Partially azeotropic composition

An azeotropic composition, a technology for the composition, applied in the directions of detergent compositions, non-surface-active detergent compositions, organic non-surface-active detergent compositions, etc., can solve the problem of rising equipment costs, poor cleaning ability of fluorine-containing solvents, Solubility, self-extinguishing restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0215]

[0216] (1) Reflow test

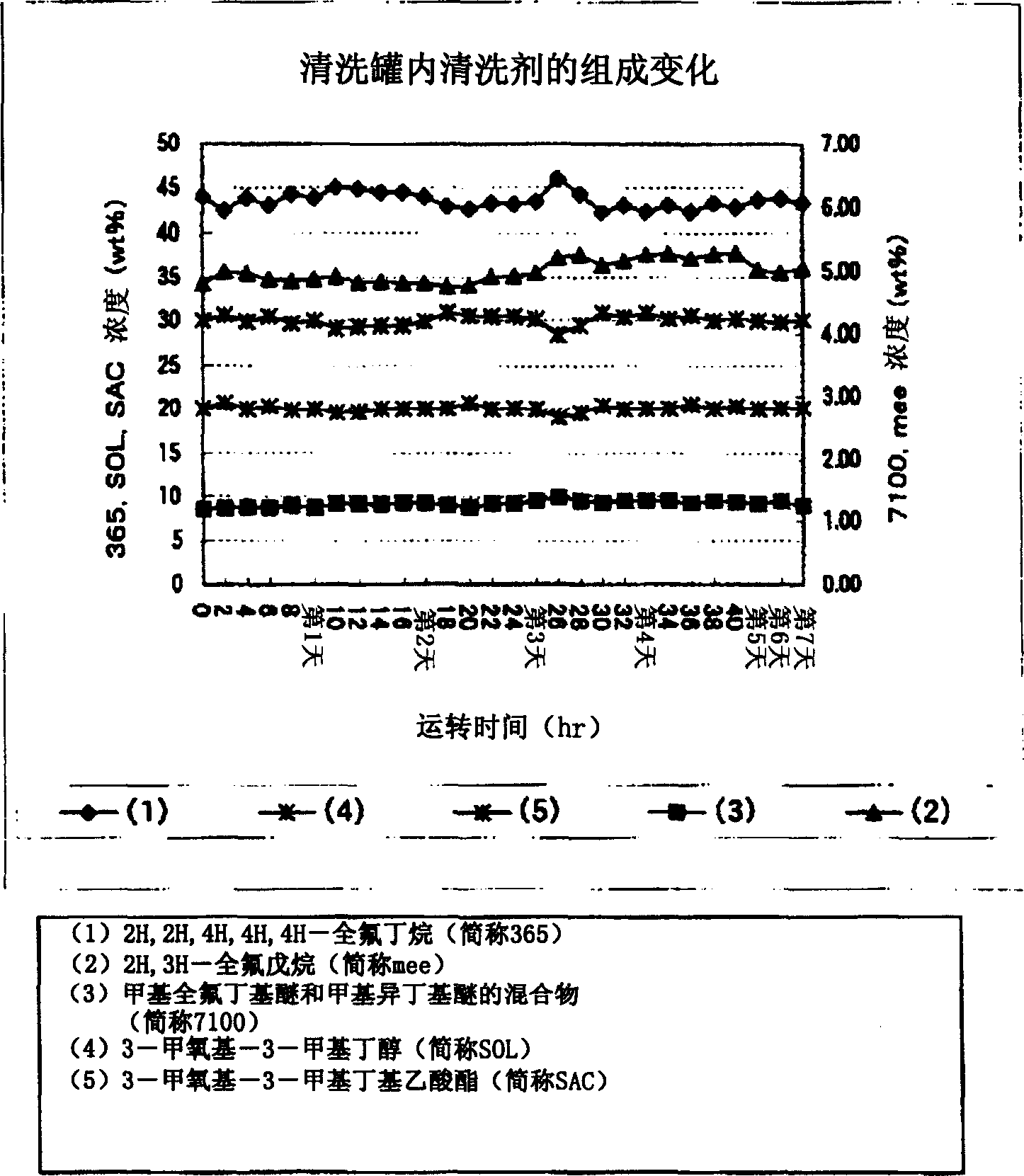

[0217] In order to confirm that the cleaning agents described below are partially azeotropic compositions, and to determine the make-up and rinse composition, a reflux test was performed according to the following gist.

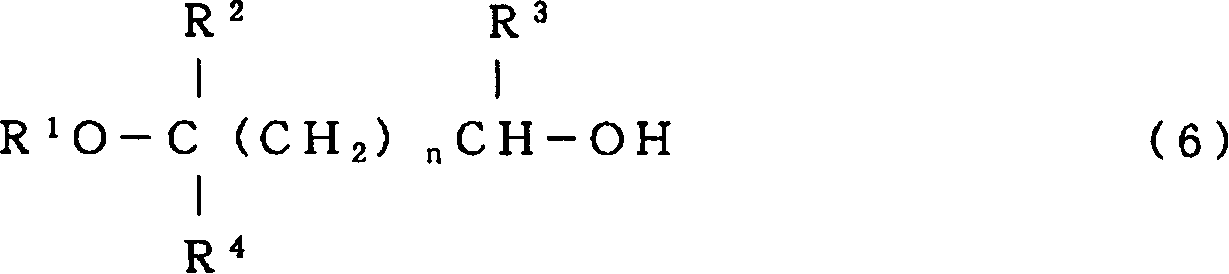

[0218] As the volatile component (A) and the non-volatile component (B) satisfying formula (1) and formula (2), each component of Table 1 and Table 2 was mixed with the composition described in each table, and the cleaning agent was prepared. 300ml of the cleaning agent obtained was dropped into a 500ml eggplant-shaped flask equipped with a reflux device, and after reflux for 2 hours, the condensate distilled off from the top was sampled, and its composition was analyzed by gas chromatography. The obtained analytical value is used as the composition of the make-up solution and the rinse solution. The composition analysis values at this time are shown in Table 1 and Table 2.

[0219] As shown in Table 1, any of the compo...

Embodiment 6~24

[0266] Each component was mixed with the composition shown in Table 5, and the cleaning agent which has the desired partial azeotropic composition was obtained. Table 5 shows the results of the above-mentioned (4) cleaning test and (5) flux cleaning test for each cleaning agent. By using 2H, 2H, 4H, 4H, 4H-perfluorobutane (HFC365mfc) in combination as the component (A1), one or more of the components selected from the number of fluorine atoms and the number of hydrogen atoms in the molecule as the component (A2) Compared with the compound of 2 or more chlorine-free fluorine compounds, and the vapor pressure at 20°C as component (B) is lower than 1.33×10 3 A compound of Pa can be used to obtain a cleaning agent with excellent solubility in processing oil and flux.

Embodiment 25~37

[0274] Each component was mixed with the composition shown in Table 6, and the cleaning agent which has the desired partial azeotropic composition was obtained. Table 6 shows the results of the above-mentioned (6) fire point measurement for each cleaning agent. Combination of component (A1) 2H, 2H, 4H, 4H, 4H-perfluorobutane (HFC365mfc), component (A2) one or two or more selected from the ratio of the number of fluorine atoms in the molecule to the number of hydrogen atoms is 2 or more Compounds of fluorine compounds that do not contain chlorine, and component (B) has a vapor pressure at 20°C of less than 1.33×10 3 The compound of Pa confirmed that its ignition point disappeared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com