System for measuring phase fraction and phase interface in multiphase pipe flow by using monofilament capacitance probe

A single-wire capacitance probe and measurement system technology, applied in the direction of material capacitance, etc., can solve problems such as changes and affect the dielectric constant of liquid phase, and achieve the effect of eliminating the influence of measurement results and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

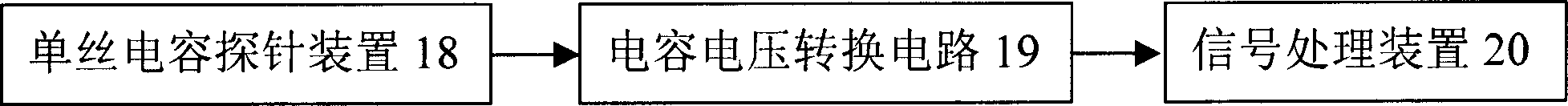

[0016] see figure 1 , the present invention comprises a monofilament capacitive probe device 18 and a capacitive voltage conversion circuit 19 and a signal processing device 20 connected with the monofilament capacitive probe device 18, and the capacitive voltage conversion circuit 19 converts the monofilament capacitive probe device 18 The capacitance value of the silk capacitive probe is converted into a DC voltage, and the voltage value is transmitted to the signal processing device 20, and the signal processing device 20 realizes the control of opening and closing of the capacitance-voltage conversion circuit 19 and realizes data processing, display, storage and printing and other functions.

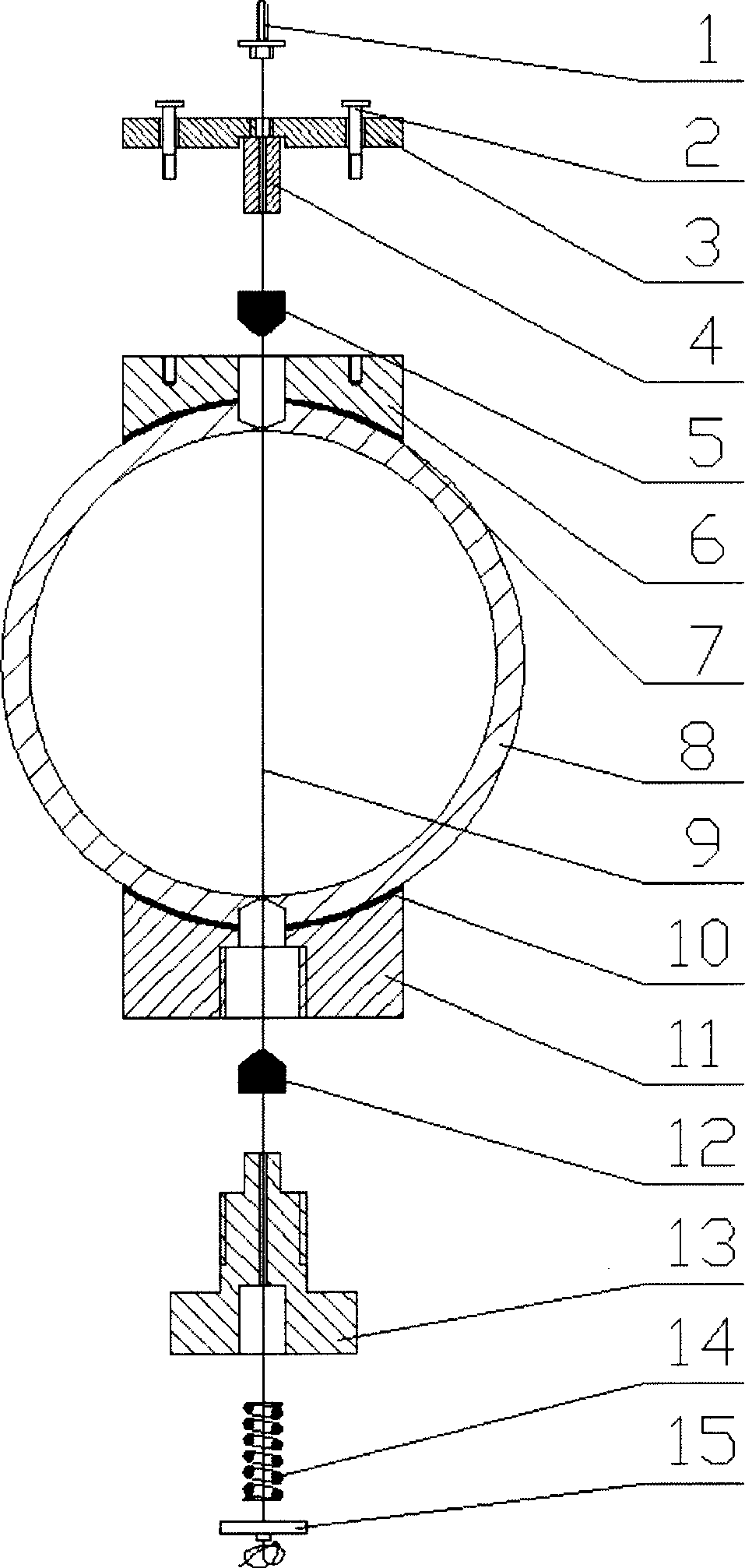

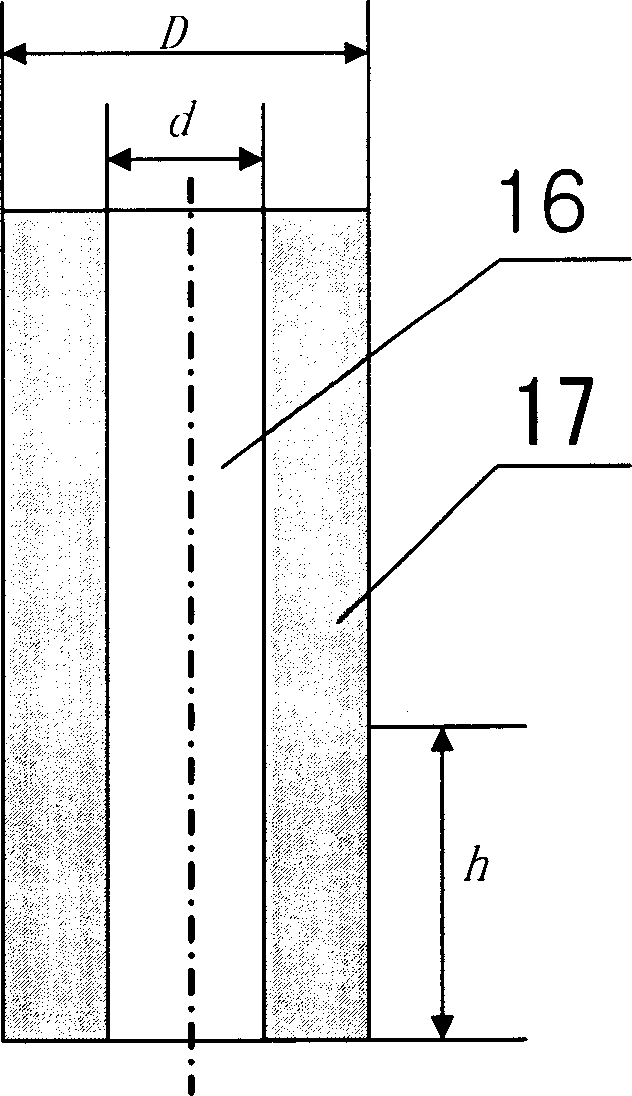

[0017] see figure 2 , the monofilament capacitive probe device 18 of the present invention comprises the monofi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com