Al-Li composite anode oxide film preparation method

A composite anode, anodizing technology, applied in anodizing, superimposed layer plating, coating, etc., can solve the problems of high price and complicated manufacturing, and achieve high corrosion resistance, high AC impedance value, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

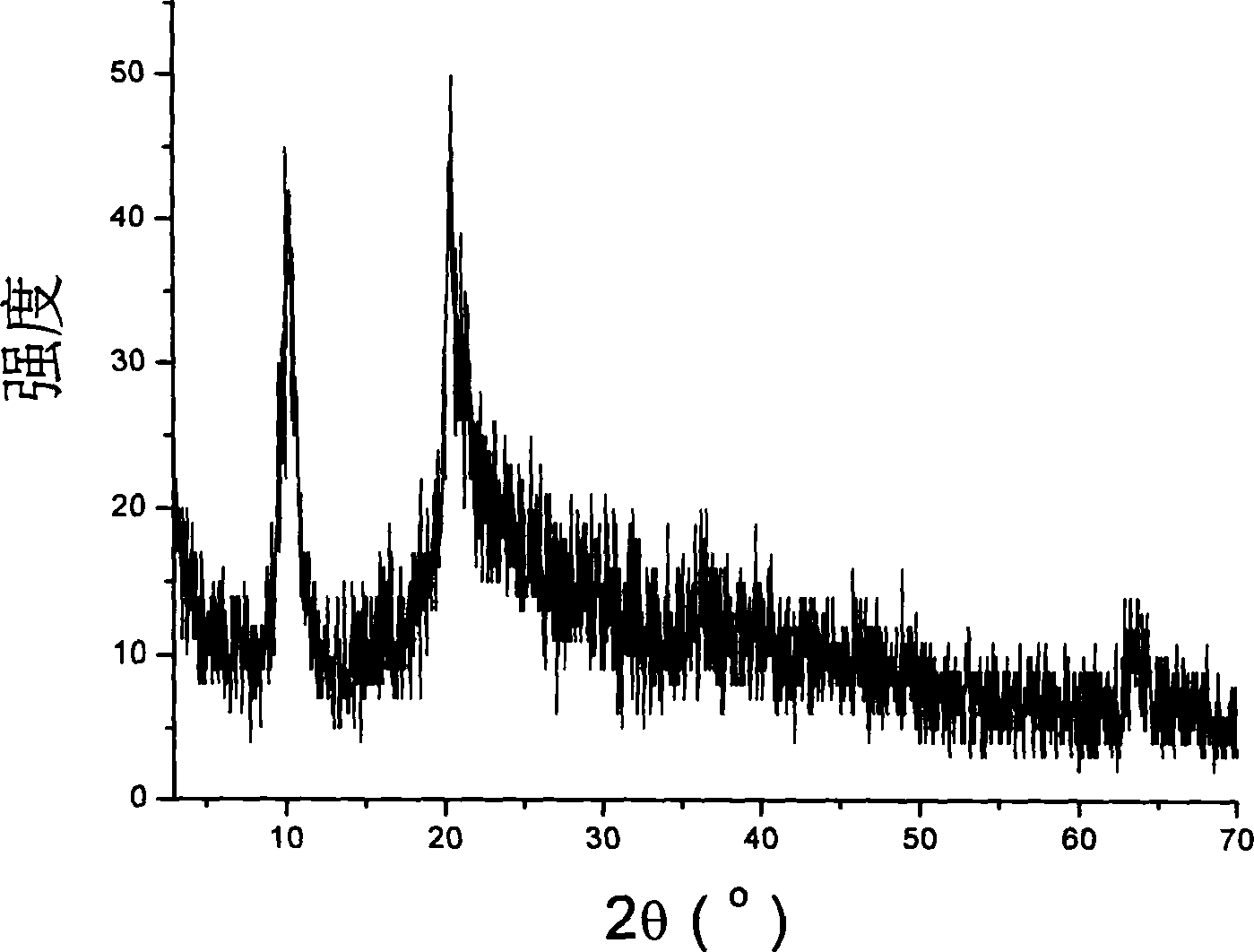

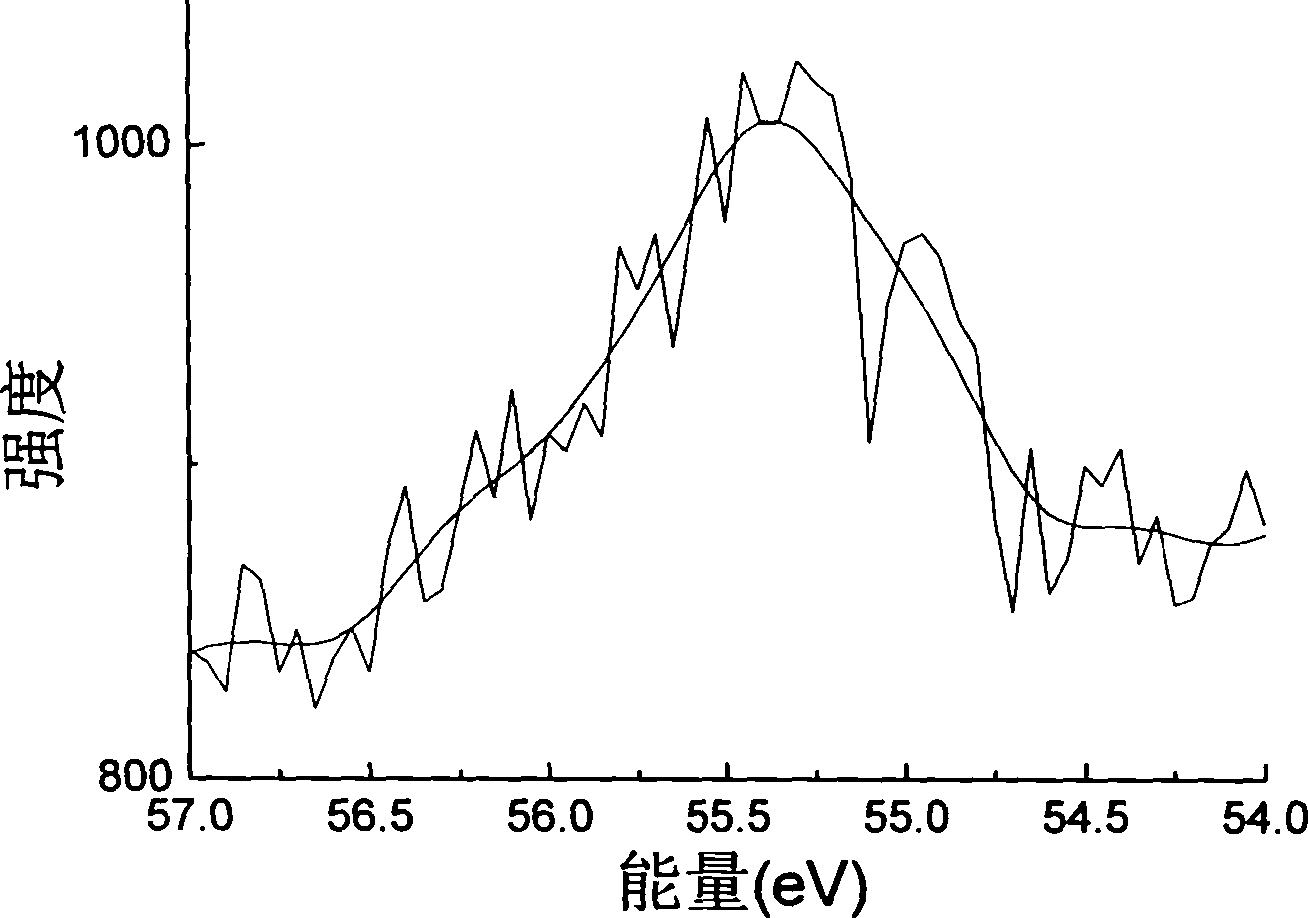

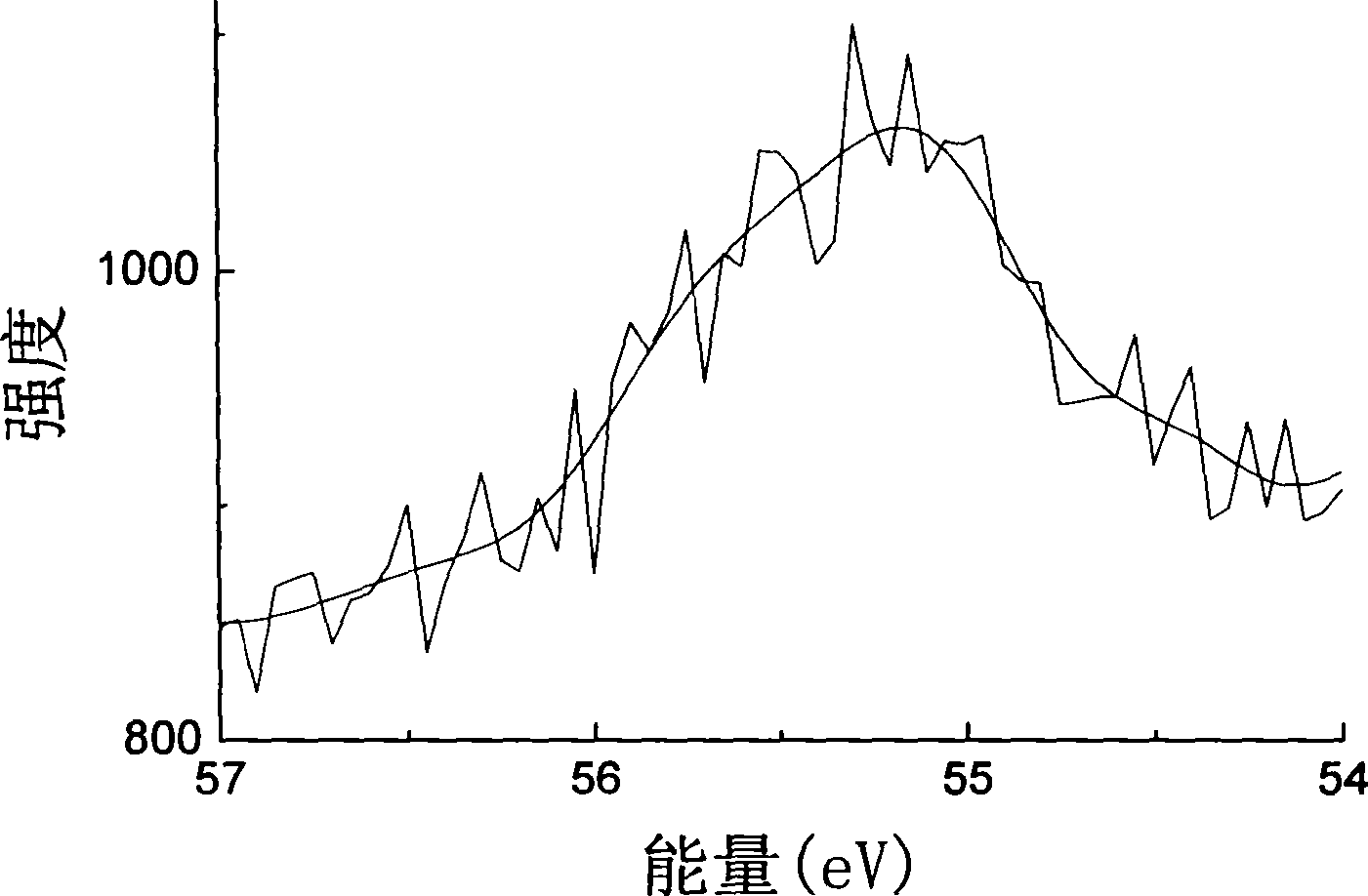

Image

Examples

Embodiment 1

[0021] Example 1 Preparation of Al-Li Composite Anodic Oxidation Film by High Purity Aluminum Al-05

[0022] 1.1 The sample is polished with 300# to 800# water sandpaper in turn, degreased with acetone, degreased with sodium hydroxide alkaline chemical, and lighted with nitric acid solution.

[0023] 1.2 Prepare a saturated lithium sulfate solution and adjust the pH value to 9.

[0024] 1.3 Put the saturated lithium sulfate into the constant temperature oil bath, turn on the switch of the constant temperature oil bath, and set the temperature of the oil bath to the working temperature of 90°C.

