Chemical grooving technical process and device using rotation corrosion liquid spraying method

A process method and chemical technology, which is applied in the field of chemical trenching process and device of rotary corrosion spraying, can solve problems affecting the performance of silicon wafers of power electronic devices, flashover faults, short circuits between doors and windows, etc., so as to reduce post-processing costs, Increased productivity and improved safety conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

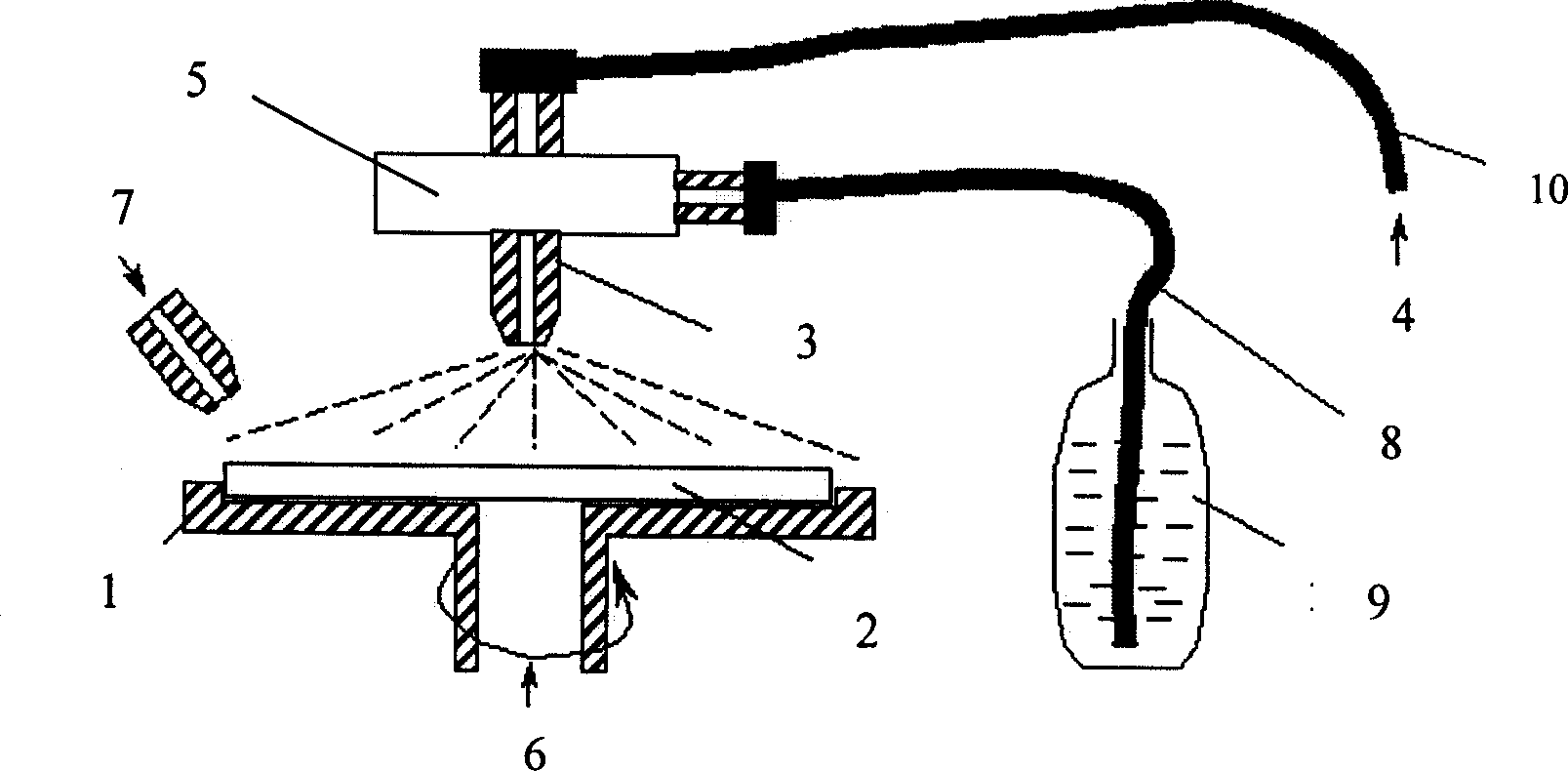

[0041]The device proposed according to the above method is: at least one rotatable chassis 1, the power electronic device silicon wafer 2 to be processed is fixed on the chassis 1, and the power electronic device silicon wafer 2 is driven by the chassis 1 to rotate at a constant speed. A nozzle 3 for spraying corrosive acid is provided above the sheet 2, and the nozzle 3 is connected with a compressed air 4 through the connecting pipe 10, and the compressed air 4 enters the nozzle 3 through the connecting pipe 10, and passes through the nozzle 3 in the form of mist toward the power electronics downward. The surface of the device silicon wafer 2 is ejected; there is also a siphon device 5 on the nozzle, and a siphon tube 8 is arranged on the siphon device 5, and the siphon tube 8 is inserted into the acid storage tank 9 containing the corrosive acid solution, and the siphon device 5 is used for inhaling the corrosive acid solution And make it atomized, and spray it uniformly to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com