Ceramic generator

A generator and ceramic technology, applied in induction generators, electrical components, electromechanical devices, etc., can solve the problems of complex structure, small power generation, and difficult realization, and achieve the effect of reducing volume and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

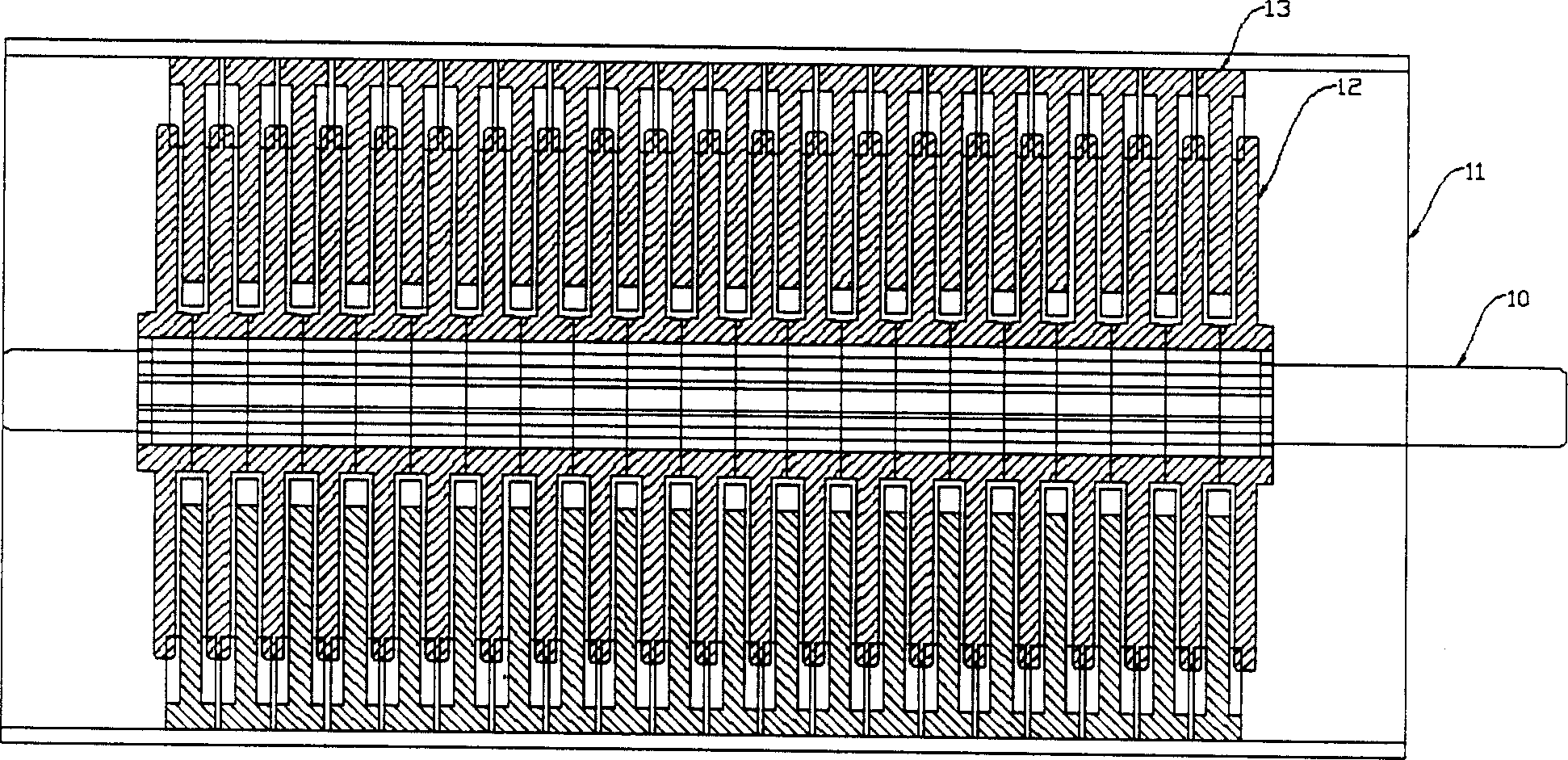

[0022] The ceramic generator consists of a stator mounted on a casing 11 and a rotor mounted on a crankshaft 10 . The stator and the rotor are respectively composed of multiple sets of fixed pole pieces 13 and moving pole pieces 12 (see figure 1 ), are staggered to form a large variable capacitance, the number of fixed pole plates 13 forming the stator and the number of moving pole plates 12 forming the rotor can be selected according to actual needs.

