Horizontally wire-feeding split type micro electric spark wire cutting device

A technology of EDM wire and cutting device, applied in electrode manufacturing, electric processing equipment, metal processing equipment, etc., to achieve the effect of convenient installation and adjustment, improved processing accuracy and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

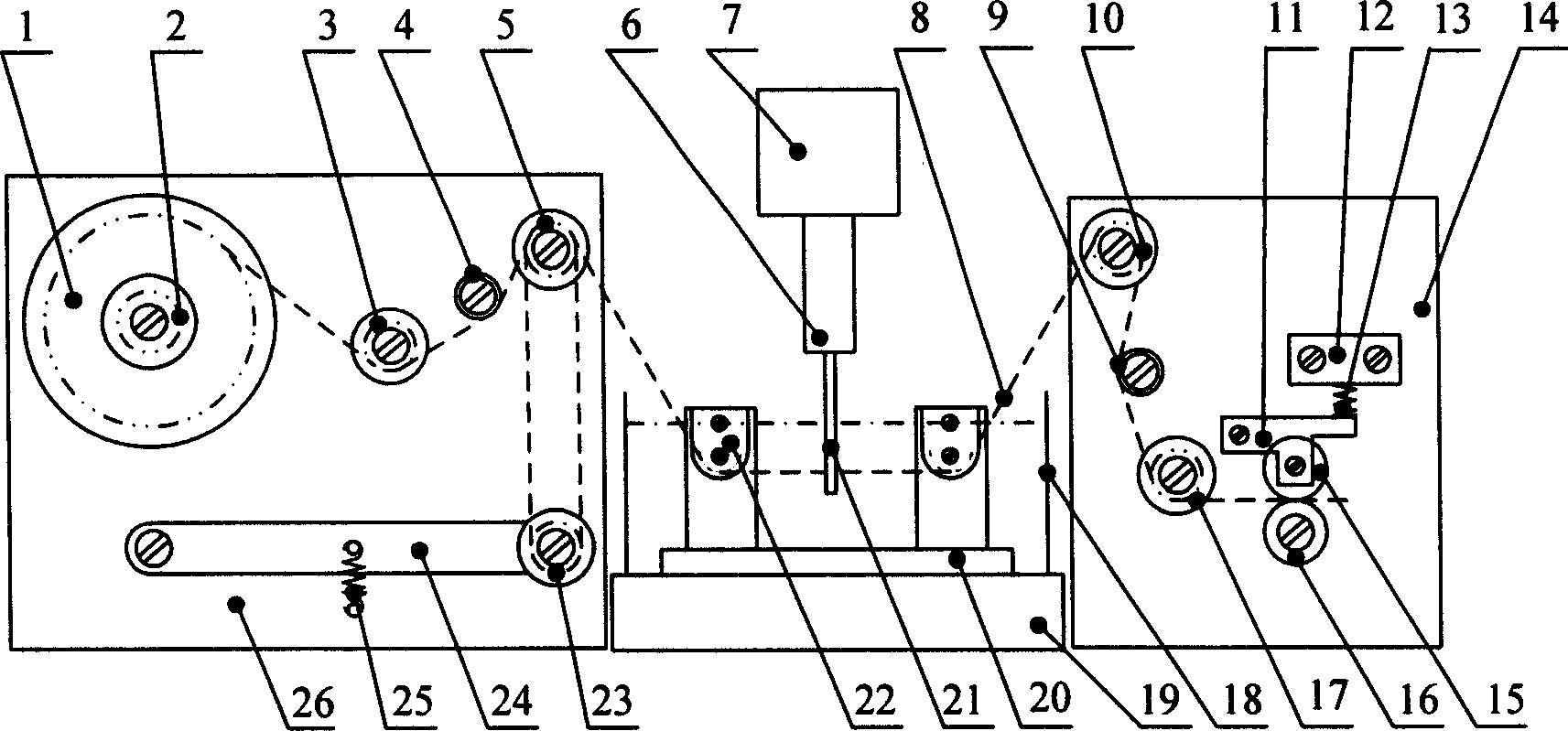

[0015] As shown in the figure, the present invention is composed of three parts: a tension control device, a wire running device and a wire receiving device.

[0016] 1. Tension control device

[0017] The tension control device consists of a wire storage drum 1, a compression spring 2, the first single-filament track fixed guide wheel 3, the first felt ring 4, double-filament track fixed guide wheels 5, single-filament track floating guide wheels 23, a lever 24, and a tension spring 25 and tension control device carrier 26 composition. The wire storage drum 1, the compression spring 2, the first monofilament fixed track guide wheel 3, the first felt ring 4, the double thread track fixed guide wheel 5, and the fixed end of the lever 24 (the left end in the figure) are all fixed by screws at tension. On the control device carrier 26, except the first felt ring 4, all can rotate around the screw; the single wire track floating guide wheel 23 is fixed on the movable end (the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com