Mems switch

A switch and conductive layer technology, applied in the field of MEMS switches, can solve the problems of high driving voltage, low operating speed, and insufficient reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

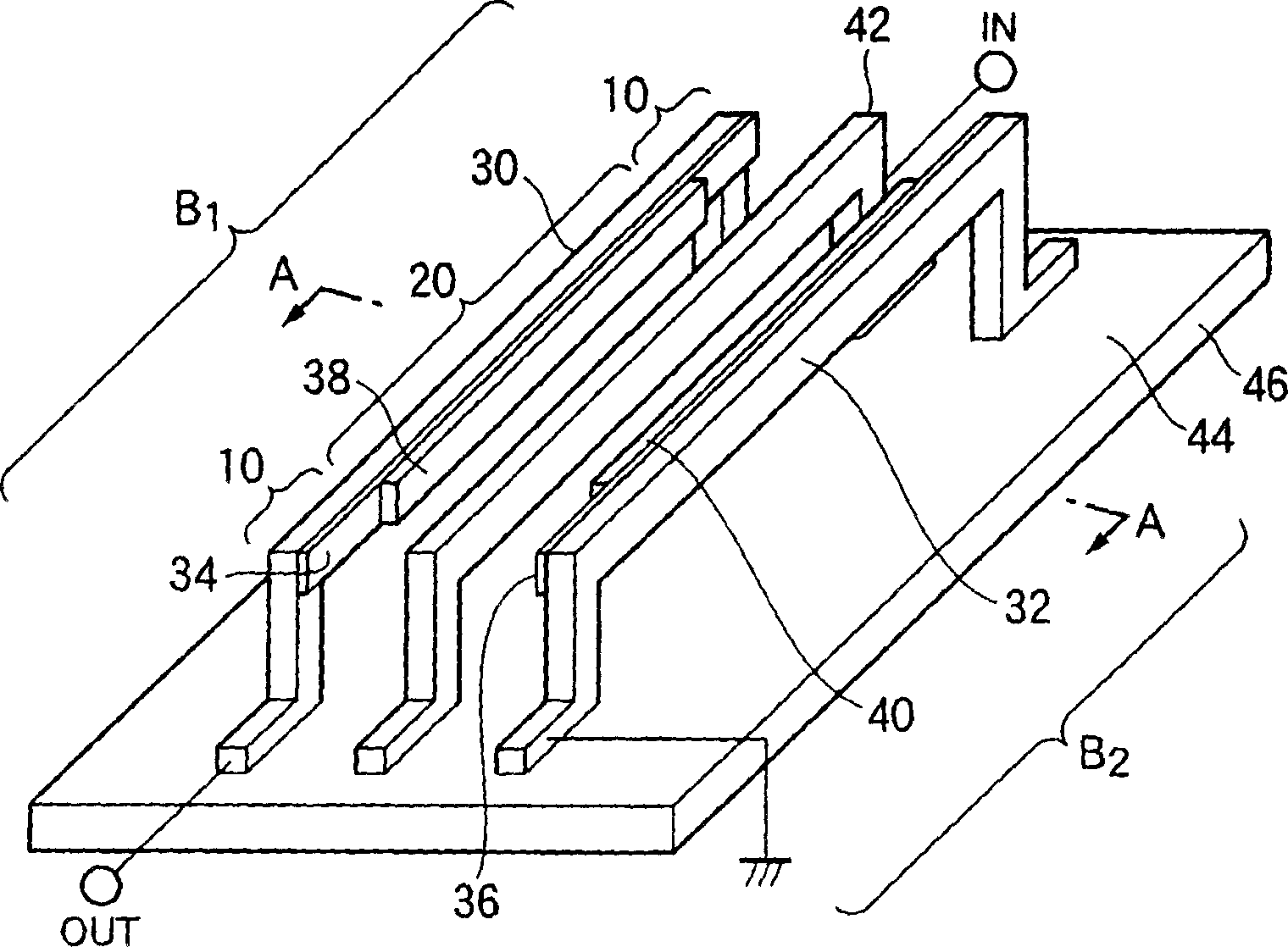

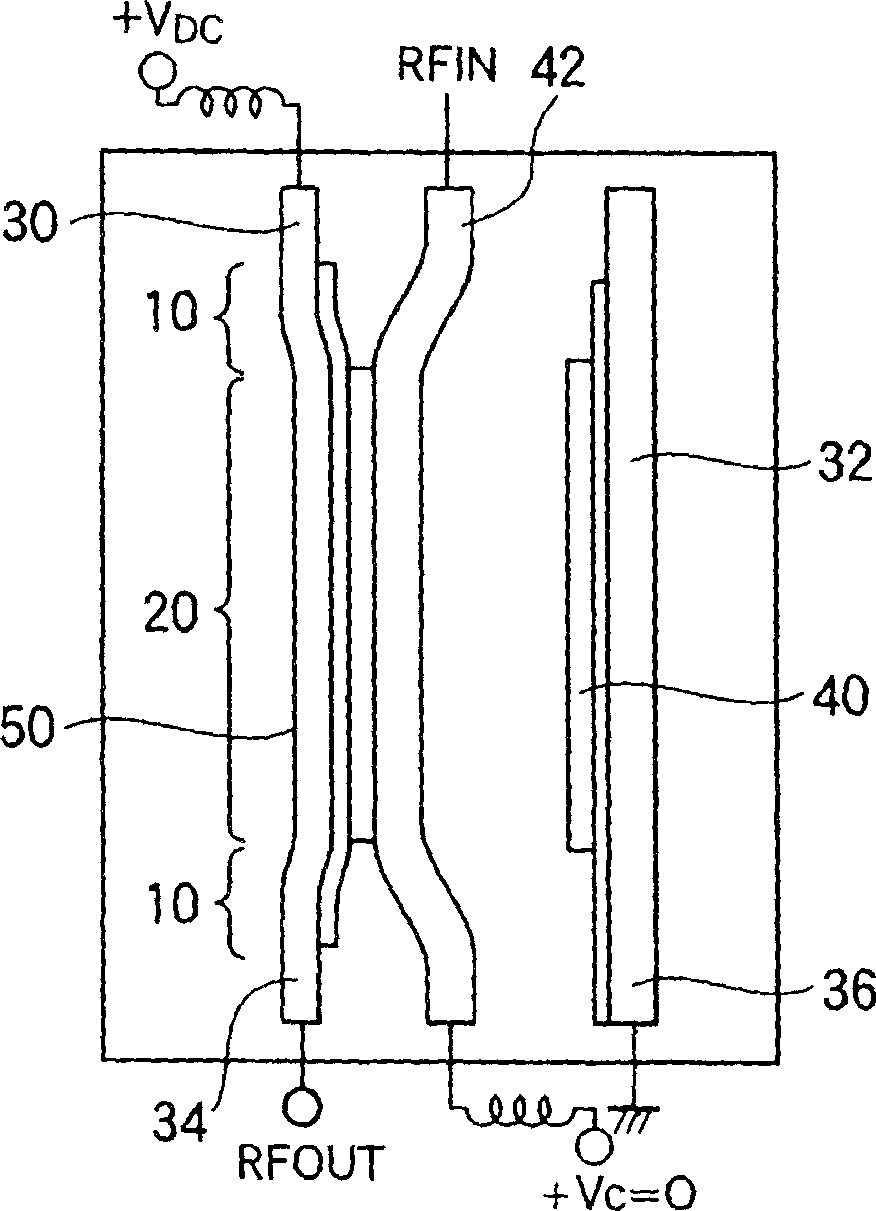

[0110] The MEMS switch is formed by processing the silicon substrate 1 with MEMS technology. like figure 1 As shown, the MEMS is formed such that air bridges are disposed in the surface of the silicon substrate 46 . The MEMS switch is formed by a conductive beam 42 and first and second three-layer structure beams B1 and B2 each having a capacitive structure. The conductive beam 42 and the three-layer structure beam B1 are respectively connected to the input terminal and the output terminal, and the three-layer structure beam B2 is also grounded. Each of these first and second three-layer structural beams is formed by sandwiching a dielectric layer between a first conductive layer 38 , 40 and a second conductive layer 30 , 32 . Then, the first and second three-layer structure beams B1 and B2 having the conductive beam 42 interposed therebetween are displaced on a plane parallel to the substrate due to electrostatic force, so that the conductive beam 42 and the first conductiv...

