Fabricating method for densifying jetting deposited square shaped blank in large size, and equipment

A technology of spray deposition and square blank, which is applied in the field of devices for realizing the densification processing method, can solve the problems of densification of difficult blanks, limited lateral deformation, lack of equipment, etc., and achieve simple structure, reliable performance and convenient manufacture of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

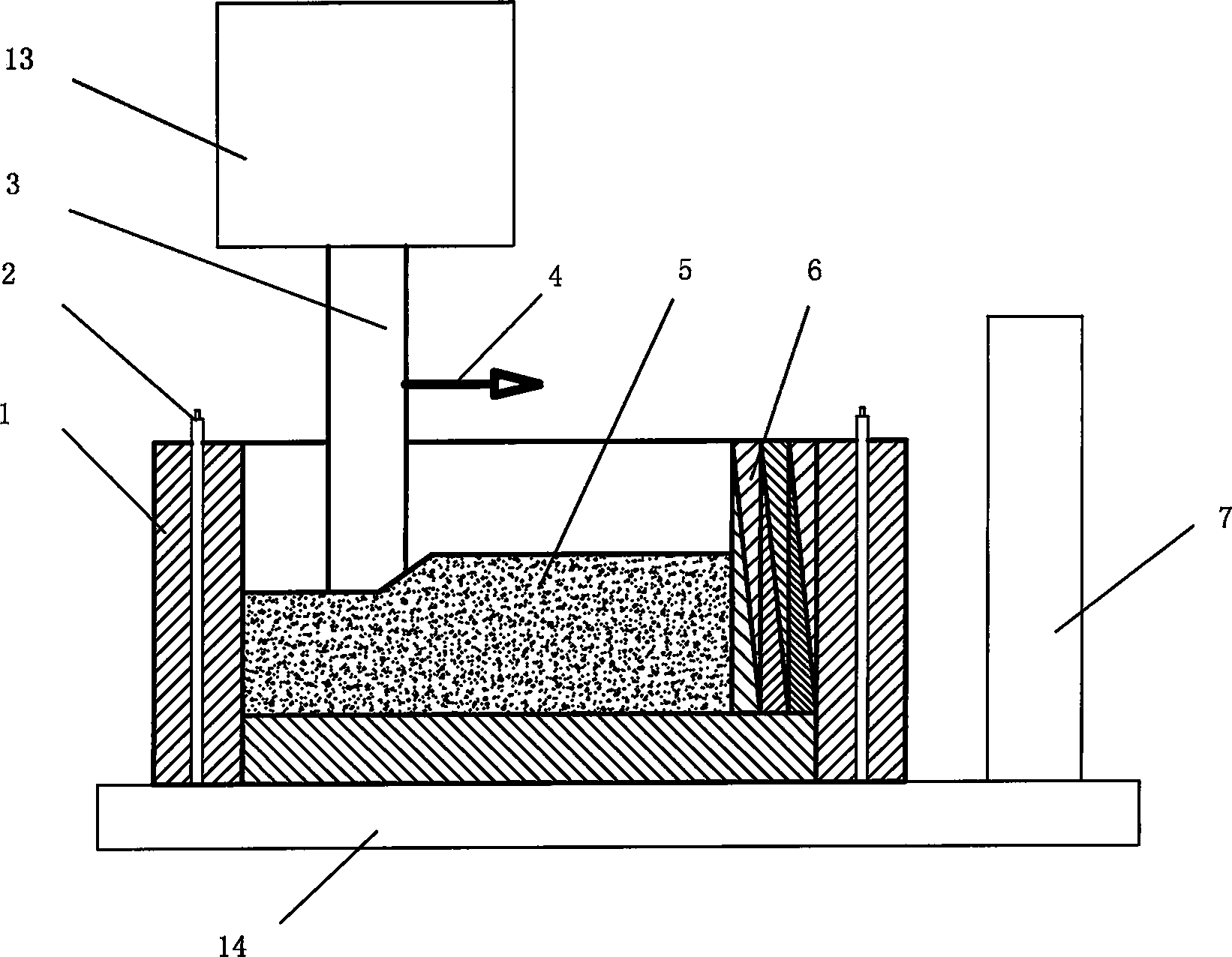

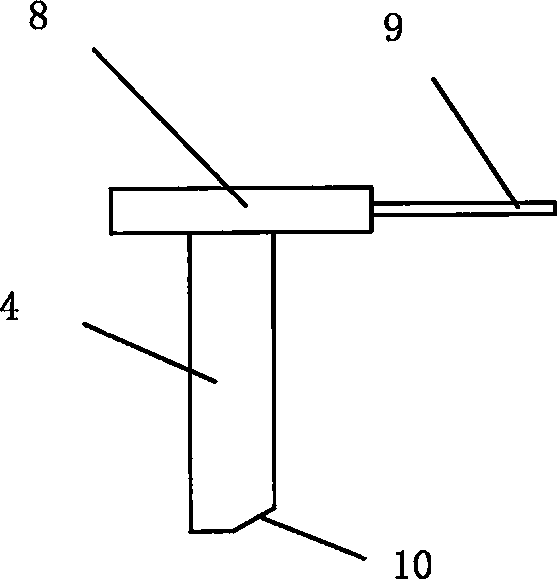

[0022] see figure 1 and figure 2 , a square combination mold 1 is installed on the press workbench 14, a movable combination module 6 is arranged in the square combination mold 1, a step-by-step propulsion device 9 is provided on the top of the press head 13, and the step-by-step propulsion device 9 is provided with a slide plate 8, and a wedge-shaped indenter 3 is arranged on the slide plate 8. A small part of the end surface of the wedge-shaped indenter 3 is a plane 12 and the rest is an inclined surface 10. 7 degrees, preferably 5 degrees. In order to determine the single reduction and transverse shear value, a limit device 7 corresponding to the press head 13 is provided on the press table 14 .

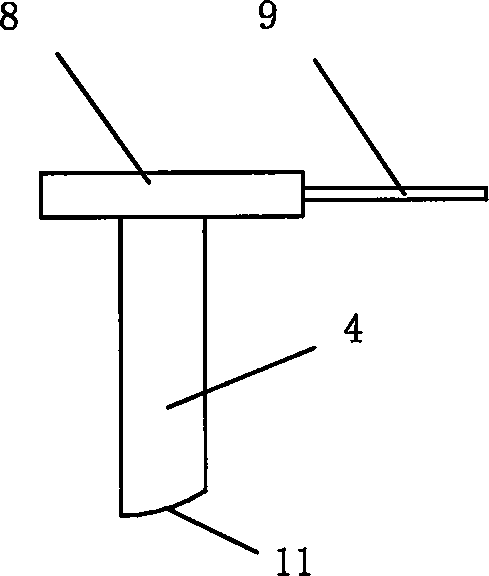

[0023] see figure 1 and image 3 , The end face of the wedge-shaped punch 3 can also be designed as an arc 11.

[0024] The present invention is described in further detail below in conjunction with embodiment.

[0025] Laterally deformed wedge pressing was performed using a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com