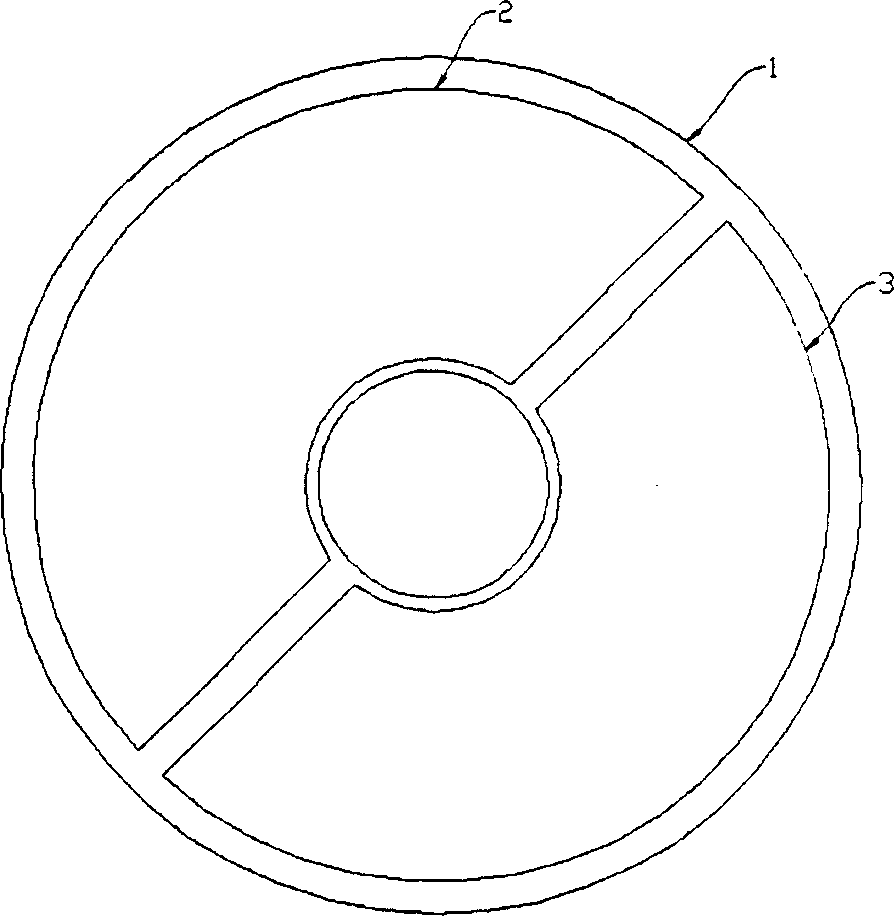

[0023] The structural representation of each pole plate 13 is shown in image 3 , is composed of fixed conductor sheets 2 and 3 fixed on the annular insulating substrate 1, and these two fixed conductor sheets constitute the first fixed electrode a and the second fixed electrode b respectively.

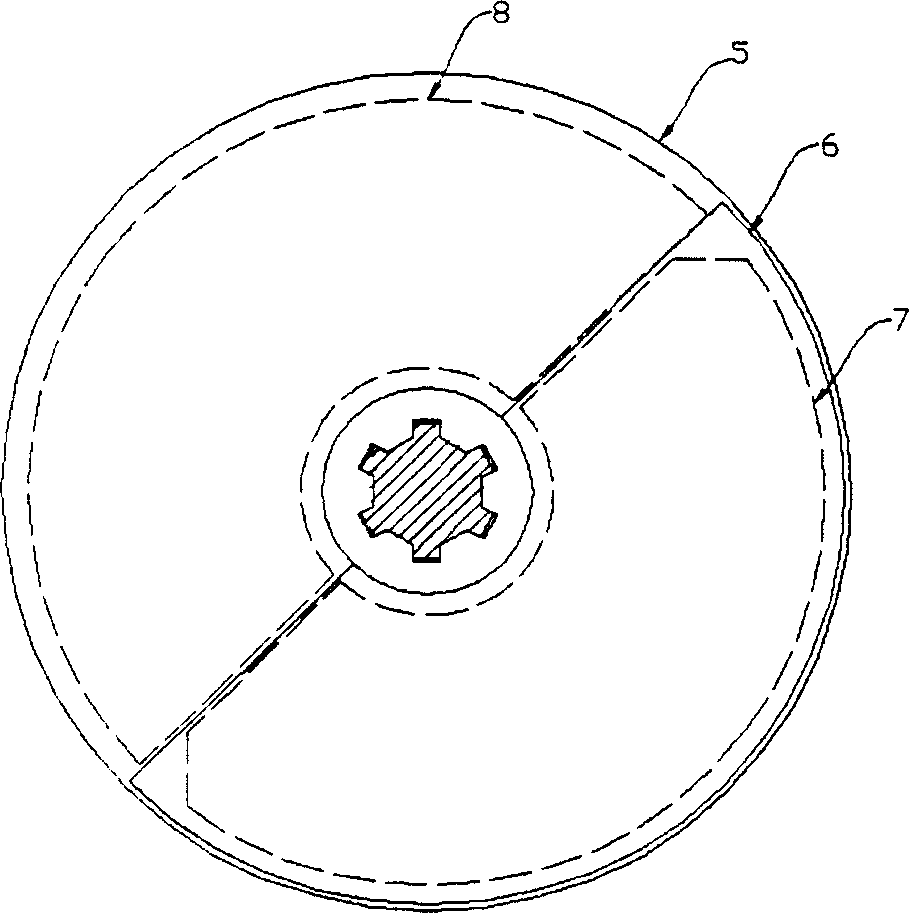

[0024] The structural representation of each moving pole piece 5 is shown in figure 2 , on the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com