Method of treating raw material for producing acerate coke

A needle coke and pretreatment technology, which is applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., can solve the problems of loss of aromatics, high severity of hydrogenation, and ineffective use of hydrogen, and achieve saving The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

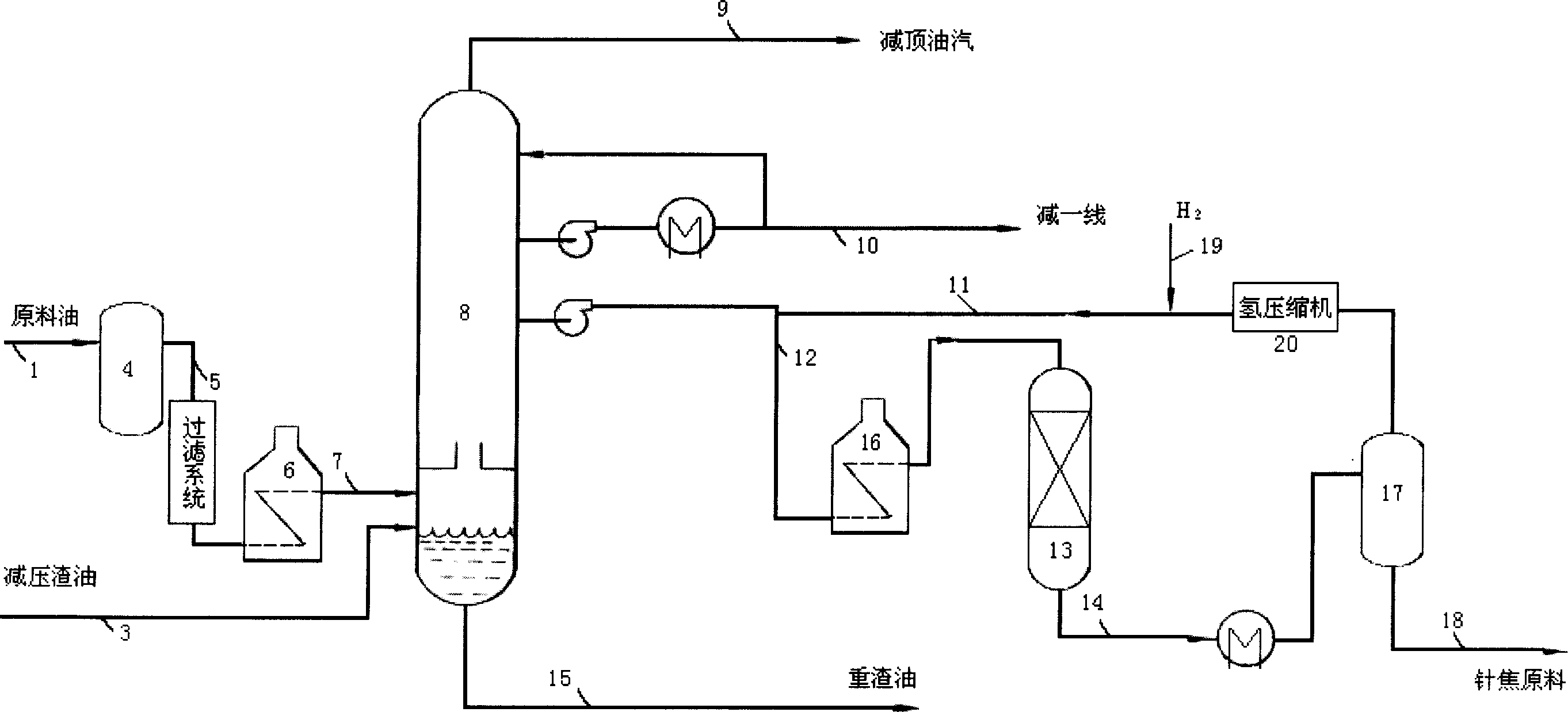

[0015] Method provided by the invention is implemented like this:

[0016] The raw material oil is firstly removed by filtration and vacuum distillation to remove heavy non-ideal components such as asphaltene, colloid and part of ash, and light non-ideal components such as diesel fraction, wherein the light non-ideal components are removed from the top of the vacuum tower The heavy non-ideal components are extracted from the bottom of the tower, and the remaining ideal components are extracted from the tower to contact with hydrogen and hydrogenation catalysts, and the hydrogenation reactants are separated to obtain the raw materials for producing needle coke.

[0017] The feed oil of the present invention is selected from one or more of heavy distillate oil, catalytic cracking oil slurry or clarified oil, steam cracking residue, and thermal cracking residue, wherein the heavy distillate is a wax oil fraction with a distillation range of 270 ~500°C. The sulfur content of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com