Ceramic heat exchanger, composite ceramic material and production method thereof

A technology of ceramic materials and production methods, applied in the field of refractory materials and heat exchangers, can solve the problems of lowering the temperature recovered by the heat exchanger, cannot be used directly, and low energy utilization rate, and achieves fuel saving, strong applicability, and production. Method Mature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one: ceramic material and production method thereof

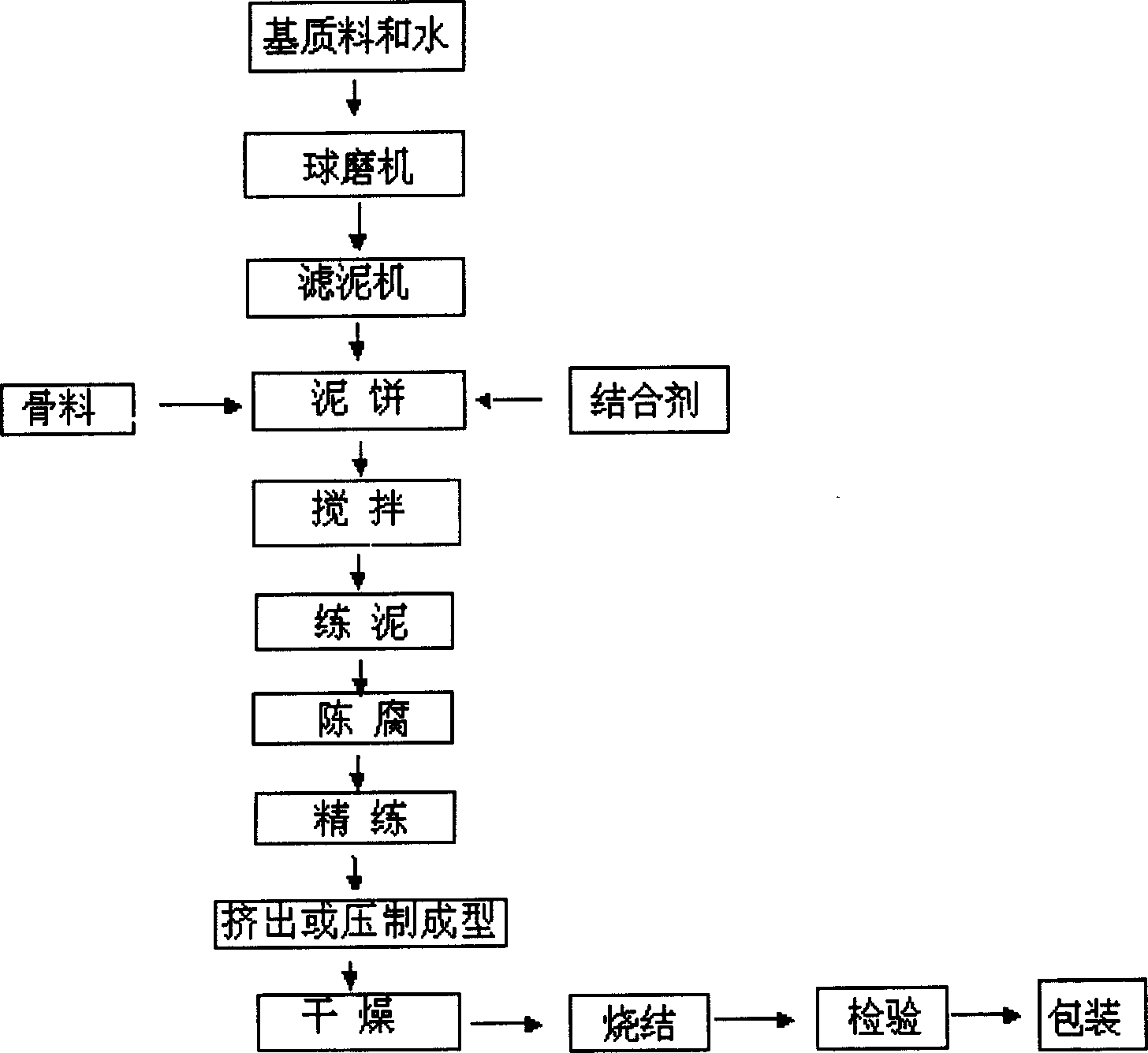

[0045] Its production process steps include raw material selection and preparation, ball milling, filtration, mixing, mud refining, aging, scouring, extrusion molding, drying, sintering, finished product inspection, assembly and storage. The detailed steps are:

[0046] 1. Weigh mullite powder, cordierite powder, talc powder, clay powder, α-Al 2 o 3 As base material component A, the weight percentages of various components in the base material are: mullite powder 20%, cordierite powder 40%, talc powder 10%, clay powder 10%, α-Al 2 o 3 20%;

[0047] Weigh mullite and cordierite as aggregate component B, the weight percentage of these two components in the aggregate is 16% for mullite with a particle size of 0-0.5mm, and 36% for mullite with a particle size of 0.5-1mm. %, cordierite with a particle size of 0-0.5mm is 34%, and cordierite with a particle size of 0.5-1mm is 14%. The weight ratio of the two...

Embodiment 2

[0056] Embodiment two: ceramic material and production method thereof are basically the same as embodiment one, and the similarity is no longer described, and the difference is:

[0057] 1. Base material component A, mullite powder 40%, cordierite powder 20%, talc powder 20%, clay powder 10%, α-Al 2 o 3 The particle size of 10% base material is 220 mesh.

[0058] In the aggregate component B, mullite with a particle size of 0-0.5mm is 36%, mullite with a particle size of 0.5-1mm is 16%, cordierite with a particle size of 0-0.5mm is 14%, cordierite with a particle size of 0.5-1mm was 34%. The weight ratio of the two components A and B is 1:1, and then add 1% of the binder accounting for the total weight of the two components A and B.

[0059] 2. Measure and weigh according to the formula of the base material, add water (the weight ratio of water to the base material is 1:3), send it into a wet ball mill for grinding for 10-12 hours, and the particle size after grinding is 3...

Embodiment 3

[0062] Embodiment three: ceramic material and production method thereof are basically the same as embodiment one, and the similarity is no longer described, and the difference is:

[0063] 1. Base material component A: mullite powder 25%, cordierite powder 25%, talc powder 30%, clay powder 10%, α-Al 2 o 3 10%;

[0064] In the aggregate component B, the mullite with a particle size of 0-0.5mm is 20%, the mullite with a particle size of 0.5-1mm is 20%, the cordierite with a particle size of 0-0.5mm is 30%, and the cordierite with a particle size of 0.5-1mm is 30%.

[0065] The weight ratio of the two components A and B is 1:1.5, and then add 0.8% of a binder accounting for the total weight of the two components A and B.

[0066] 2. During sintering, the temperature is controlled at 1350°C, sintered for 40 hours according to the usual shelf life, kept for 5 hours, cooled to below 500°C and released from the furnace.

[0067] Sintering temperature rise requirements, the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com