Alkaline developable resin composition

A resin composition and developing technology, which can be used in photography, instruments, opto-mechanical equipment, etc., and can solve the problems of difficulty in obtaining graphic shapes and fine graphics, and insufficient sensitivity of photosensitive resin compositions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

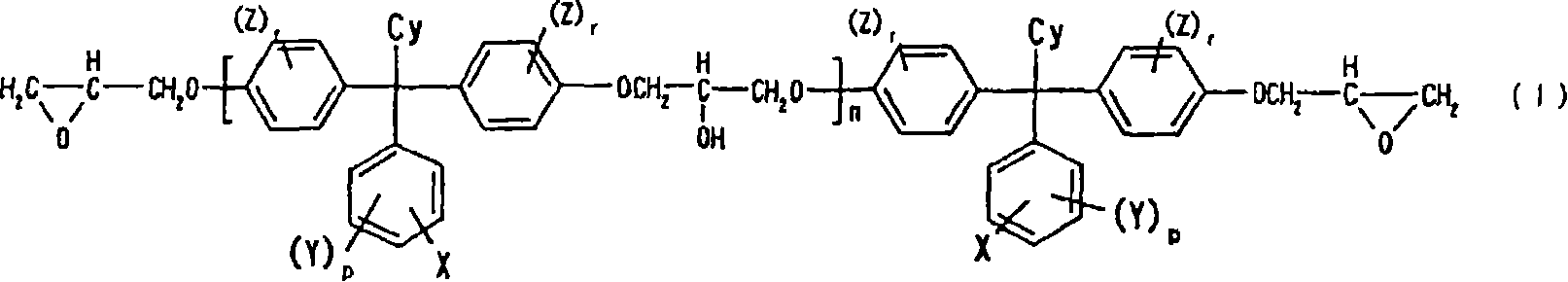

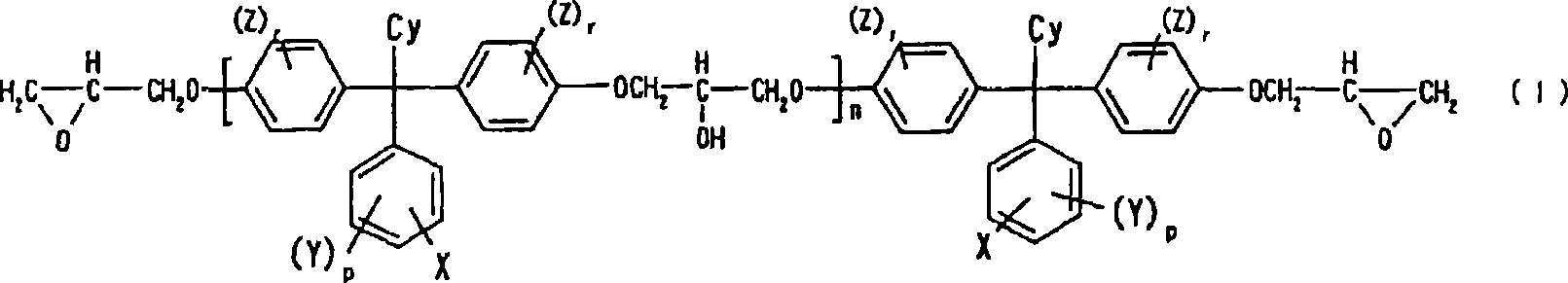

Method used

Image

Examples

Embodiment 1

[0075] [Example 1] Production of Alkaline Developable Resin Composition No.1

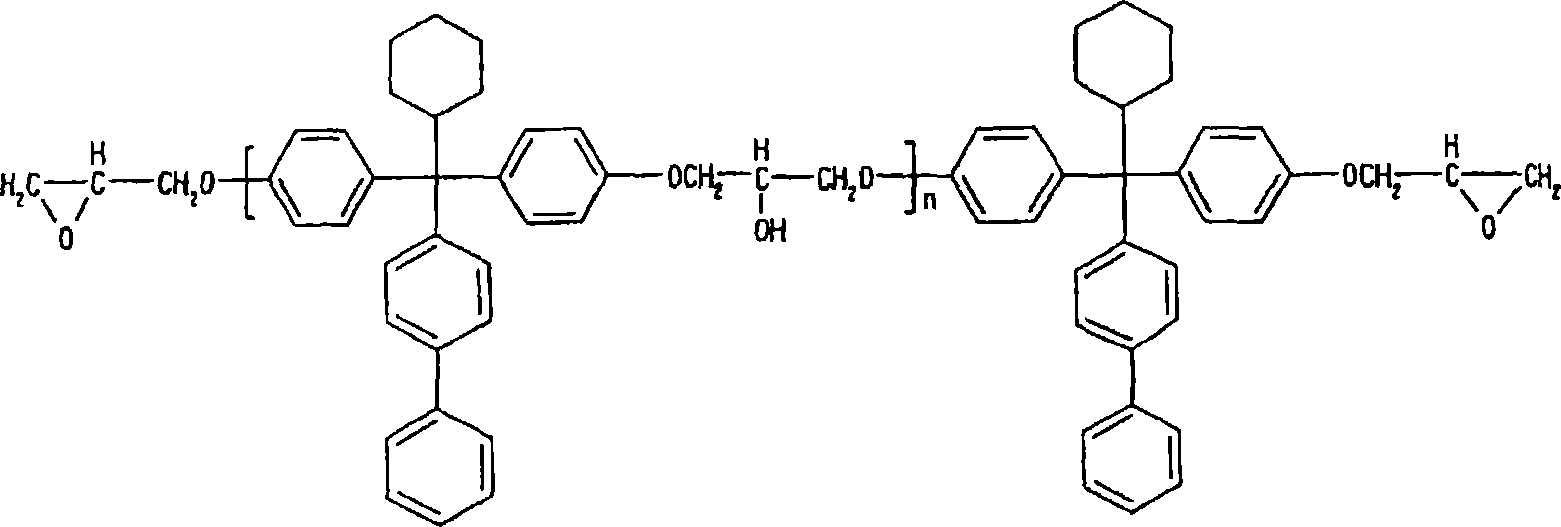

[0076] Production of 1,1-bis(4'-hydroxyphenyl)-1-(1"-biphenyl)-1-cyclohexylmethane

[0077] 70.5 g of biphenylcyclohexyl ketone, 200.7 g of phenol, and 10.15 g of thioacetic acid were added, and 40.0 g of trifluoromethanesulfonic acid was added dropwise at 18° C. over 20 minutes. After reacting at 17-19° C. for 18 hours, 500 g of water was added to stop the reaction, 500 g of toluene was added, the organic layer was washed with water until its pH reached 3-4, and the organic layer was separated. Toluene, water and excess phenol were distilled off. Toluene was added to the residue, and the precipitated solid was filtered, dispersed and washed with toluene to obtain 59.2 g of pale yellow crystals (51% yield). The melting point of the light yellow crystals was 239.5° C., and it was confirmed that the light yellow crystals were the target compound.

[0078] Production of 1,1-bis(4'-glycidoxyphenyl)...

Embodiment 2

[0083] [Example 2] Production of Alkaline Developable Resin Composition No.2

