Construction method for lay down coil pipe openly under structure plates of sunshade

A construction method and technology of structural panels, applied in the direction of pipeline supports, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve problems affecting structural safety and service life, difficult to guarantee quality, expensive engineering cost, etc., and achieve easy construction quality , Save engineering cost, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

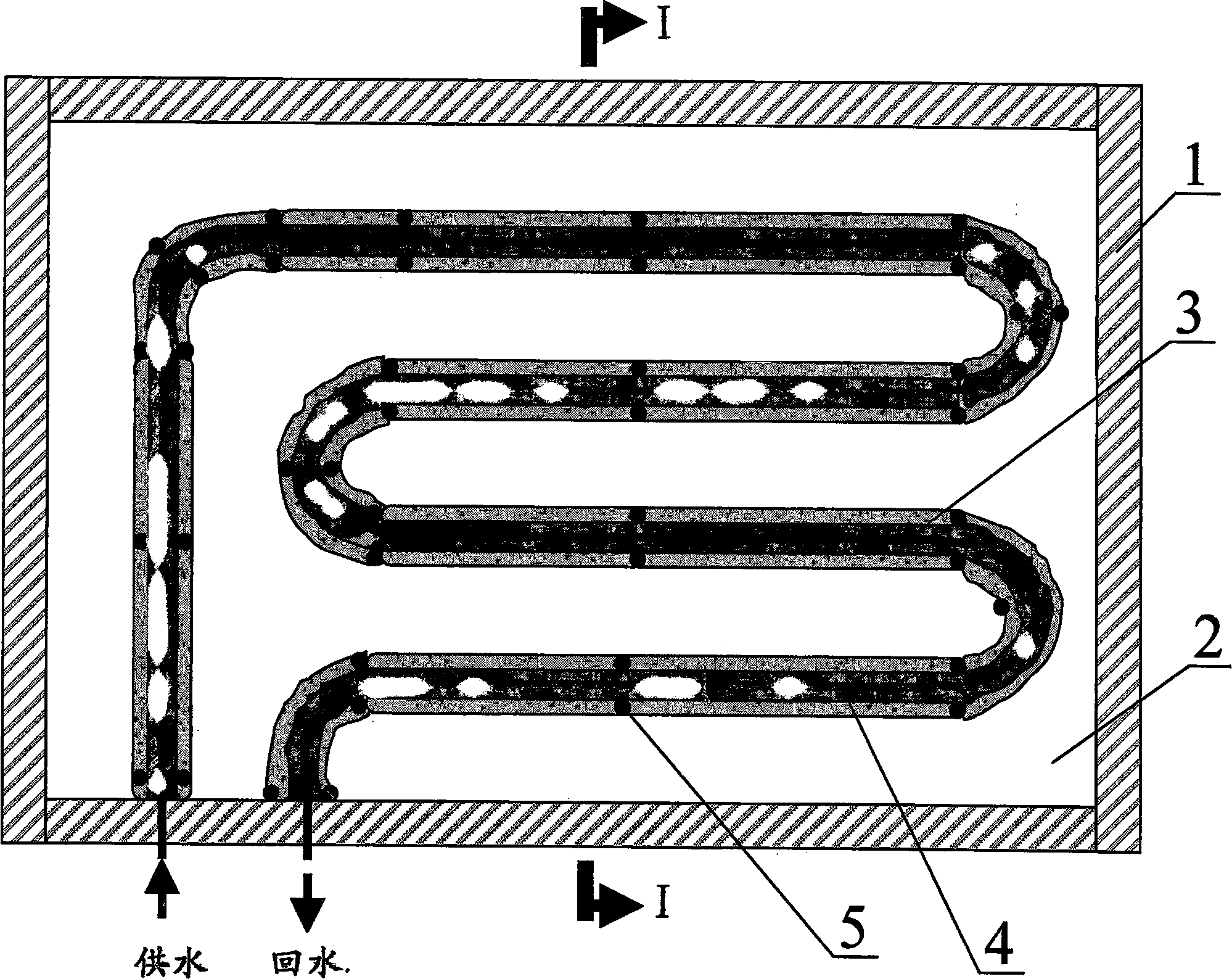

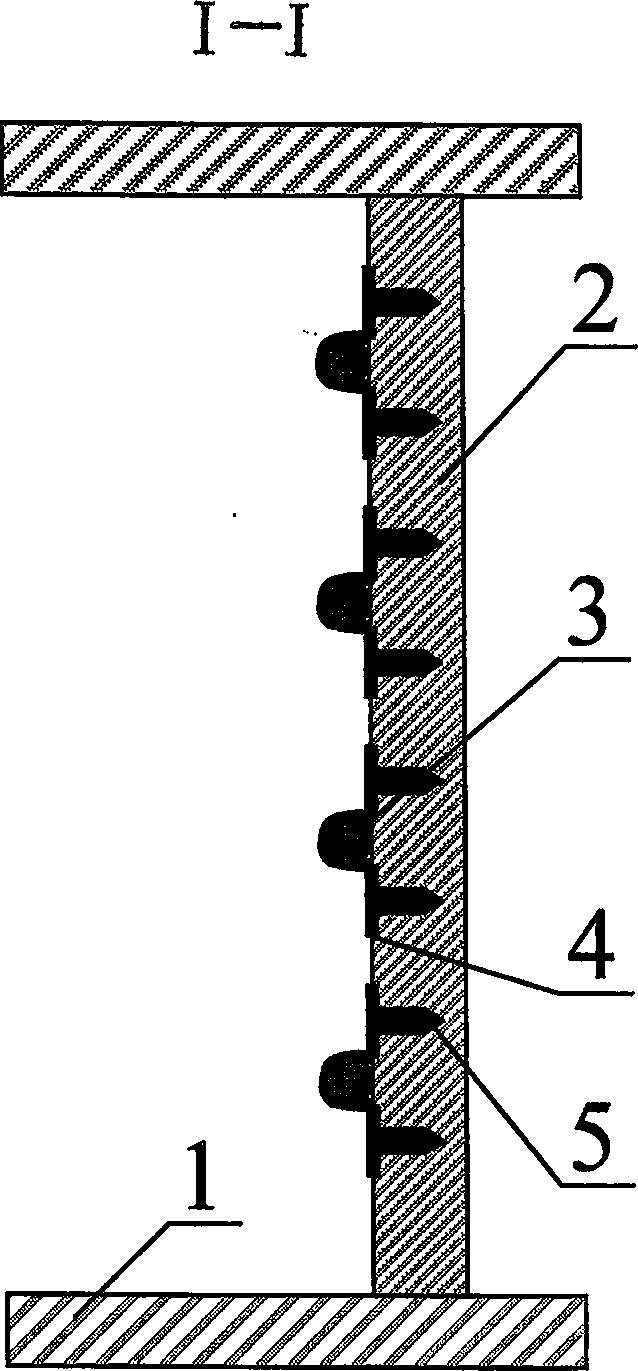

[0010] Such as Figure 1-2 As shown, a construction method for laying open coils under the ceiling structural slab, which is to install the coils 3 used for low-temperature radiant heating and cooling under the reinforced concrete structure floor after the construction of the building structure is completed. The construction method is as follows: First, insert the coil 3 with an outer diameter of 14mm-22mm into the slot 4 of the metal sheet metal processing part with a thickness of 0.6mm-1.0mm, a width of 60mm-100mm and a length of 600mm-1000mm, and then insert the metal sheet The metal processing part 4 is fixed under the structural floor 2 supported by the structural wall or the non-load-bearing lightweight partition wall 1 with expansion screws 5 and structural glue. Among the above, the coiled tube 3 can be metal tube, alloy tube, plastic tube or o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com