Annular acoustic panel

A sound insulation board and annular technology, applied in the field of integral annular sound insulation boards, can solve the problems of noise escaping, sound insulation area loss of function, difficult acoustic processing, matching of acoustic absorption characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

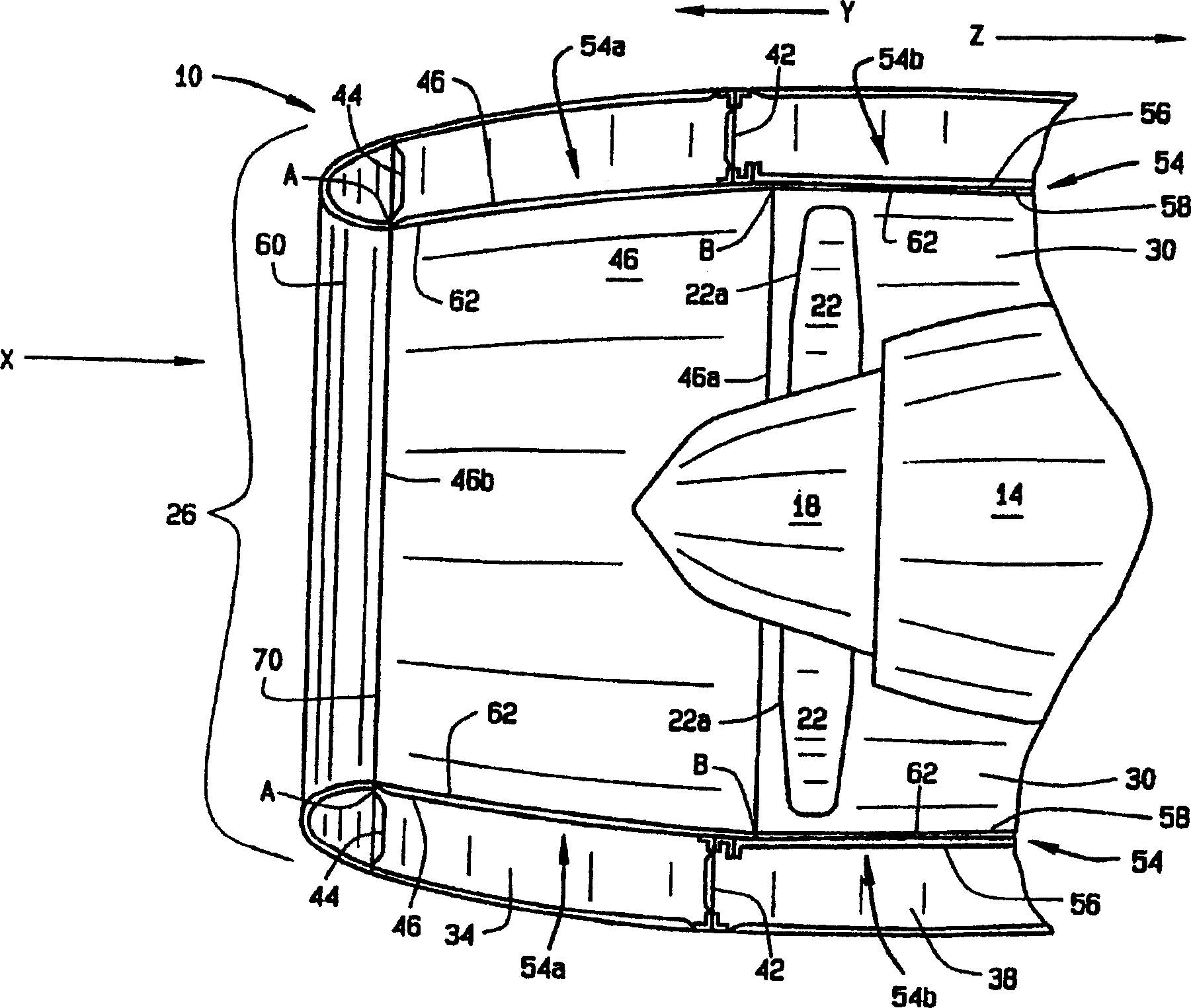

[0010] figure 1 is a partial longitudinal sectional view of an aircraft engine assembly 10 according to the invention. The engine assembly includes an engine 14 , such as a gas turbine, and an associated fan assembly 18 . The fan assembly 18 includes a plurality of circumferentially spaced fan blades 22 . Surrounding the engine 14 and fan blades 22 is a nacelle 26 spaced radially outward from the engine 14 to define an annular passage 30 . Thrust generating air used by the engine assembly 10 enters the engine assembly in the X direction. Typically, air enters nacelle 26 , is compressed by fan blades 22 , and flows through engine 14 via passages 30 .

