Air purification wall

An air and photocatalytic technology, applied in air conditioning systems, space heating and ventilation, chemical instruments and methods, etc., can solve the problems of few devices, difficult to achieve, helpless and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

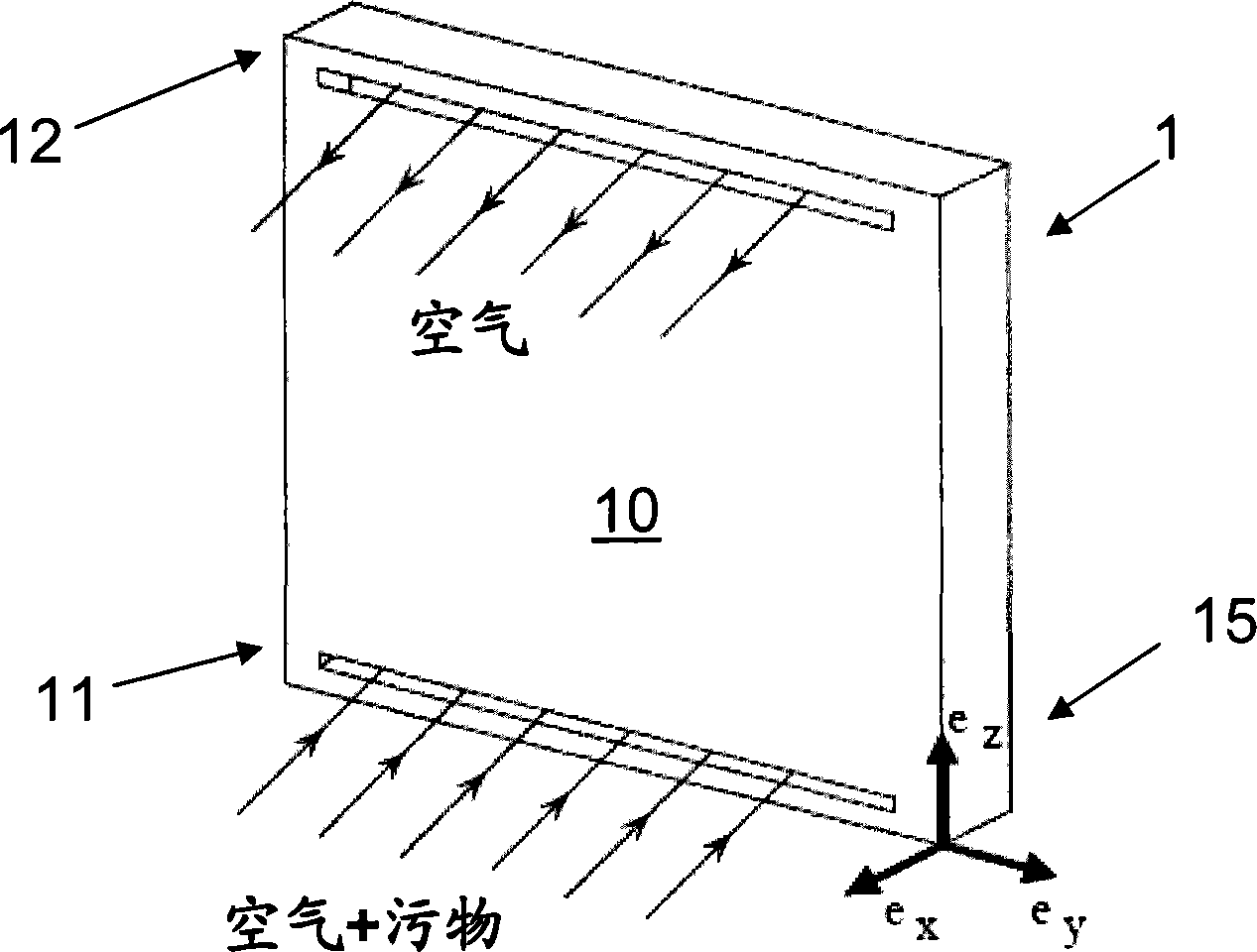

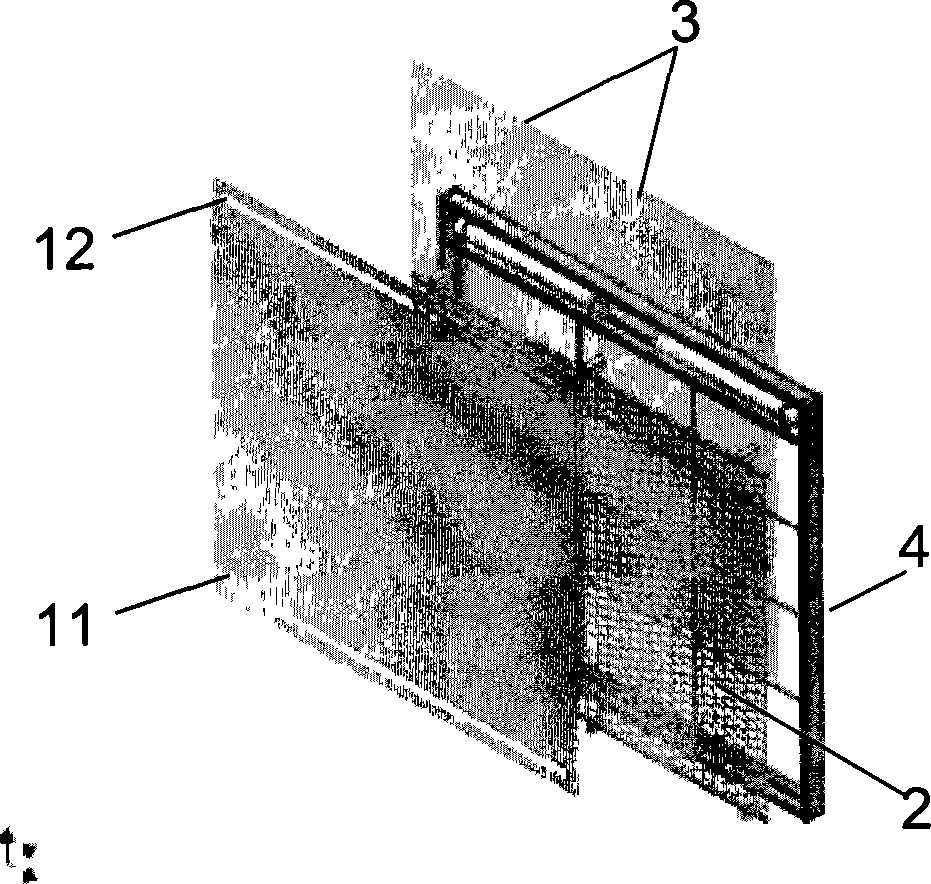

[0060] [36] figure 1 with figure 2 The working principle of the shown air-purifying wall 1 is heterogeneous photocatalysis in contact with titanium dioxide. The device includes an active wall 1, which adopts an open-loop working mode, and the active wall includes:

