Lead zirconate titanate/silicon carbide composite ceramic materials and method for preparing same

A technology of lead zirconate titanate and composite ceramics, which is applied in the field of ferroelectric materials, can solve the problems affecting the sintering performance of the porcelain body and the difficulty of compacting the porcelain body, so as to improve the mechanical properties and electric breakdown strength, and increase the insulation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

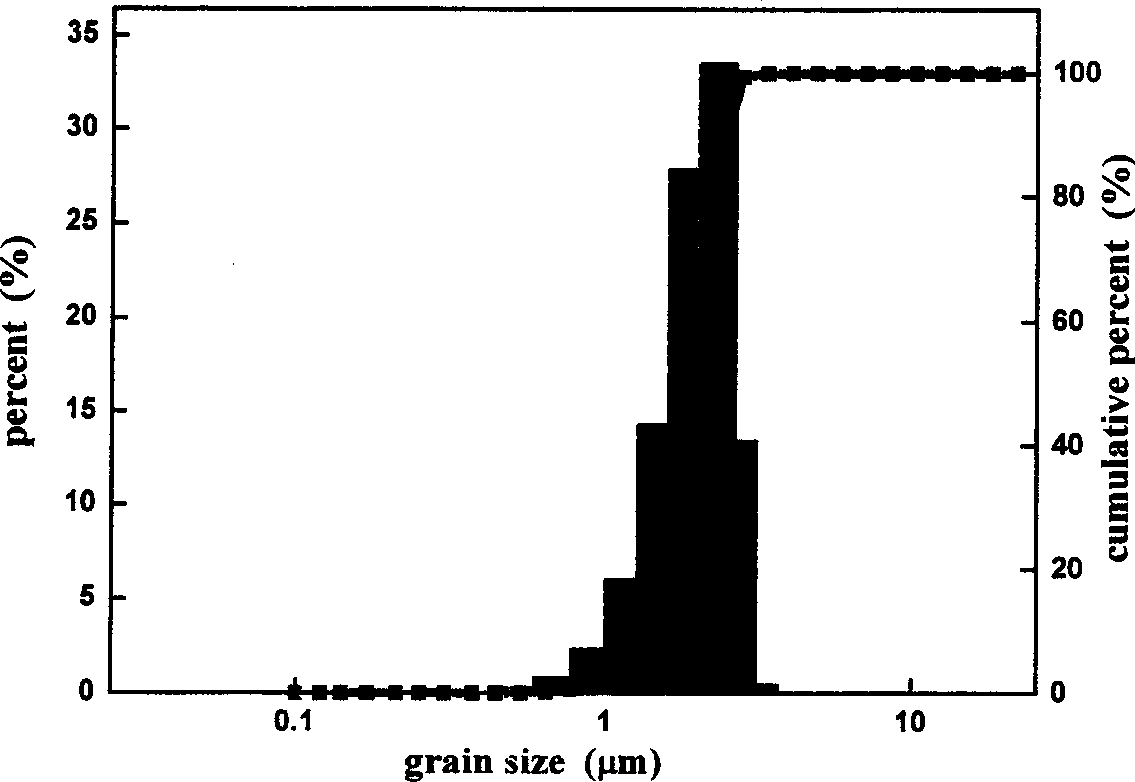

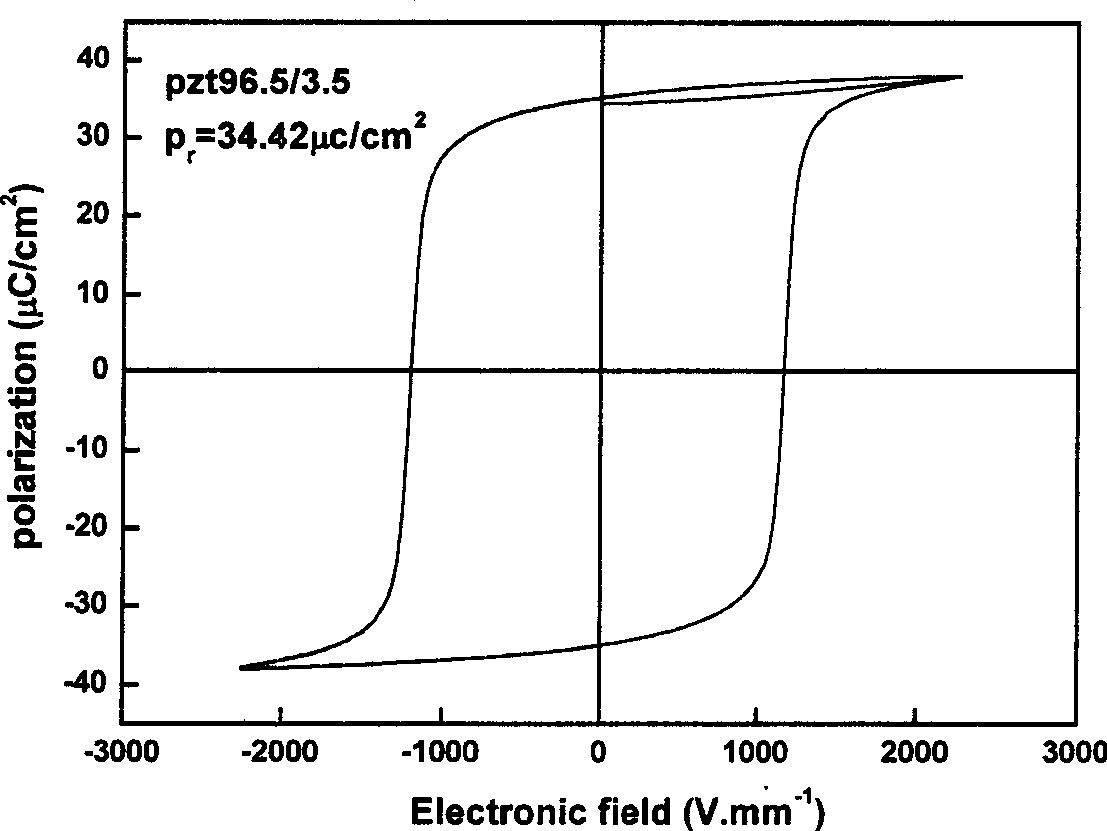

[0031] Pb in powder form 3 o 4 , ZrO 2 ,TiO 2 , Nb 2 o 5 and SiC powder with an average particle size of 2 μm as raw materials, according to the stoichiometric ratio of Pb(Zr 0.965 Ti 0.035 )O 3 +1wt.%Nb 2 o 5 preparation. After wet ball milling for 8 hours, the material was discharged, dried, and the powder was pre-calcined at 850°C for 2 hours to obtain Pb(Zr 0.965 Ti 0.035 )O 3 +1wt.%Nb 2 o 5 Powder. The powder is then wet ball milled for 24 hours, discharged, dried, added 6wt.% PVA to granulate, and pressed to shape the powder under a pressure of 150Mpa; debinding at 800°C / 2h, and sintered at 1300°C / 2h. The fired samples are finely ground to obtain matrix ceramic samples. After the surface of the base ceramic sample