Method of fabrication and device comprising elongated nanosize elements

A nanoscale, component technology that is used in semiconductor/solid state device fabrication, chemical instruments and methods, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

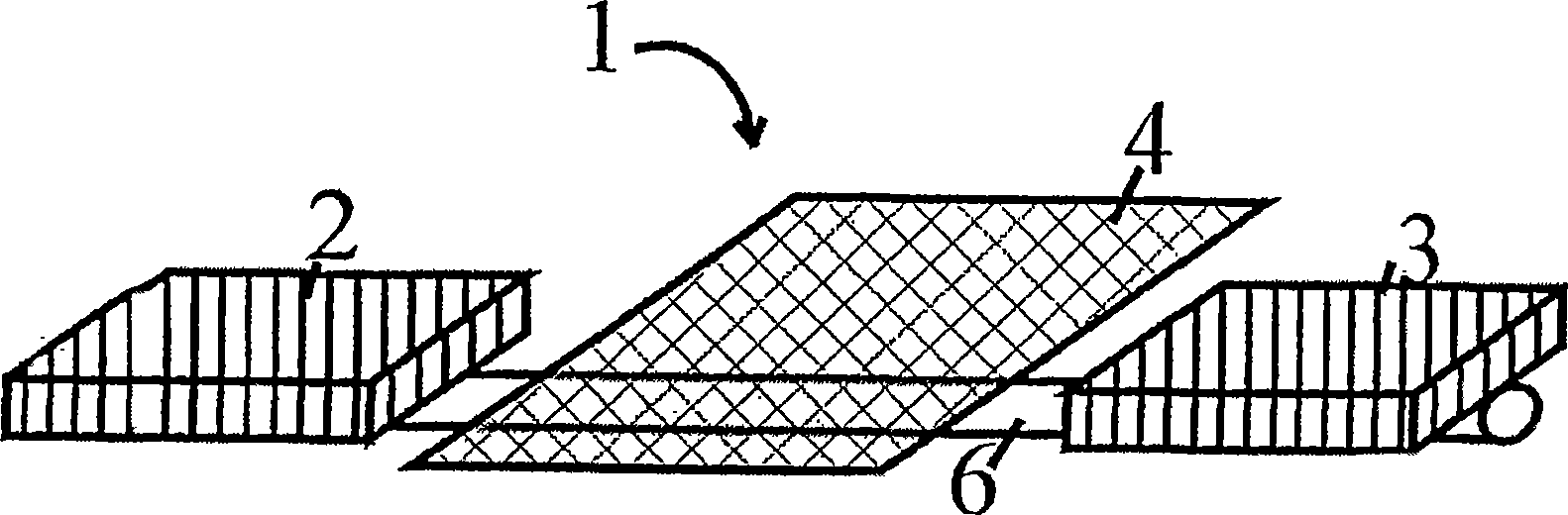

[0085] refer to figure 1 , 2 and 3, illustrate the main process steps involved in the fabrication of a simple device and an example of a simple device, namely the fabrication of a field effect transistor (FET).

[0086] figure 1 Denotes FET part 1. The device is a three terminal device comprising a source 2 and drain 3 and a gate 4 electrically connected to wires (not shown). Electromagnetic semiconductor material for source and drain - Ga 1-x mn x As (GaMnAs), but may also be made of other materials suitable for semiconductors. The source 2 and the drain 3 are connected through a single-walled nanotube 6 . The electrodes of source 2, drain 3 and gate 4 may be semiconductor elements formed from the epitaxial layer above the nanotubes. A single electronic transistor device can be obtained with a similar design.