[0061] - an air inlet 11 located in the lower part of the front surface 10 of the active wall, through which the mixture of air and any possible pollutants enters the device;

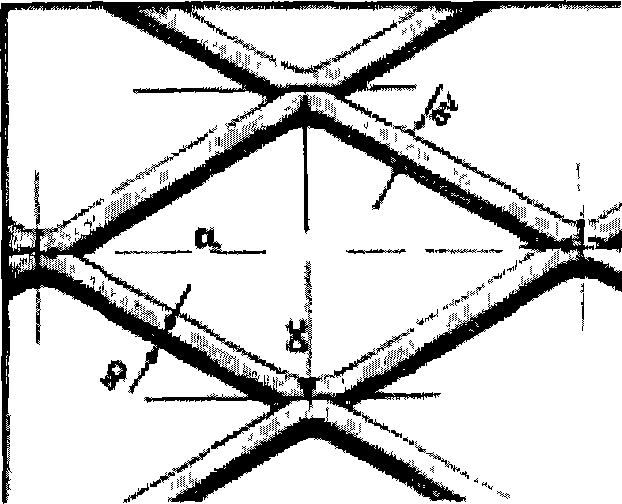

[0062] - one or several grids 2 located inside the active wall, they are made of porous metal, and titanium dioxide is deposited thereon, the grid is irradiated by the irradiation device with UVA lamp 3, to excite the titanium dioxide film layer;

[0063] - An opening 12 at the top of the front face 10 of the active wall, through which the air which has been cleaned of pollutants is discharged. The air flow is generated either by a fan (convection or forced circulation) or due to a temperature rise (natural circulation) which is due to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com