Nanometer-silver antibacterial coating, its preparation and use

A nano-silver antibacterial and nano-silver technology, applied in botany equipment and methods, applications, biocides, etc., to achieve the effect of killing or inhibiting pathogenic bacteria, accelerating healing, and promoting tissue repair and regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

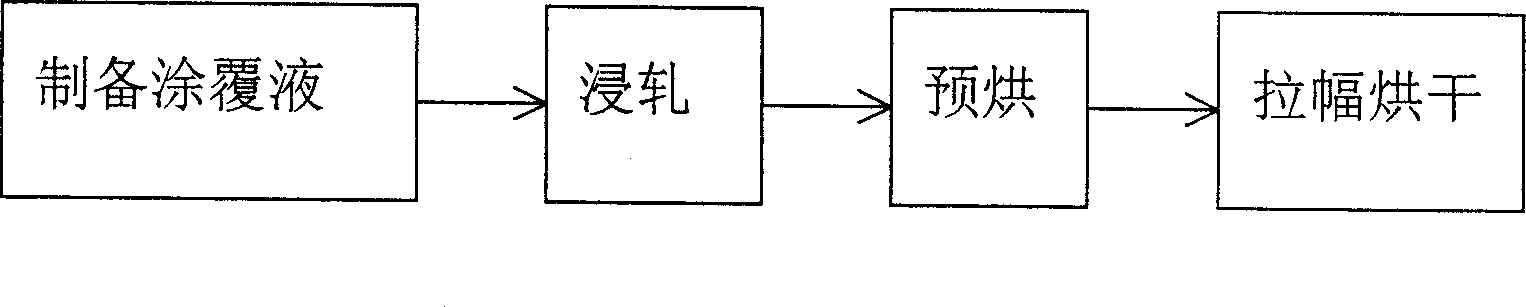

[0037] The preparation method of above-mentioned nano-silver antibacterial dressing, its technological process block diagram is as figure 1 shown, including the following steps:

[0038] a, preparation of coating solution: the nano-silver colloid stock solution can be the product of Korean patent PCT / KR2003 / 002855, the concentration of nano-silver can be 2000ppm or 10000ppm, a certain amount of medical adhesive, such as: polyvinyl alcohol (PVA ), the addition amount is 8-20% by weight, and it can also be methyl cellulose, the addition amount is 3-8%, and water: preferably pure water, and the above ingredients are mixed uniformly to make a coating liquid;

[0039] b. Padding: adding the coating solution into a padding tank, padding the substrate in the padding tank, and evenly coating the coating solution on the surface of the substrate layer;

[0040] c. Pre-baking: the substrate is pre-baked at 100-180 °C;

[0041] d. Stenter drying: The base material is dried at 100-150°C....

preparation example 1

[0049] a. Coating solution: add 1% AgNo 3 Dissolve in water, add 3% ascorbic acid for acidification, then add 20% ammonia water to generate ammonium nitrate, and generate a solution containing nano-silver particles. You can also add 15% polyvinyl alcohol as a binder to make a solution containing nano-silver particles coating solution; above percentages are percentages by weight;

[0050] b. Padding: the gauze is continuously passed through the padding tank filled with the above-mentioned coating solution, and then the gauze passes through a roller with a certain pressure, and the coating solution is evenly coated on the gauze;

[0051] c. Pre-drying: pre-dry the gauze continuously at 100-180°C;

[0052] d. Stenter drying: Continuously dry the gauze at 100-150°C;

[0053] Sample 1 was prepared by the above method, and the nano-silver content of sample 1 was 0.8% by weight.

preparation example 2

[0055] Other conditions are identical with preparation example 1, just a step is:

[0056]a, coating solution: 50kg of nano-silver colloid stock solution, the concentration of nano-silver is 2000ppm, the particle size distribution of nano-silver is 1-20 nanometers; polyvinyl alcohol (PVA), 15kg, and water: 30kg, the above raw materials well mixed;

[0057] Sample 2 was prepared by the above method, and the nano-silver content of sample 2 was 0.15% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com