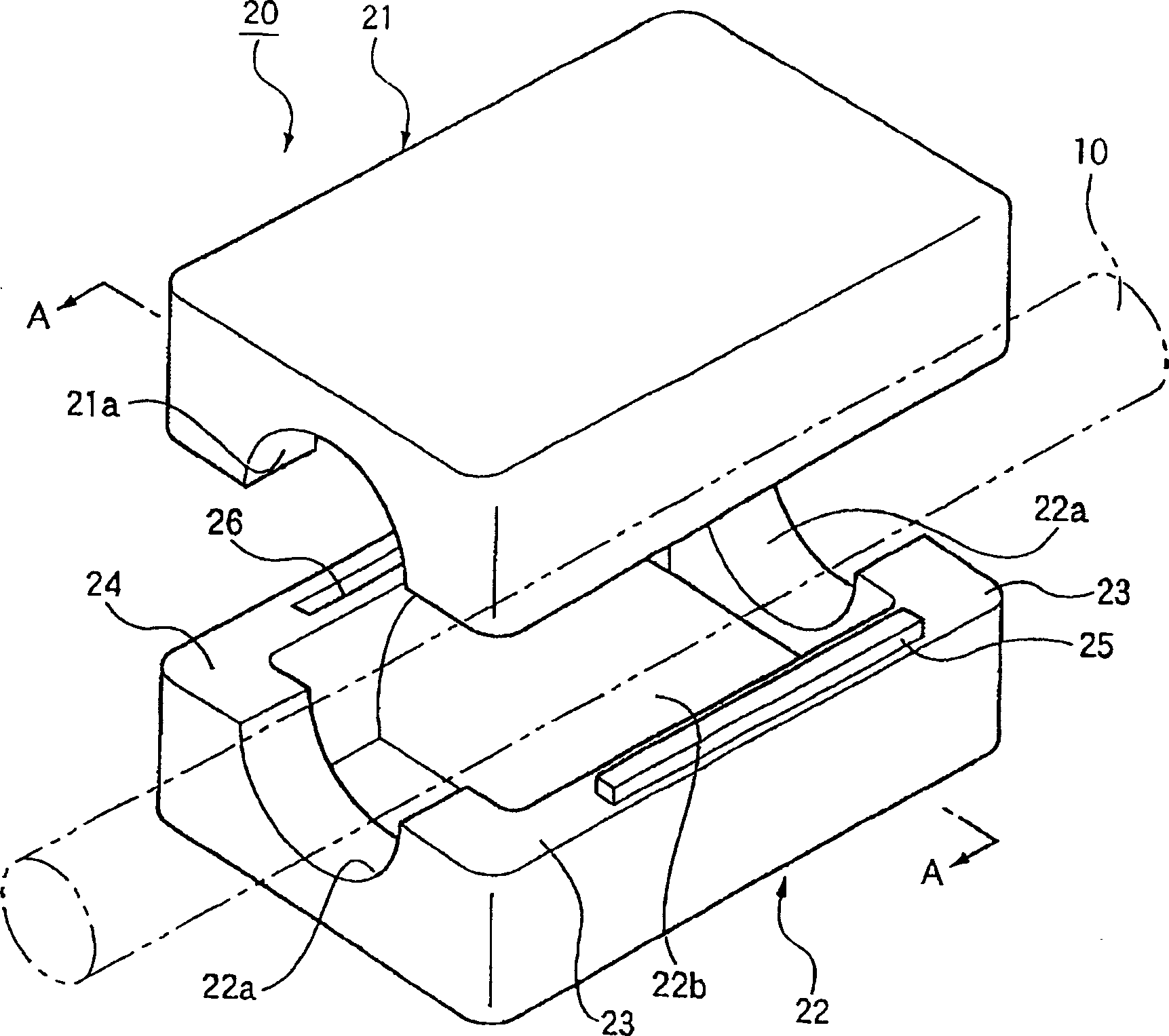

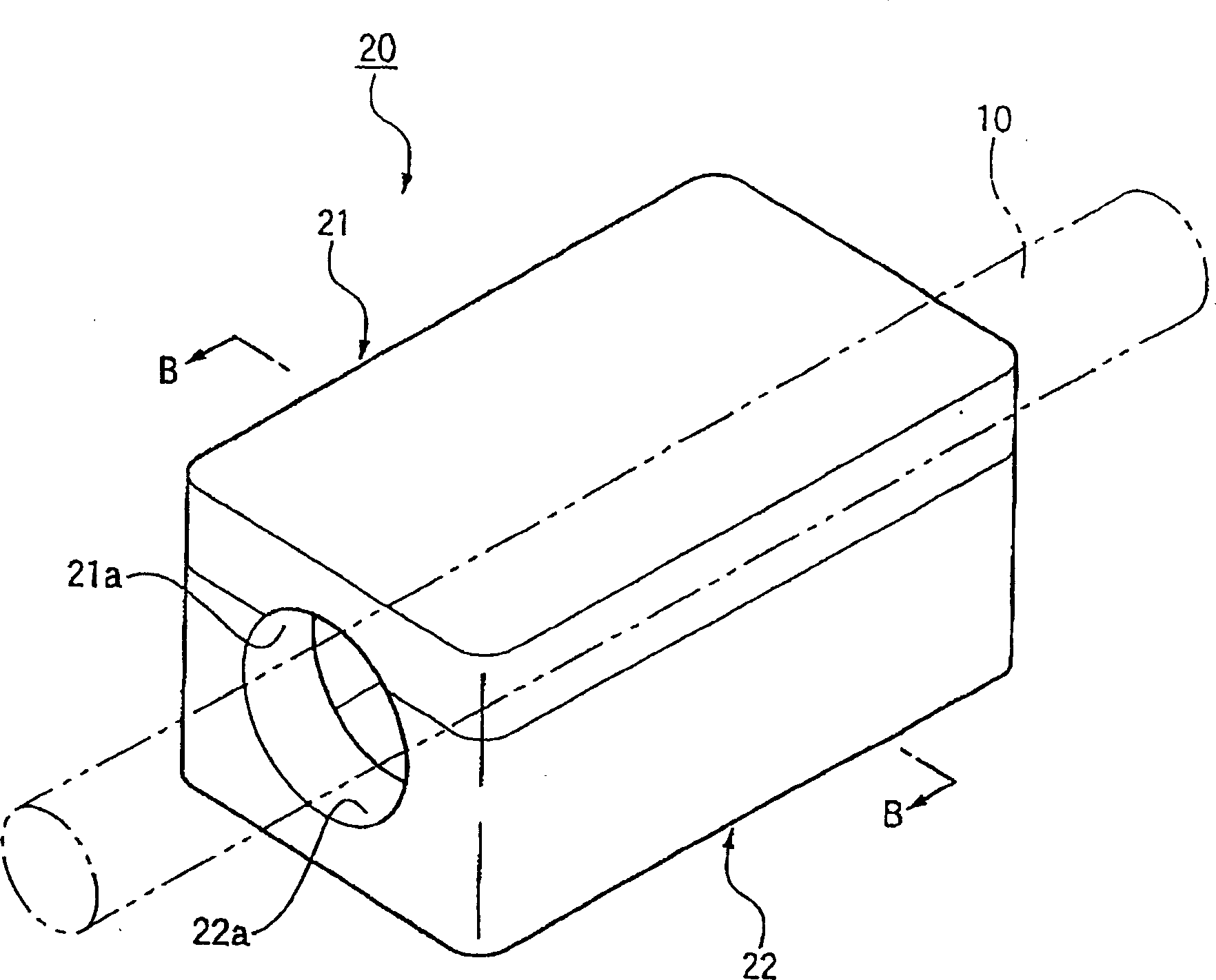

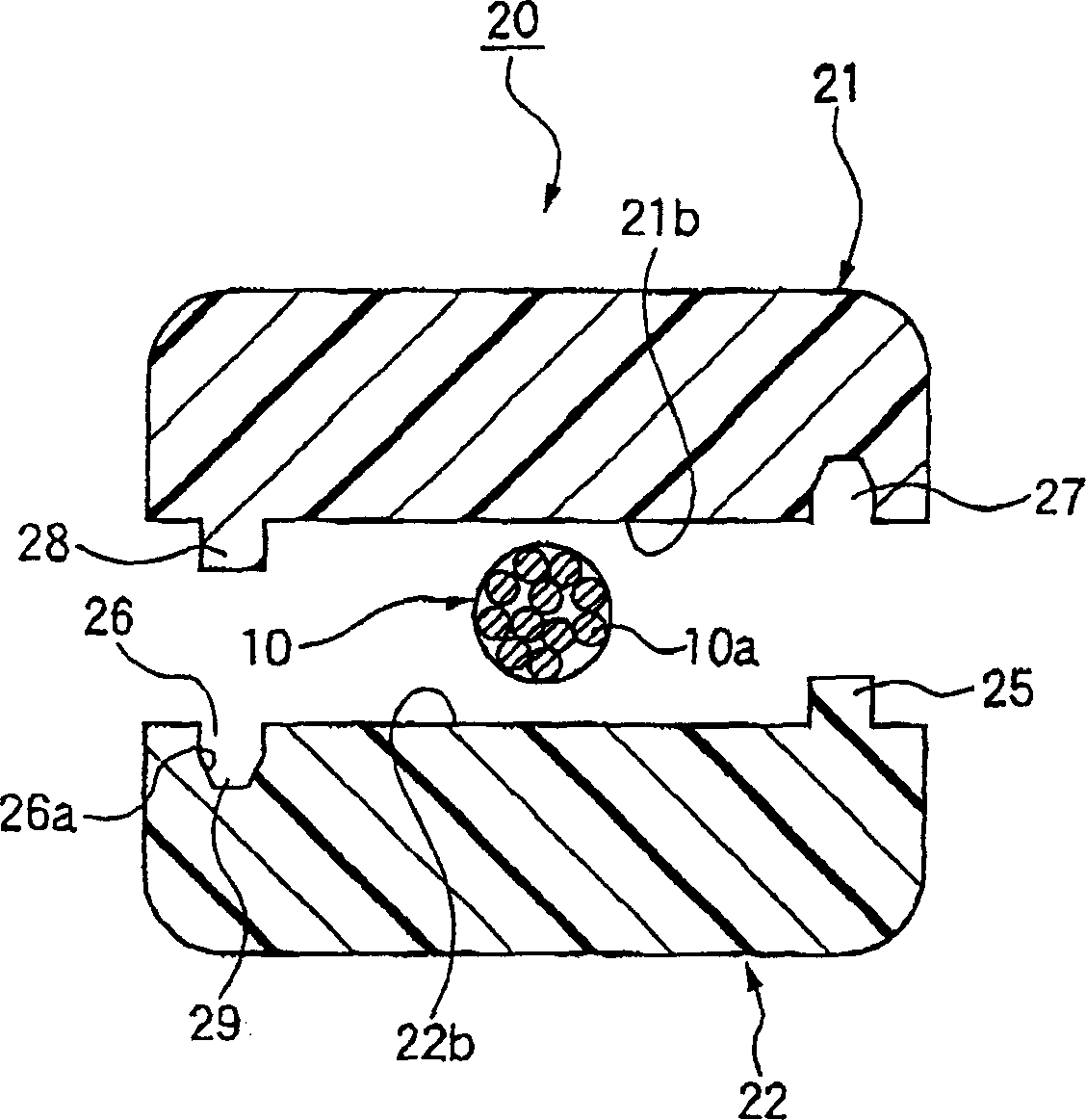

[0083] See below Figure 1 to Figure 5 A first embodiment of the waterproof structure of the covered wire according to the present invention will be described. figure 1 is an exploded perspective view of the waterproof structure of the covered wire according to the embodiment of the present invention. figure 2 is displayed figure 1 Perspective view of the waterstop structure shown after it has been ultrasonically welded. Figure 3A with 3B yes figure 1 Sectional view of the waterstop structure shown. Figure 3A It is an edge showing the state before clamping the covered wire figure 1 3B is a cross-sectional view showing the state of ultrasonic welding of the covered wire figure 2 Cutaway view of B-B. and, Figure 4A is the display assembly figure 1 Sectional view before locking part of the shown waterstop. Figure 4B It is a sectional view after showing the locking part where the water stop structure is fitted. Figure 5 is a perspective view of a water stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com