is finely ground and ultrasonically cleaned, the sample is embedded in SiC micropowder, heat-treated at 850°C for 2 hours, and then the parallel surface is finely ground to about 0.2mm, and then it is burnt by silver electrodes and high-temperat...

Embodiment 2

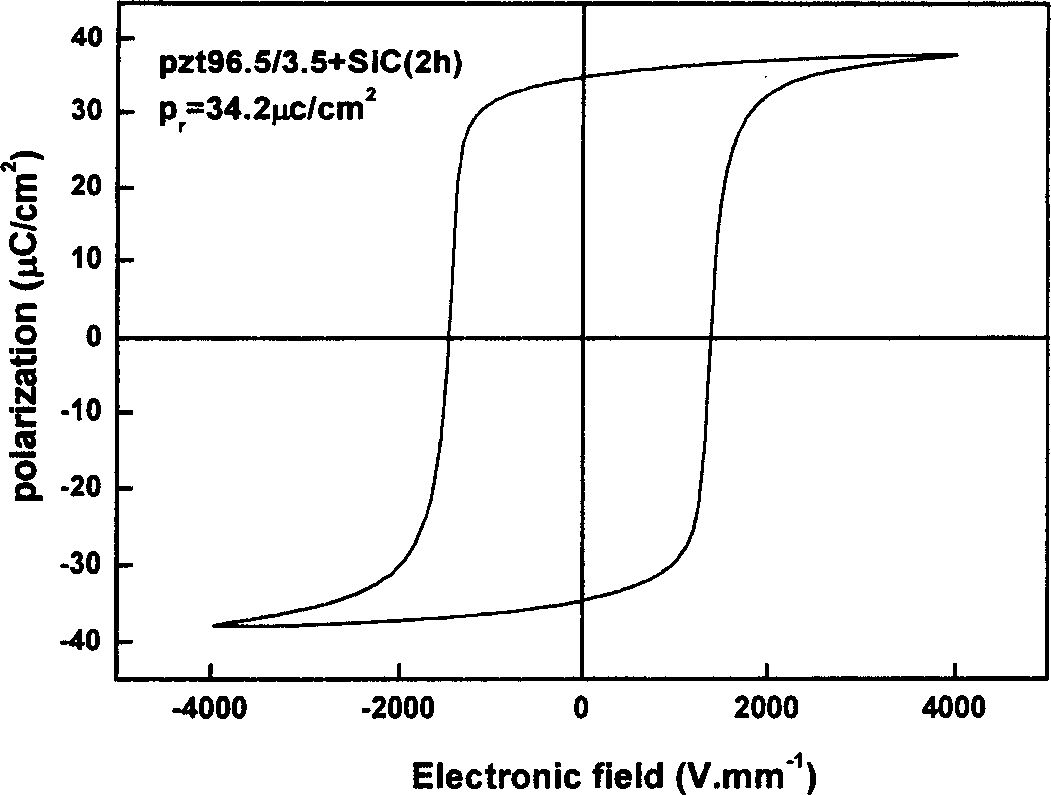

[0033] Pb in powder form 3 o 4 , ZrO 2 ,TiO 2 , Nb 2 o 5 and SiC powder with an average particle size of 2 μm as raw materials, according to the stoichiometric ratio of Pb(Zr 0.965 Ti0.035 )O 3 +1wt.%Nb 2 o 5 preparation. After wet ball milling for 8 hours, the material was discharged, dried, and the powder was pre-calcined at 850°C for 2 hours to obtain Pb(Zr 0.965 Ti 0.035 )O 3 +1wt.%Nb 2 o 5 Powder. The powder was then wet ball milled for 24 hours, discharged, dried, added 6wt.% PVA to granulate, and pressed to form the powder under a pressure of 150Mpa; debinding at 800°C / 2h, and sintered at 1300°C / 2h. The fired samples are finely ground to obtain matrix ceramic samples. After the surface of the base ceramic sample is finely ground and ultrasonically cleaned, the sample is embedded in SiC micropowder, heat-treated at 850°C for 4 hours, and then the parallel surface is finely ground to about 0.2mm, and then it is fired by silver electrode and high temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com