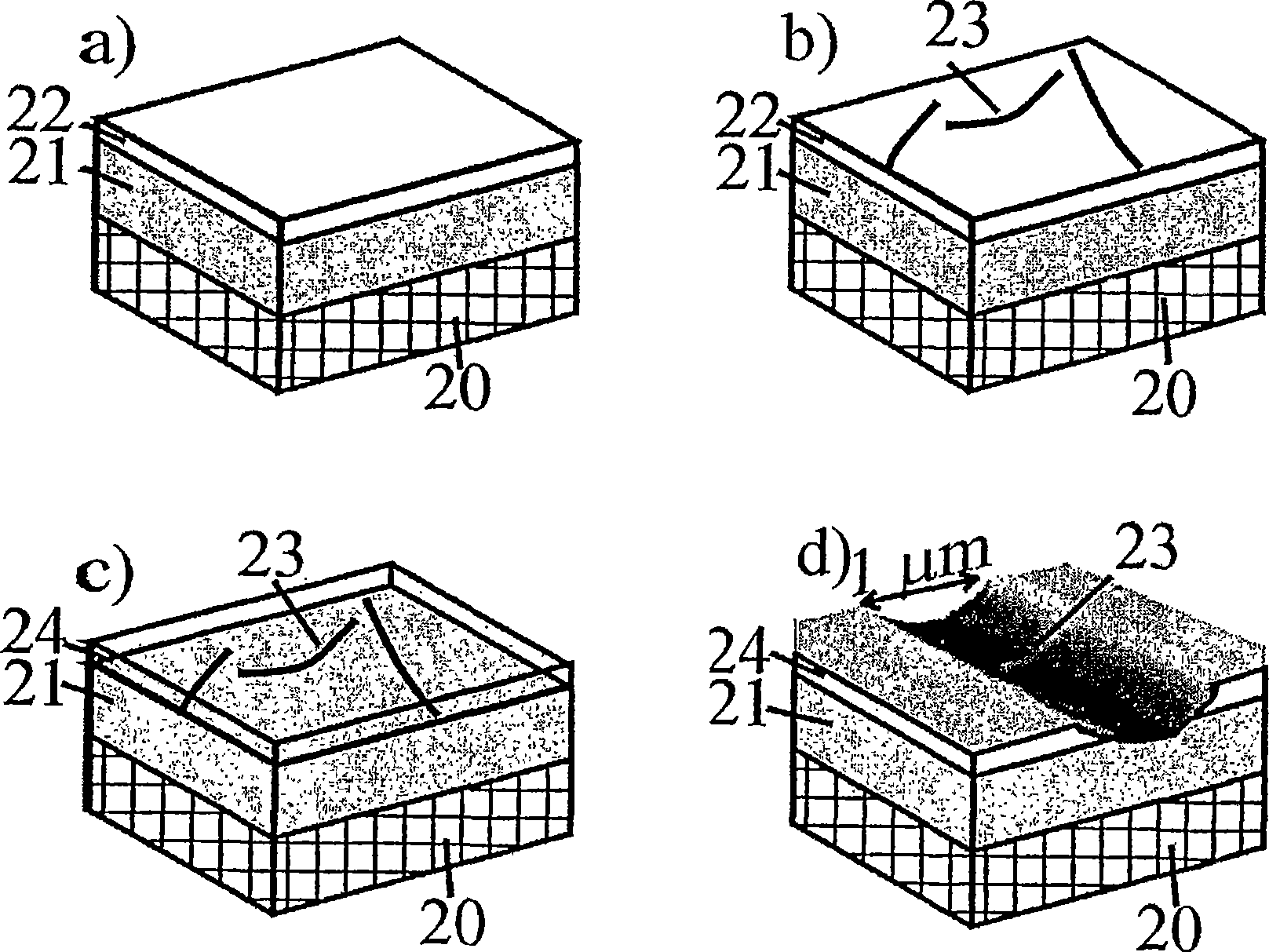

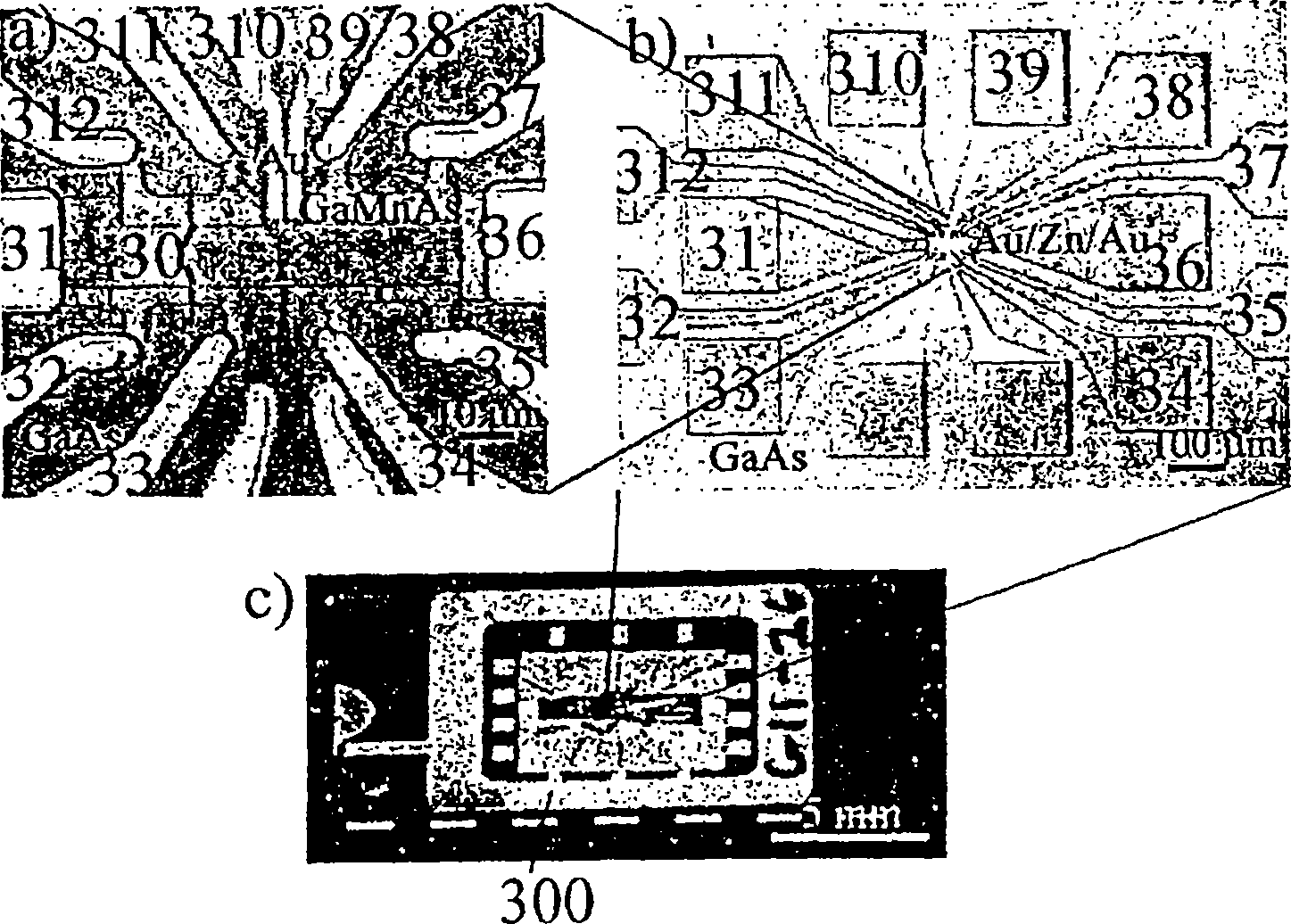

[0087] now refer to fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com