Embodiment 2

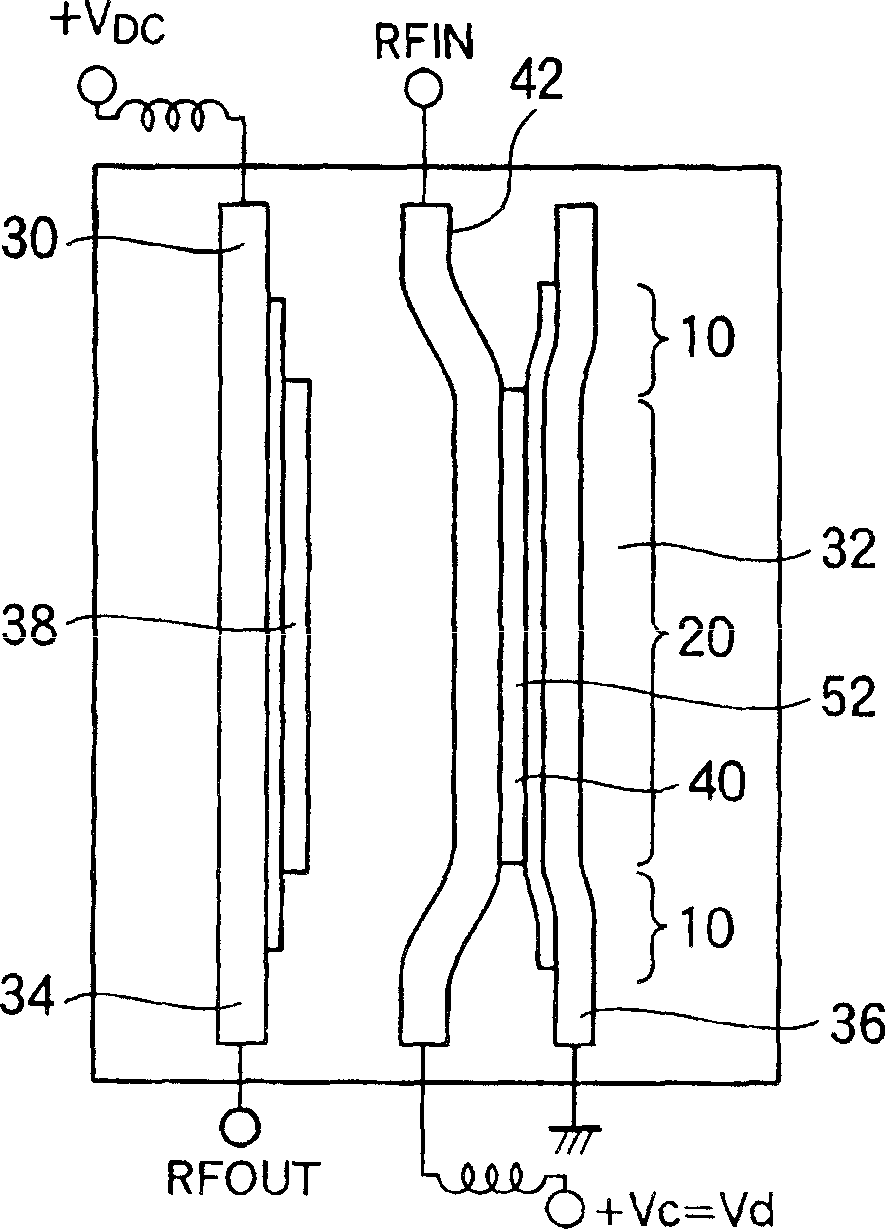

[0145] The driving method and basic configuration of the MEMS switch according to this embodiment 2 are similar to those in embodiment 1. All beams were formed as arched beams in Example 1. However, if Figure 10 As shown, the MEMS switch according to Embodiment 2 is characterized in that the centrally located conductive beam 42 is formed to have a cantilever beam structure slightly shorter than the arched beam. That is, if Figure 10 As shown, the MEMS switch is characterized in that the conductive beam 42 is fabricated to be half the length of any other beam, ie 250 μm.

[0146] The MEMS switch according to this embodiment differs from the MEMS switch according to Embodiment 1 in that the second conductive layer forming the second three-layer structural beam is not grounded but connected to the second output terminal.

[0147] With this configuration, when the conductive beam 42 is adjacent to the first three-layer structural beam and the second three-layer structural bea...

Embodiment 3

[0160] According to this example, as Figure 12 As shown, protruding portions serving as capacitive regions 84 and drive surfaces 86 are formed in the surfaces of the second conductive layers 30 and 32 . Figure 12 shows the as-of status. In the conducting state, the conductive beam 42 adjoins the metal-to-metal contact surface 82 of each capacitive region, resulting in electrical coupling.

[0161] Next, the coupling state in the on state will be explained. Figure 14 is an enlarged view showing the contact surface in the conduction state. A state is shown in which the conductive beam 42 is adjacent to the first conductive layer (first electrode) 38 of the first three-layer structure beam. When the conductive beam 42 and the metal-metal contact surface 82 move to abut each other due to electrostatic force, the potential of the first conductive layer 38 forming the first three-layer structure beam becomes equal to the potential of the conductive beam 42 . Thus, a capacitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com