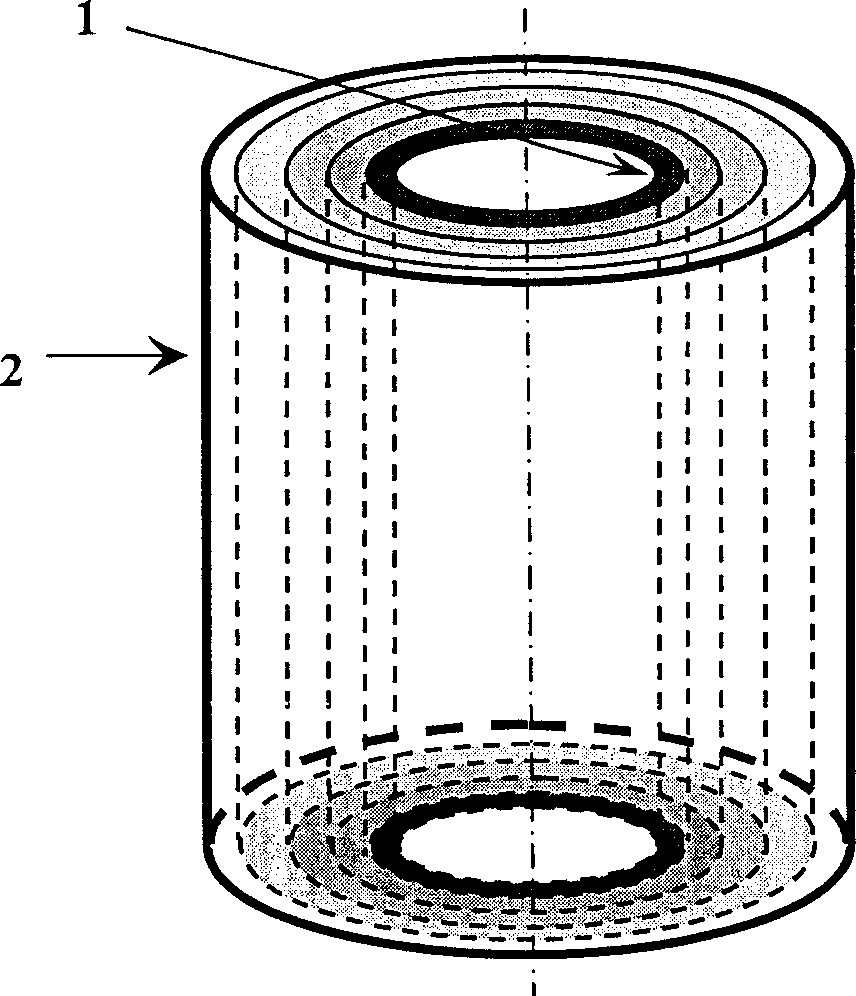

Radial gradient ceramic blast nozzle

A technique of radial gradient, sandblasting nozzles, applied in the direction of spray guns, manufacturing tools, abrasives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Taking SiC as the matrix, weighing the raw materials according to the content of solid solution (W, Ti)C respectively: 20%, 35%, and 50% by mass, and configuring 3 kinds of SiC+( with different (W, Ti)C content W, Ti) C ceramic composite powder; then separately strengthened ball milling, using ethanol as the medium, the ball milling time is 200 hours; the ball milled SiC+(W, Ti) C ceramic composite powder is placed in a vacuum drying oven to dry, after drying, in Sieving in a cabinet with a nitrogen atmosphere; 3 kinds of dried SiC+(W,Ti)C ceramic composite powders with different contents of (W,Ti)C are respectively loaded into graphite molds, according to (W,Ti)C The content of solid solution gradually increases from the surface of the inner hole of the blast nozzle to the outer wall of the blast nozzle, and the graphite mold is charged in the order. Nitrogen is used as the sintering atmosphere, and a hot-press sintering process is used to prepare a radial 3-lay...

Embodiment 2

[0017] Example 2: As described in Example 1, the difference is that 4 types of (W, Ti) C content are configured as follows: 20%, 30%, 40%, 50% SiC+(W, Ti)C ceramic composite powder . The hot-pressing sintering process is used to prepare radial 4-layer gradient ceramic sandblasting nozzles. The sintering temperature is 1950°C, the pressure is 30 MPa, and the holding time is 50 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com