Crushed coal pressure gasifying process for producing synthetic gas

A pressurized gasification of crushed coal and synthesis gas technology, applied in the direction of fixed bed gasification, combined combustion mitigation, etc., can solve the problems of inefficiency, complexity of synthesis gas, and ineffective utilization, so as to improve the level of energy saving and consumption reduction , Reduce gas dust removal load, improve the effect of coal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

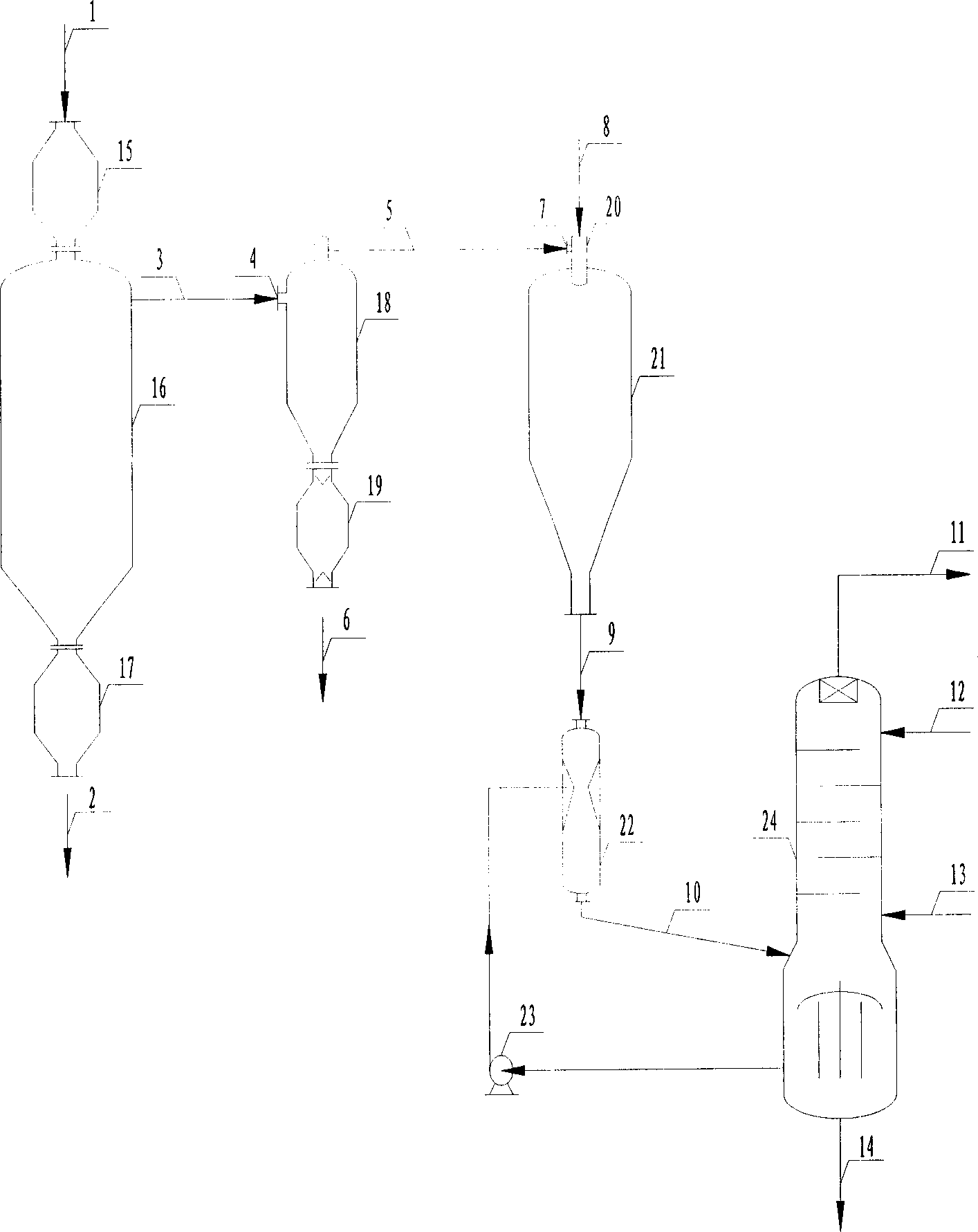

[0029] The method of the present invention can be implemented in the following devices.

[0030] The basic features of this device are: including a pressurized fixed-bed pulverized coal gasifier 16, a high-efficiency cyclone dust collector 18 with temperature resistance, pressure resistance and wear resistance, and a converter burner with at least one oxygen inlet. 20 converter 21 and a set of crude gas cooling and washing systems 22, 23, 24.

[0031] The features of the present invention will be understood in more detail according to the following description of the accompanying drawings:

[0032]The raw coal 1 enters the pressurized fixed-bed gasifier 16 through the coal lock 15, and the crude gas generated after reacting with the gasification agent is exported from the top outlet 3 of the gasifier; enters the cyclone dust collector 18 through the inlet 4 to remove dust, and then exits from the top 5 output; the preliminary dust-removed gas enters the converter burner 20 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com