Process of producing ammonium nitrate with exhausted gas from synthetic ammonia freezing system

A refrigeration system and air release technology, applied in the direction of ammonium nitrate, refrigeration and liquefaction, liquefaction, etc., can solve the problems of increased ammonia water volume, increased energy consumption, and increased electricity load of ice machines, so as to reduce outlet pressure, The effect of increasing the air volume and reducing the power load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

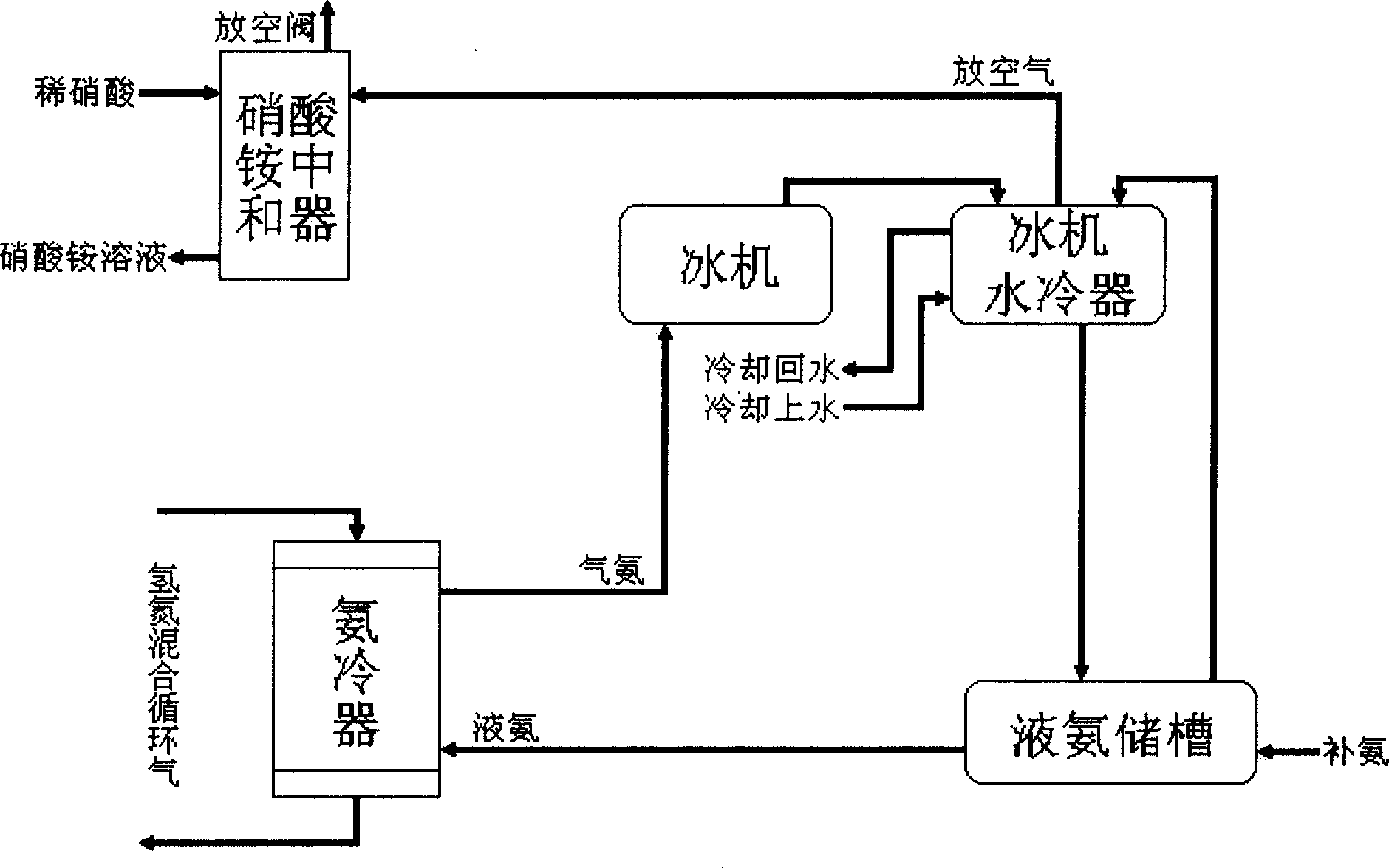

[0012] The liquid ammonia from the liquid ammonia storage tank is passed into the ammonia cooler of the synthetic ammonia section. After the hydrogen-nitrogen mixed circulating gas is cooled, the evaporated gas ammonia is all sent to the refrigeration system. After being pressurized by the ice machine, it is cooled in the ice machine water cooler It is liquid ammonia, which is sent into the liquid ammonia storage tank from the lower part for the recycling use of the ammonia cooler, and the insufficient part is supplemented by the large liquid ammonia storage tank.

[0013] The water cooler of the ice machine is connected with the gas phase of the liquid ammonia storage tank, and is used to vent the non-condensable gas accumulated in the water cooler of the ice machine. Release air directly into the ammonium nitrate neutralizer, react with nitric acid to produce ammonium nitrate solution, and form ammonium nitrate product through evaporation and crystallization process, in which...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap