Checking device of the gear-driving balancer

A technology of gear drive and inspection device, which is applied in the direction of machine gear/transmission mechanism testing, etc. It can solve the problems of undetectable gear abnormality, deviation of detection results, long working time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

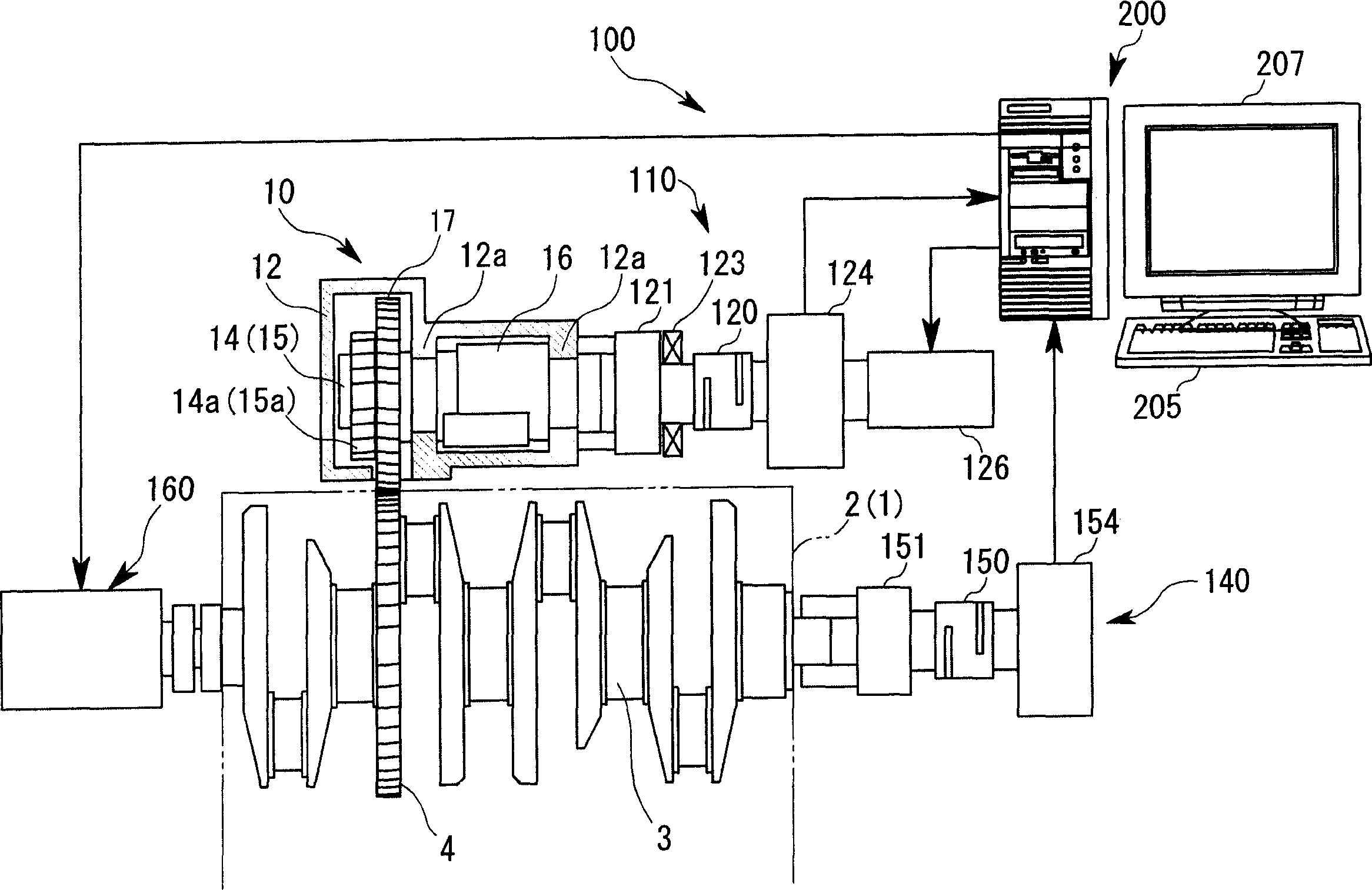

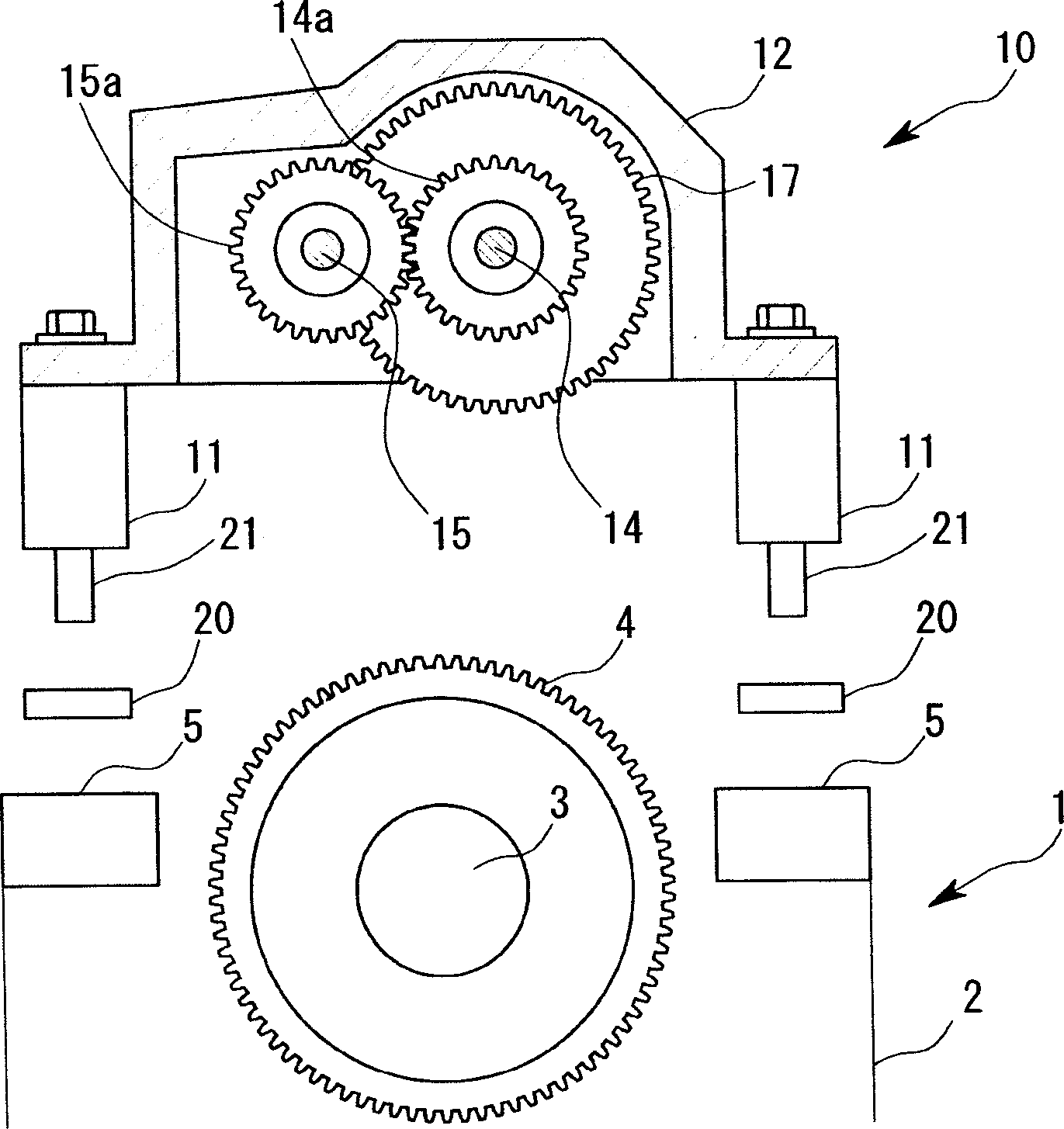

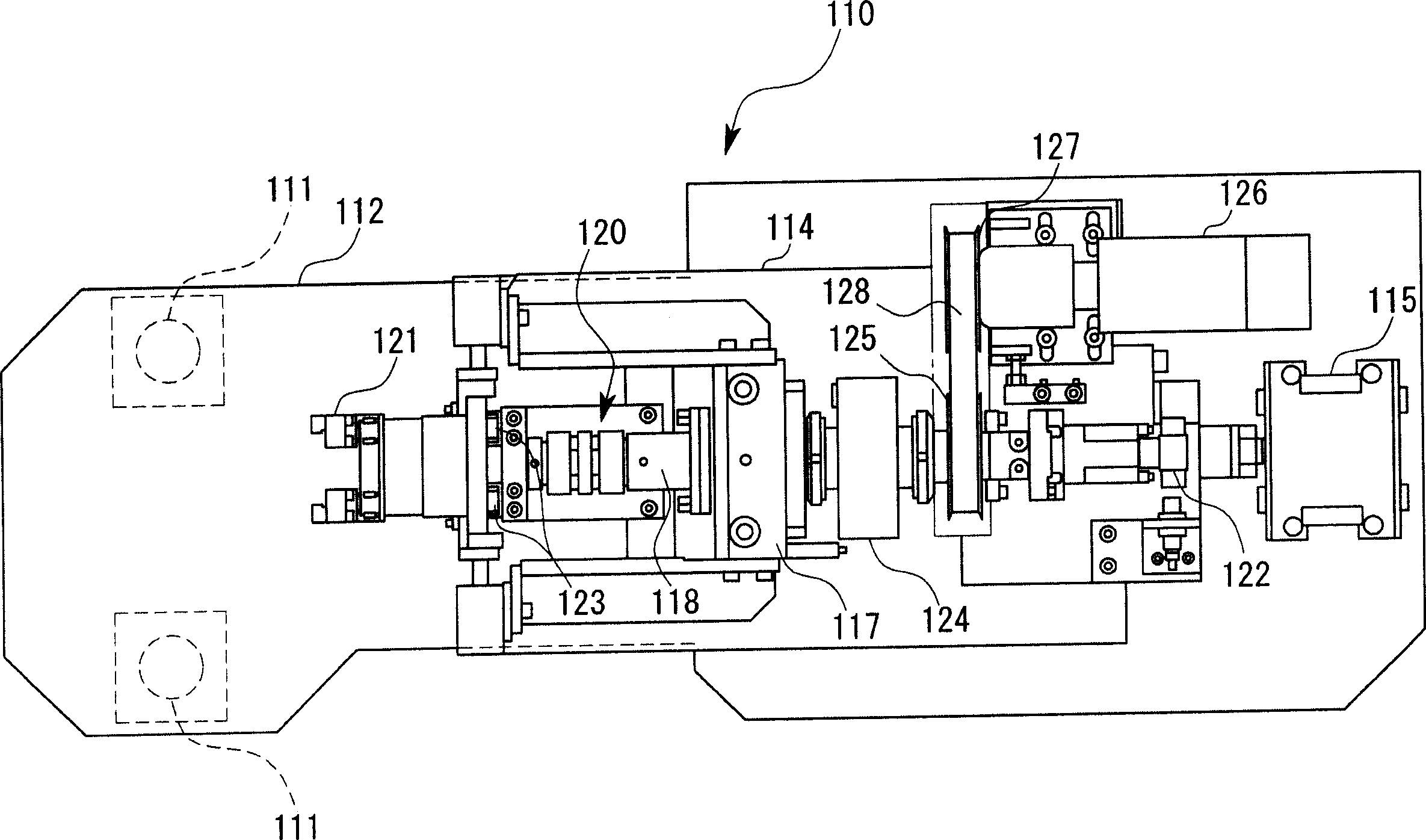

[0040] figure 1 is a structural diagram schematically showing the structure of one embodiment of the present invention, figure 2 is roughly figure 1 A schematic diagram of the installed state of the balancer box 10 and the engine 1.

[0041] refer to figure 1 with figure 2 , the balancer box 10 as the inspection object includes, has 4 cylinders 11 ( figure 2 Only two of them are shown in the figure) housing 12; a pair of balance shafts 14, 15 that are rotatably supported in the housing 12. Each of the balance shafts 14, 15 passes through a pair of bearings 12a formed on the casing 12 (only in the figure 1 shown in the middle) to be supported freely in rotation. Transmission gears 14a, 15a are fixed on the balance shafts 14, 15, and the balance shafts 14, 15 rotate at a rotation ratio of 1:1 through the engagement of the transmission gears 14a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com