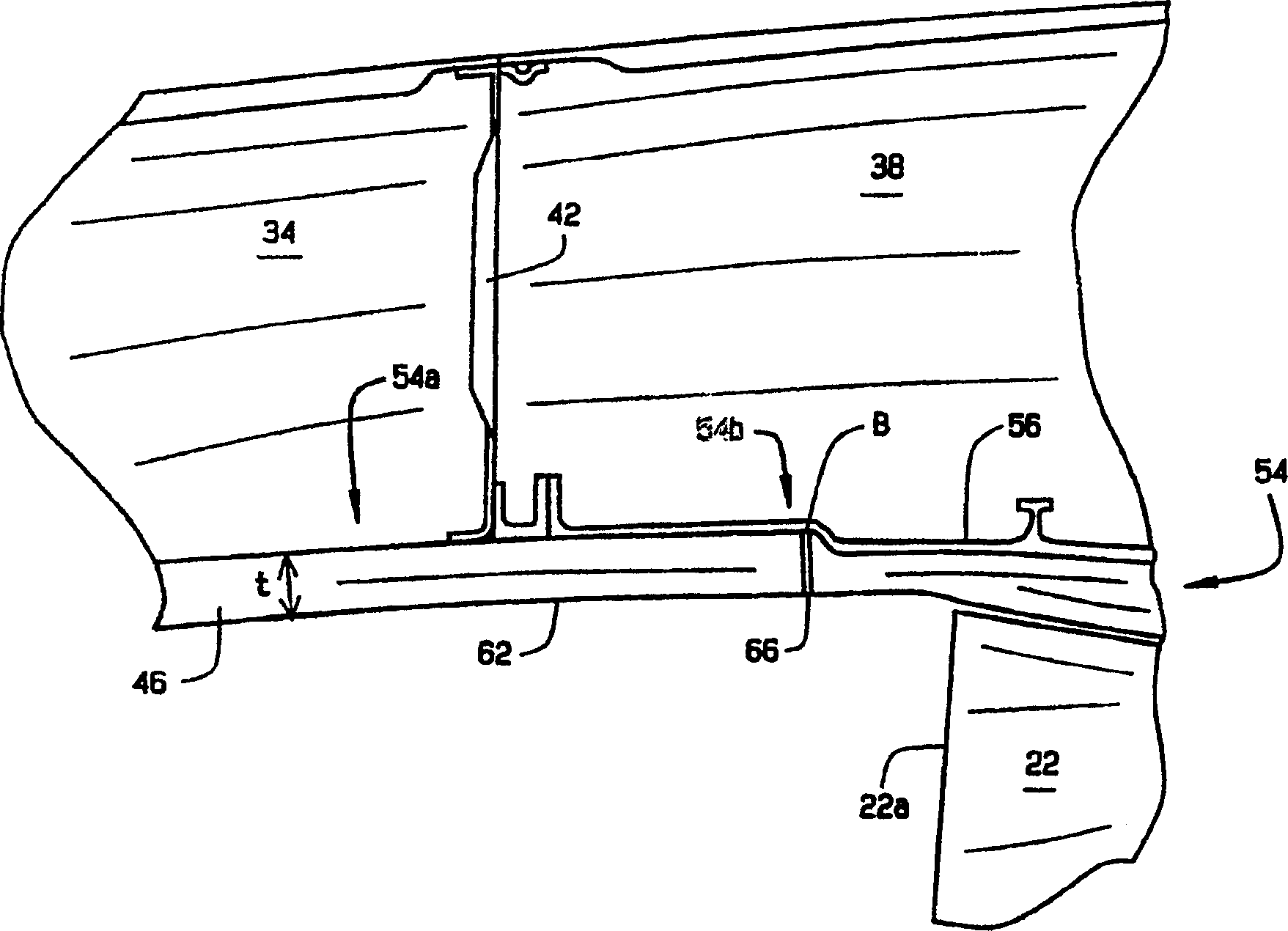

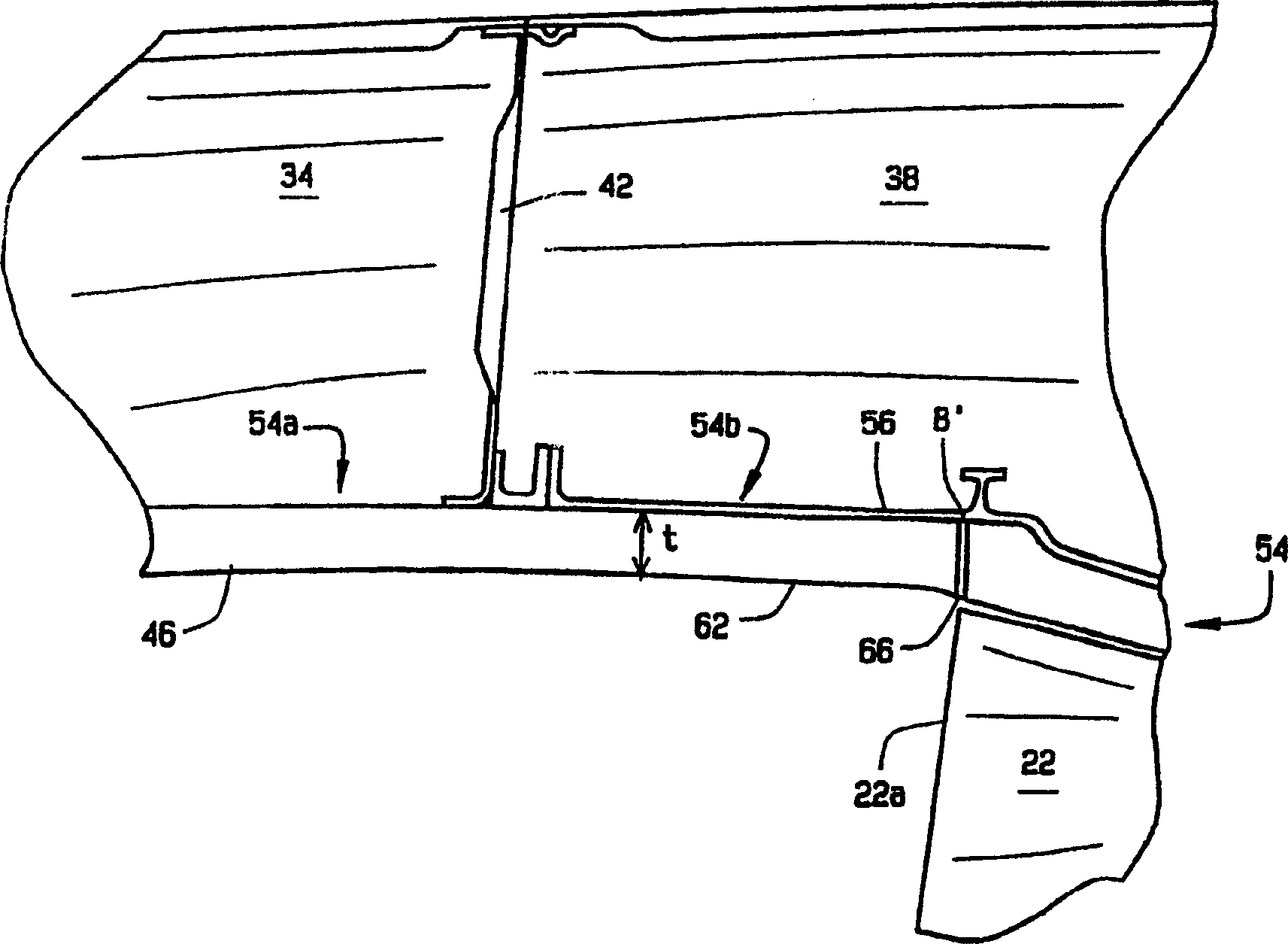

[0011] Nacelle 26 includes an inlet portion 34 connected to a main portion 38 that supports engine 14 and fan assembly 18 within nacelle 26 . The connection between the inlet section 34 and the main section 38 includes a main bulkhead 42 which is used at the connection to provide structural integrity and strength to the nacel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com