[0025] 1.4 When the temperature of the constant-temperature oil bath reaches 90°C, put the sample into a saturated lithium sulfate solution to form a Li-Al double hydroxy metal oxide reaction.

[0026] 1.5 After reacting for 1 hour, turn off the power to take out the sample, wash it with deionized water, and dry it with cold air.

[0027] 1.6 Adjust the temperature of the anodizing s...

Embodiment 2

[0030] Example 2 Preparation of Al-Li composite anodic oxide film on the surface of anti-rust aluminum LF12

[0031] 2.1 The sample is polished with 300# to 800# water sandpaper in turn, degreased with acetone, degreased with sodium hydroxide alkaline chemical, and lighted with nitric acid solution.

[0032] 2.2 Prepare a saturated lithium sulfate solution and adjust the pH value to 11.

[0033] 2.3 Put the saturated lithium sulfate into the constant temperature oil bath, turn on the switch of the constant temperature oil bath, and set the temperature of the oil bath to the working temperature of 95°C.

[0034] 2.4 When the temperature of the constant-temperature oil bath reaches 95°C, put the sample into a saturated lithium sulfate solution to carry out the reaction of forming Li-Al double hydroxyl metal oxide.

[0035] 2.5 After 2 hours of reaction, turn off the power to take out the sample, wash it with deionized water, and dry it with cold air.

[0036] 2.6 Adjust the te...

Embodiment 3

[0039] Example 3 Preparation of Al-Li composite anodized film on the surface of industrial pure aluminum L3

[0040] 3.1 The sample is polished with 300# to 800# water sandpaper in turn, degreased with acetone, degreased with sodium hydroxide alkaline chemical, and illuminated with nitric acid solution.

[0041]3.2 Prepare a saturated lithium sulfate solution and adjust the pH value to 12.

[0042] 3.3 Put the saturated lithium sulfate into the constant temperature oil bath, turn on the switch of the constant temperature oil bath, and set the temperature of the oil bath to the working temperature of 100°C.

[0043] 3.4 When the temperature of the constant-temperature oil bath reaches 100°C, put the sample into a saturated lithium sulfate solution to carry out the reaction of forming Li-Al double hydroxyl metal oxide.

[0044] 3.5 After reacting for 1 hour, turn off the power to take out the sample, wash it with deionized water, and dry it with cold air.

[0045] 3.6 Adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com