ODS-alloy of molybdenum, silicon and boron

A boron alloy and alloy technology, applied in the field of molybdenum-silicon-boron alloy, can solve the problems of limited application, difficult component forming, low fracture toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The average particle size measured by the Fisher method is 0.5% by weight of yttrium oxide of 0.8 μm, 96.5% by weight of molybdenum with a particle size of 4.12 μm, 3.1% by weight of silicon with a particle size of 4.41 μm, and a particle size of 0.92 μm boron 1.14 wt% mixed and then mechanically fused. The mechanofusion is carried out in an attritor in the presence of hydrogen. The volume of the ultrafine attritor is 50 liters, and iron-chromium-nickel alloy balls with a mass of 100 kilograms and a diameter of 9 mm are used. Grinding time 10 hours. After mechanical fusion, only molybdenum and yttrium oxide (Y 2 o 3 ). The powder is then introduced into a container made of molybdenum-based alloy. The container is evacuated and welded closed in a vacuum-tight manner. The container and powder are heated in an indirect furnace to a temperature of 1500°C and densified by extrusion. The extrusion ratio was 1:6. The extruded semi-finished products prepared by the abov...

Embodiment 2

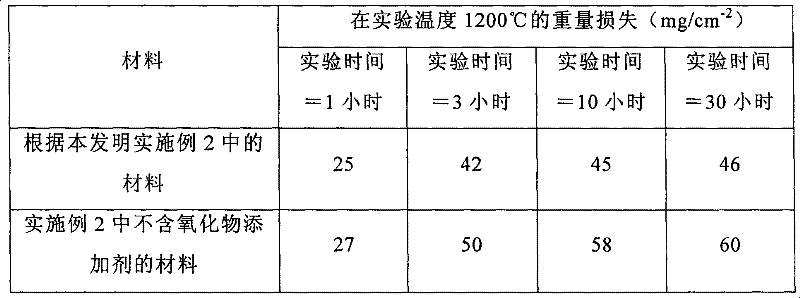

[0016] La(OH) with an average particle size of 0.2 μm 3 0.7% by weight is mixed with 93.9% by weight of molybdenum with a particle size of 4.25 μm, 3.9% by weight of silicon with a particle size of 4.30 μm, and 1.4% by weight of boron with a particle size of 1.15 μm, followed by mechanical fusion. Mechanical fusion was still carried out in the attritor for 10 hours in the presence of hydrogen. The powder was subjected to cold isostatic pressing at 200 MPa (2000 bar), and then densified by sintering at 1350° C. / 5 hours in the presence of hydrogen. Density measurement results show that the theoretical density (8.7g / cm 3 ) of 91%. Since the open porosity is negligible, further densification can be performed directly by hot isostatic pressing without a vessel. The temperature used at this time is 1500° C., the pressure is 198 MPa (1980 bar), and the hot isostatic pressing (HIP) time is 4 hours. The density after hot isostatic pressing is 9.5g / cm 3 , which is equivalent to 99%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com