Method for measuring double-laser interferometer intersection angle non-orthogonality

A laser interferometer and non-orthogonal technology, applied in the field of lithography machines, can solve the problems of complex testing process, affecting the productivity of integrated circuit manufacturing, and taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention uses a special measurement system to measure the non-orthogonal value of the intersection angle of the laser beams of two laser interferometers by using a special mark arranged on a special mask in the special measurement system.

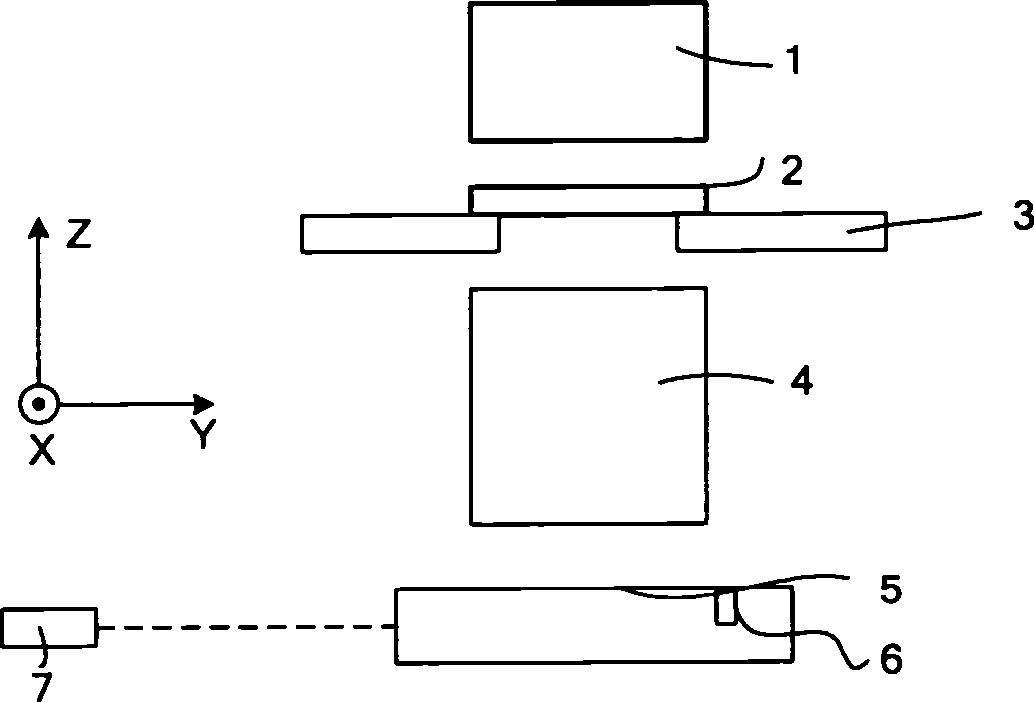

[0037] figure 1 As shown, it is a schematic diagram of the relative positional relationship between the mask and the measurement system of the present invention; the composition of the measurement system includes: an illumination system 1, a mask table 3 for placing a special mask 2, an optical system 4 for mask imaging, and a workpiece Stage 5, an image sensor 6, an X-direction laser interferometer 7, and a Y-direction laser interferometer 8 arranged on the workpiece stage 5.

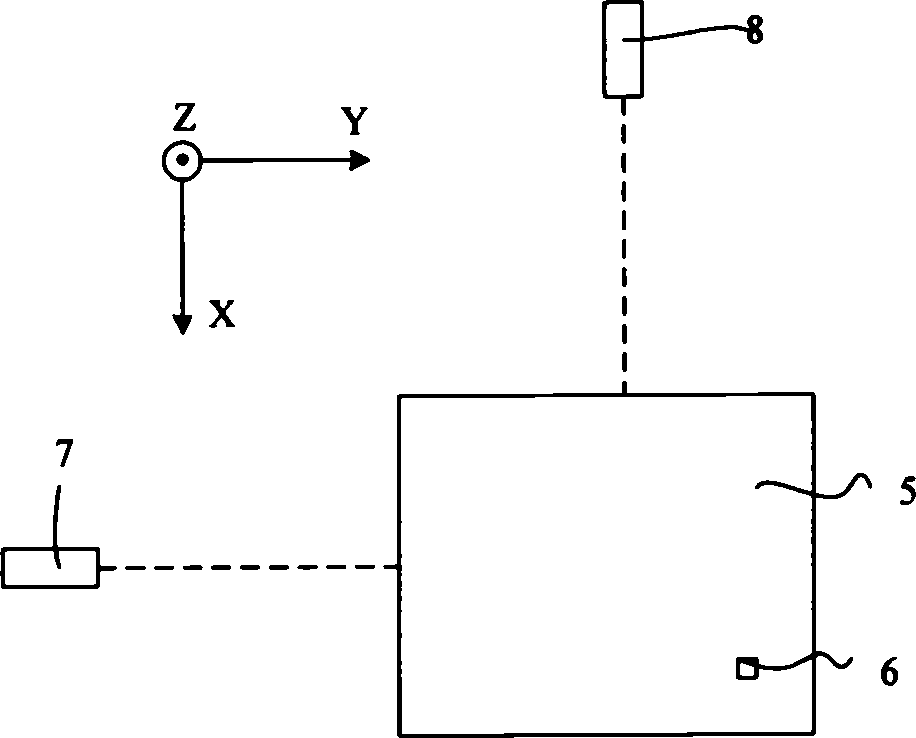

[0038] figure 2 As shown, the relative positional relationship between the laser interferometer 7 and the workpiece table 5 of the present invention has been shown. The laser beams sent by X and Y to the two laser interferometers 7 and 8 are reflected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com