Lead free solder friendly thermoplastic blends and methods of manufacture thereof

A plastic and warm technology, applied in the field of solder-resistant high-temperature thermoplastic compositions, can solve the problems of thermoplastic compositions no longer reliable, loss of insulation capacity, etc., and achieve the effect of improving thermal performance and improving high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

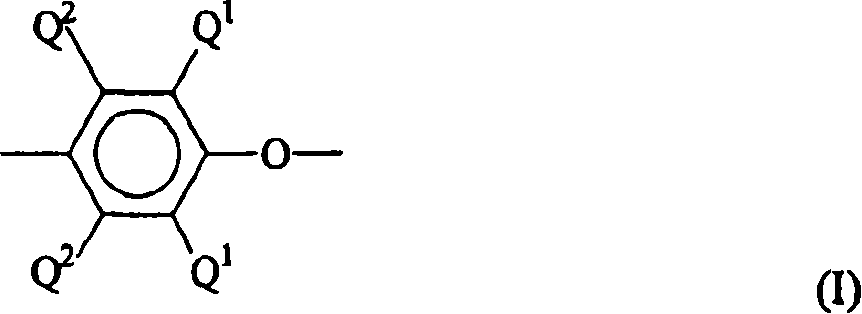

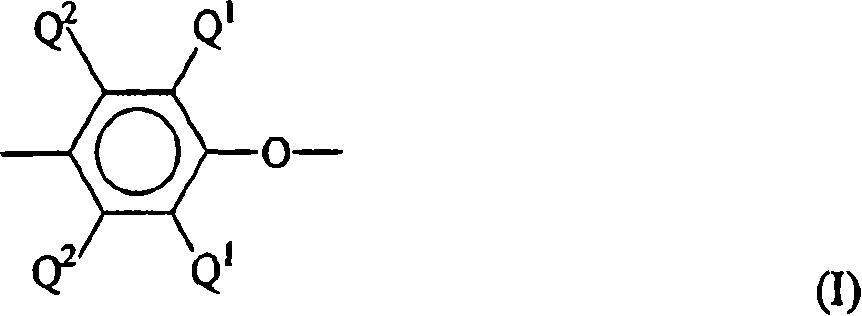

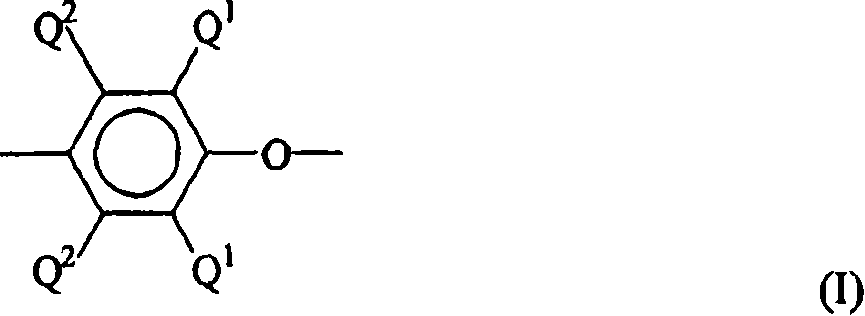

Method used

Image

Examples

Embodiment Construction

[0052] These examples illustrate the advantageous properties of high temperature thermoplastic compositions comprising poly(arylene ether) having an intrinsic viscosity of less than 0.15 dl / g. Sample 1 contained a low intrinsic viscosity polyphenylene ether (PPE) with an intrinsic viscosity of 0.12 dl / g; however, Sample 2 was a comparative example that contained a PPE with an intrinsic viscosity of 0.4 dl / g. Both PPE samples were manufactured by GE Plastics. The polyphenylene sulfide (PPS) is commercially available from Ticona Corporation as FORTRON 214 . This flow enhancer (lubricant) is available from Lonza Inc under the trade name GLYCOLUBE Pentaerythritol stearate (PETS) obtained. The glass fibers used were E-glass fibers obtained from Johns Manville. The glass fibers have a diameter of 13 microns and a length of approximately 3 mm. Table 1 below shows the respective detailed data of the components of Sample 1 and Sample 2.

[0053] The components of each lead-fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com