[0084] Add 43g 1,1-bis(4'-epoxypropoxyphenyl)-1-(1"-biphenyl)-1-cyclohexylmethane (compound a), 11g acrylic acid (compound b), 0.05g 2,6-di-tert-butyl-p-cresol, 0.11g tetrabutylammonium acetate and 23g propylene glycol-1-monomethyl ether-2-acetate were stirred at 120°C for 16 hours. Cooled to room temperature, added 35g propylene glycol-1-monomethyl ether-2-acetate and 16g biphenyltetracarboxylic dianhydride (compound d-1), stirred at 120°C for 8 hours.Add 0.7g tetrahydrophthalic anhydride ( Compound d-2), stirred at 120°C for 4 hours, stirred at 100°C for 3 hours, stirred at 80°C for 4 hours, stirred at 60°C for 6 hours, and stirred at 40°C for 11 hours, then added 29g of propylene glycol-1-mono Methyl ether-2-acetate, the target product alkali-developable resin composition No.2 (Mw=8100, Mn=2900, acid value (Solid content) is 89 mgKOH / g).

[0085] In addition, the reaction product contained in ...

Embodiment 3

[0086] [Example 3] Production of Alkaline Developable Resin Composition No.3

[0087] Add 43g 1,1-bis(4'-epoxypropoxyphenyl)-1-(1"-biphenyl)-1-cyclohexylmethane (compound a), 11g acrylic acid (compound b), 0.05g 2,6-di-tert-butyl-p-cresol, 0.11g tetrabutylammonium acetate and 23g propylene glycol-1-monomethyl ether-2-acetate were stirred at 120°C for 16 hours. Cooled to room temperature, added 35g of propylene glycol-1-monomethyl ether-2-acetate, 16g of biphenyltetracarboxylic dianhydride (compound d-1) and 39mg of tetra-n-butylammonium bromide were stirred at 120°C for 4 hours, and at 100°C Stir for 3 hours, stir at 80°C for 4 hours, stir at 60°C for 6 hours, and stir at 40°C for 11 hours, add 29g of propylene glycol-1-monomethyl ether-2-acetate to obtain propylene glycol-1-monomethyl Alkaline developable resin composition No. 3 (Mw = 8600, Mn = 3000, acid value (solid content) 87 mgKOH / g) of the target product in the ether-2-acetate solution form.

[0088] In addition, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com