Novel dust settling chamber

An ash chamber and a new type of technology, applied in the field of ash chamber, can solve the problems of unsatisfactory use effect of ash chamber, deformation of intermediate partition walls, difficult maintenance, etc., and achieve the effects of simple structure, prevention of hole wall cracking, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

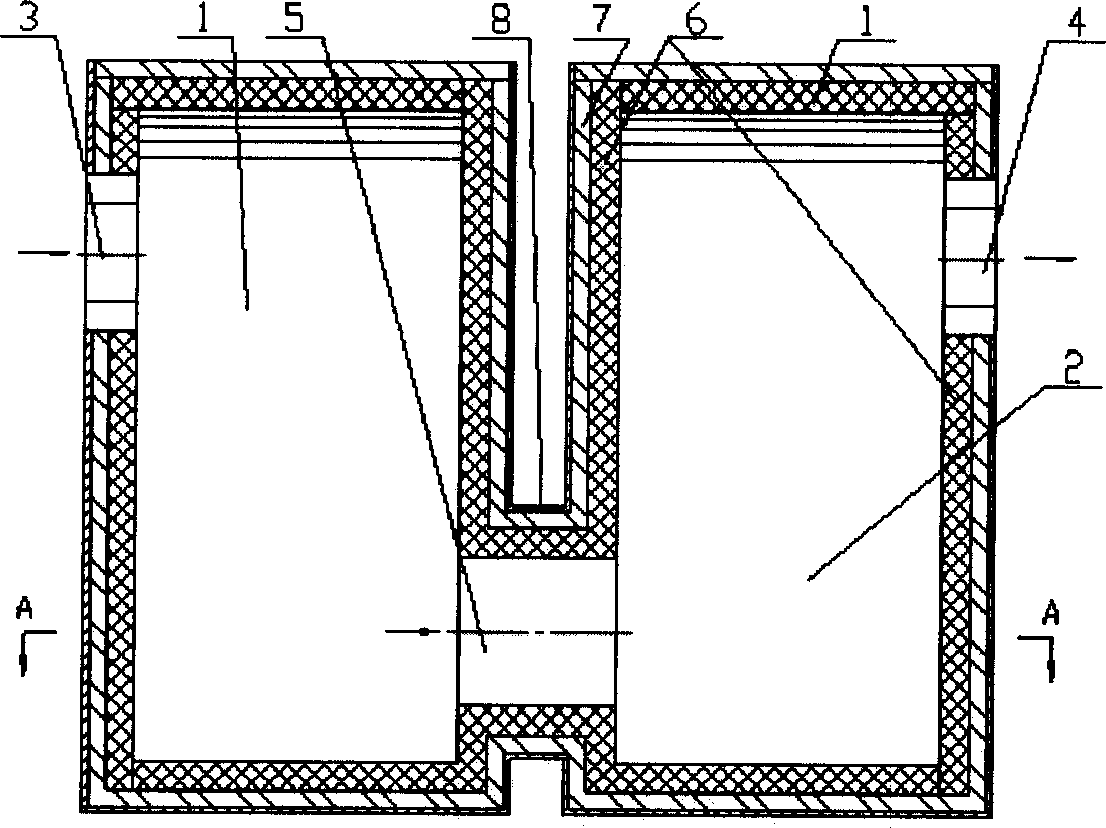

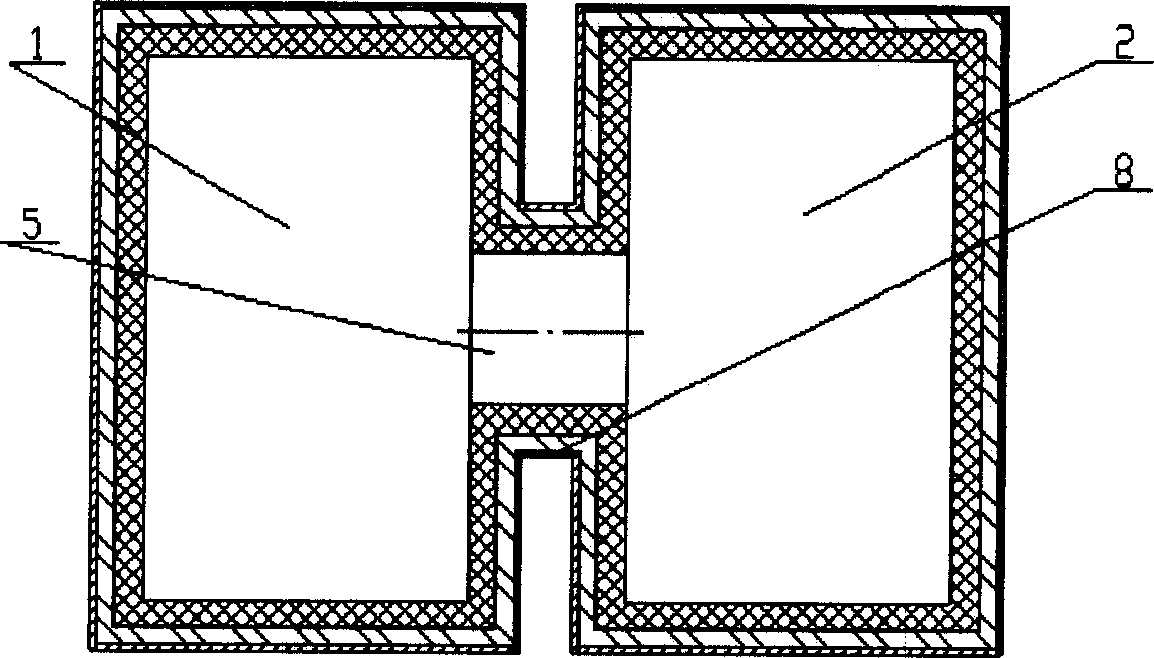

[0009] Embodiment of the present invention: use existing ash chamber building materials to build an independent smoke inlet furnace chamber (1) and an independent smoke outlet furnace chamber (2) respectively, and in the smoke inlet furnace chamber (1) A smoke inlet (3) that can be connected with the exhaust pipe of the rotary calciner is made at the upper position of the rotary calciner, and a smoke outlet (3) that can be connected with the chimney is made at the upper position of the smoke outlet furnace chamber (2) 4), build 1 to 5 flue gas circulation channels at the lower part of the smoke inlet furnace chamber (1) and the smoke outlet furnace chamber (2) that can connect the smoke inlet furnace chamber (1) and the smoke outlet furnace chamber (2) Hole (5), in general, make a flue gas flow hole (5) that can communicate with the smoke furnace chamber (1) and the smoke furnace chamber (2). When making, the smoke furnace chamber (1) ), the inner walls of the smoke outlet cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com