Intelligent adjustable container overpressure protecting device and method based on magnetic flux variable liquid

An overpressure protection device and magnetorheological fluid technology, which are applied in container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve problems such as failure of explosion-proof device, high manufacturing cost, and inability to guarantee safe production. , to achieve the effect of simple device structure, easy manufacture and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

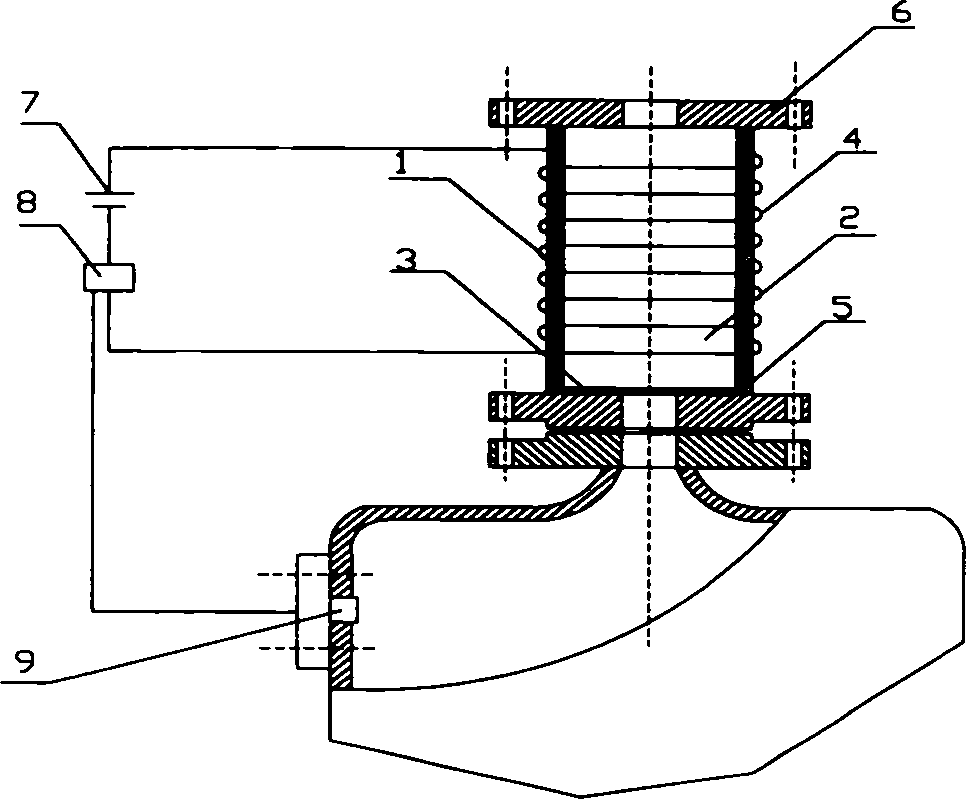

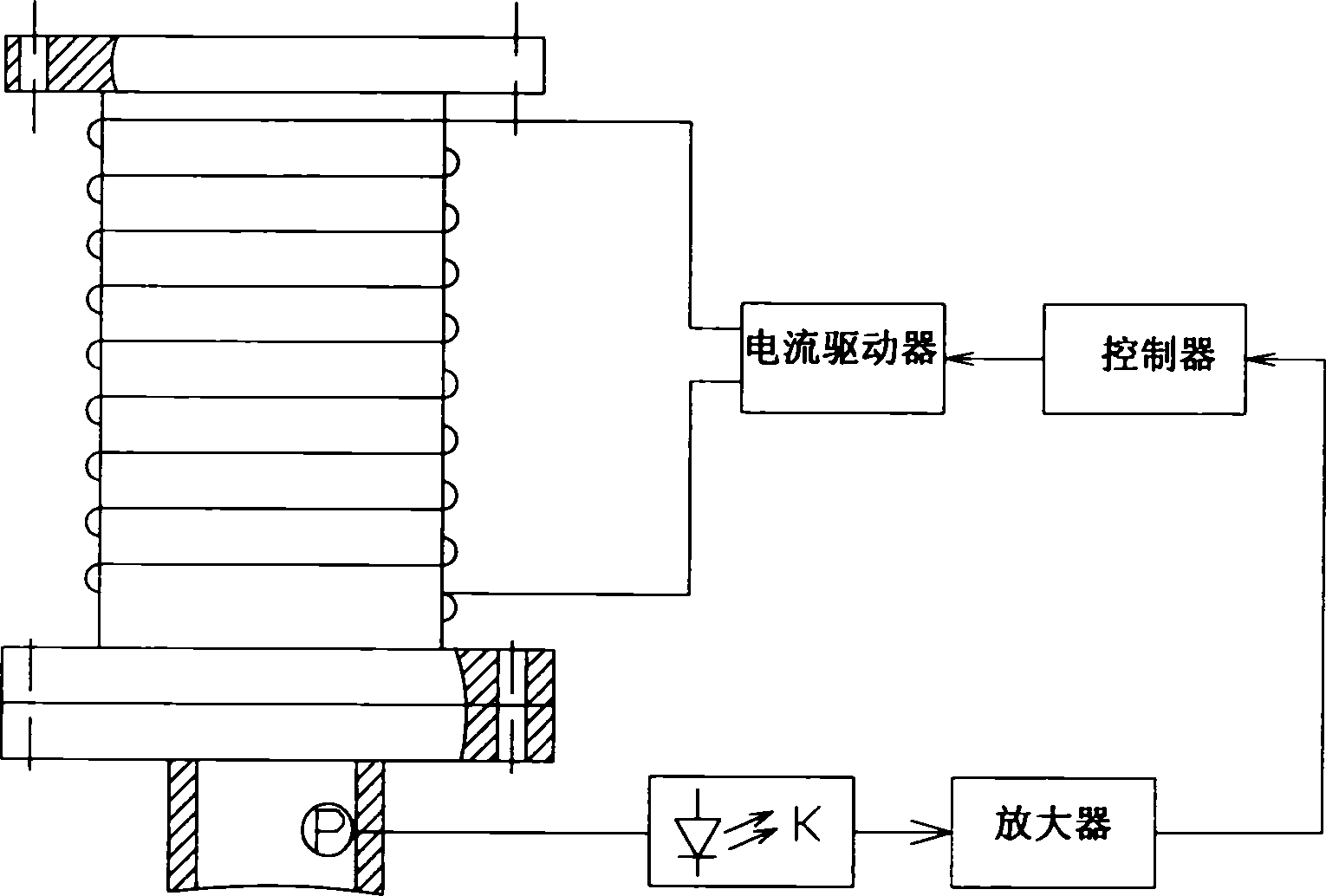

[0019] A sealed container with a volume of 5 liters has an explosion-proof interface, a vent valve, a pressure sensor interface, and a pressure gauge. The test setting pressure limit is 0.15 MPa. Installed on the explosion-proof interface of the container such as figure 1 The shown is an intelligent adjustable container overpressure protection device based on magnetorheological fluid, in which the diaphragm is a magnetorheological rubber gasket, and the upper and lower joints are flanges. figure 2 As shown, the pressure sensor 9 is installed in the container, the current driver 7 and the controller 8 are connected, and the current in the control program of the controller 8 is set to 30 volts and 1.5 amperes; when the test starts, the pressure gauge in the container shows the pressure It is zero, the pressure sensor 9 detects that the pressure in the container is lower than 0.15 MPa, the controller 8 provides power to the electromagnetic coil 4 through the current driver 7 acc...

Embodiment 2

[0021] A sealed container with a volume of 2 liters has an explosion-proof interface, a vent valve, a pressure sensor interface, and a pressure gauge, and the test setting pressure limit is 0.1 MPa. Installed on the explosion-proof interface of the container such as figure 1 The shown is an intelligent adjustable container overpressure protection device based on magnetorheological fluid, in which the diaphragm is an A3 steel gasket, and the upper and lower joints are screw ports. figure 2As shown, the pressure sensor 9 is installed in the container, the current driver 7 and the controller 8 are connected, and the current in the control program of the controller 8 is set to 20 volts and 1.0 ampere; when the test starts, the pressure gauge in the container shows the pressure It is zero, the pressure sensor 9 detects that the pressure in the container is lower than 0.1 MPa, the controller 8 provides power to the electromagnetic coil 4 through the current driver 7 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com