Heat conductive caulking pad with composite structure

A composite structure and gasket technology, used in semiconductor devices, cooling/ventilation/heating transformation, semiconductor/solid-state device components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

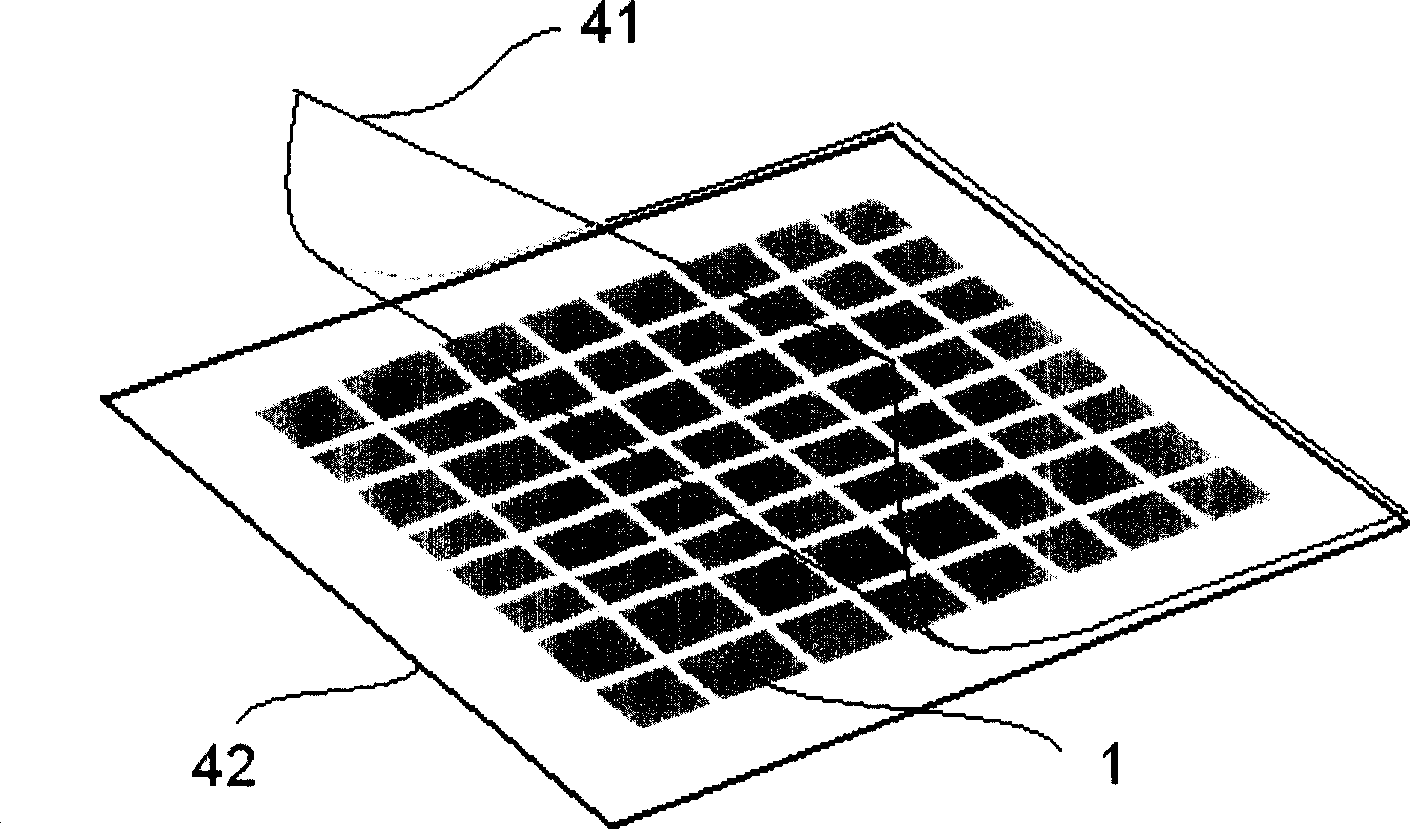

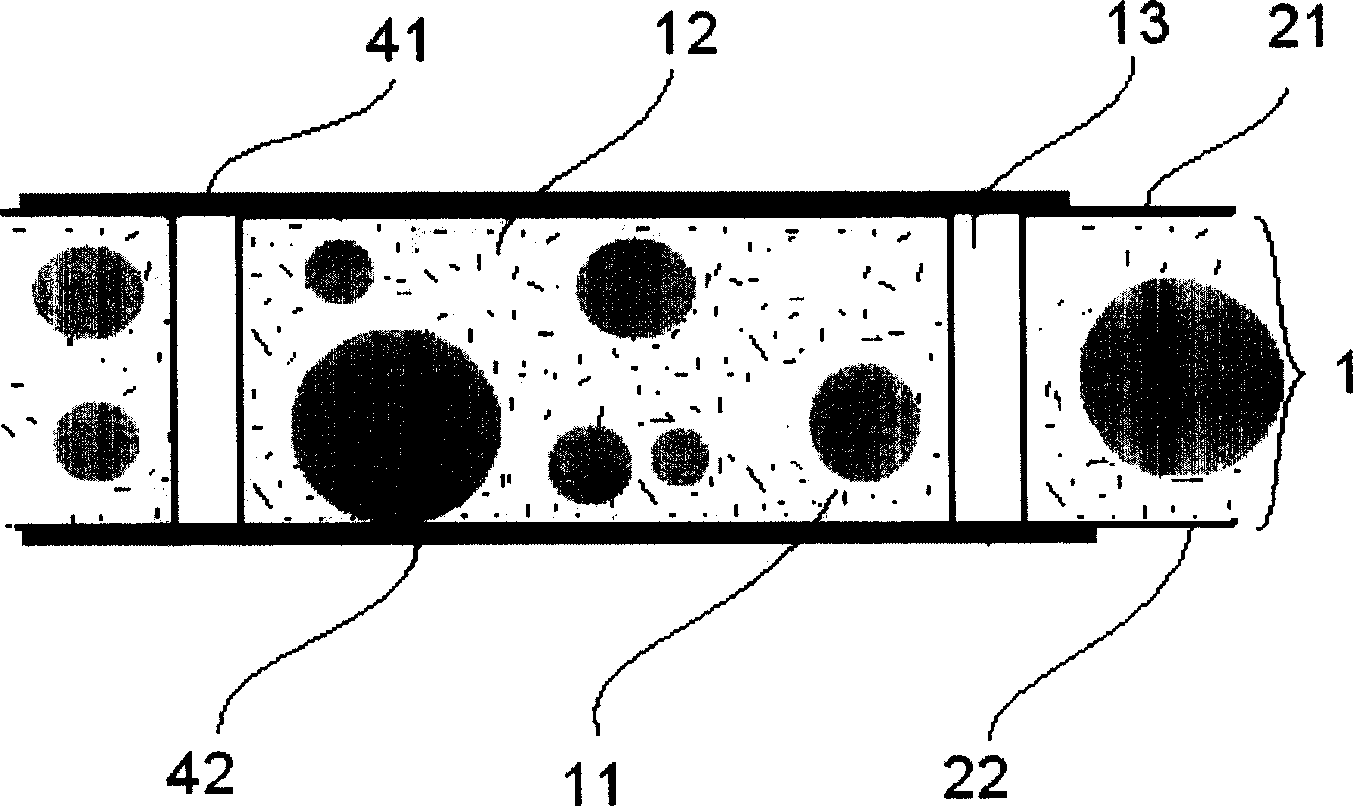

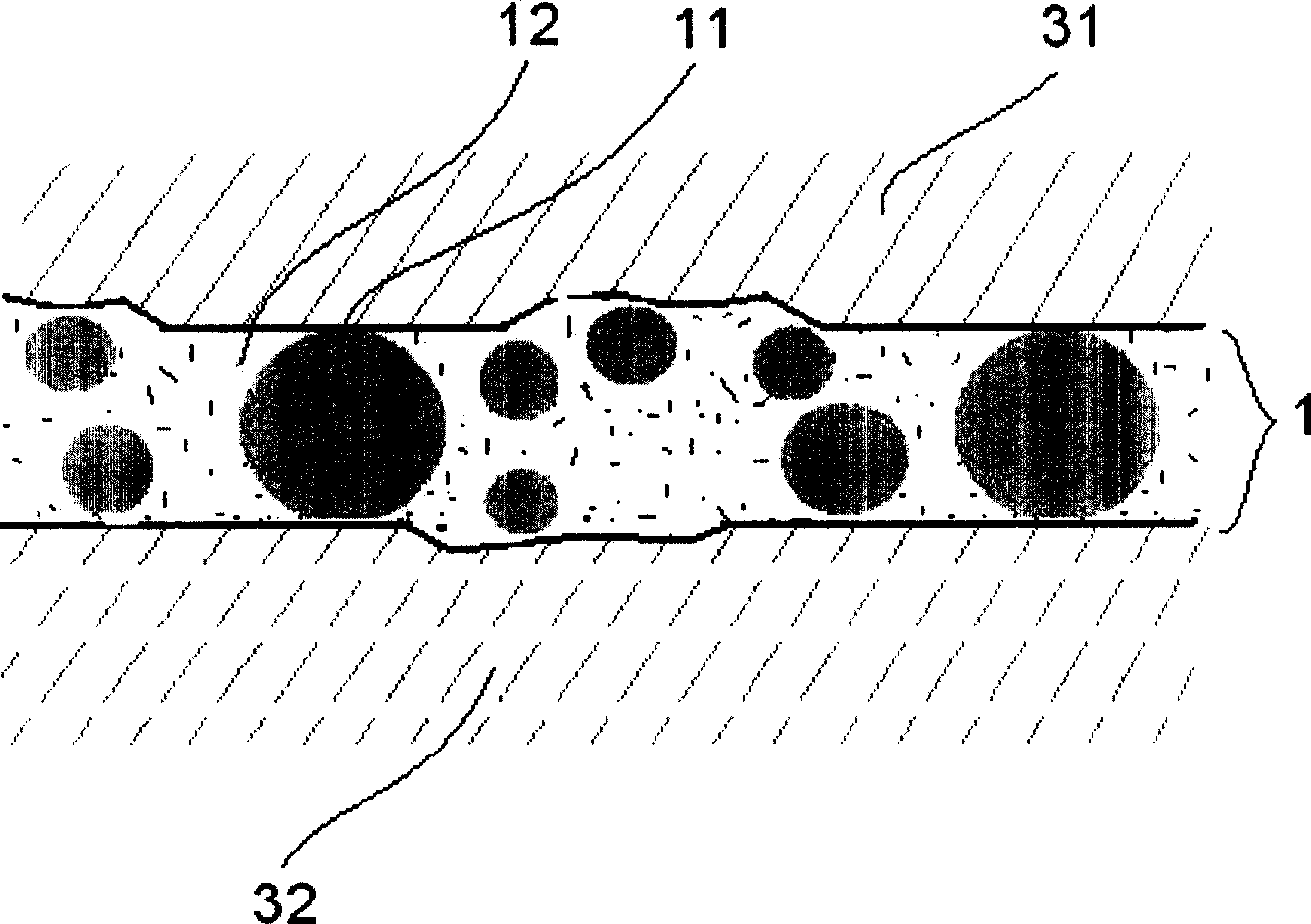

[0027] Embodiment of the soft heat conduction layer with checkerboard distribution of exhaust channels, such as Figure 4 shown. According to the roughness tolerance of the contact surface of the heating element and the heat dissipation element, the particles 11 with a specific size are mixed with the fluid plastic polymer material 12 to form a soft heat conduction layer 1 with a checkerboard-like distribution of exhaust channels. Both sides of the soft heat conduction layer are covered with release film protection. After tearing off the release film on the first side during use, attach this side of the soft heat conduction layer to the contact surface of the heating element or the contact surface of the heat dissipation element, and then Tear off the release film on the second surface, and press the heat conduction layer to the remaining contact surface of another component. When the soft heat-conducting layer is placed between the heating element and the heat-dissipating el...

Embodiment 2

[0029] Examples of soft heat conduction layer for radially distributed exhaust passages, such as Figure 5 shown. According to the roughness tolerance of the contact surface of the heating element and the heat dissipation element, the particles 11 with a specific size are mixed with the fluid plastic polymer material 12 to form a soft heat conduction layer 1 with a checkerboard-like distribution of exhaust channels. The first side of the flexible heat conduction layer may not use the release film 41 on the first side, but directly use the screen printing method to place the structural material on the heat dissipation end surface in advance, and then cover the second side with a release paper for protection. When in use, the release film on the second surface is torn off, and pressed together with the remaining contact surface of another component. When the soft heat conduction layer is placed between the heating element and the heat dissipation element and is squeezed, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com