Device for catalyzing and purifying indoor harmful gas

A harmful gas, catalytic purification technology, applied in the field of air purification devices, can solve the problem of incomplete removal of harmful substances, achieve the effect of large scope and improve air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of hot catalyst:

[0043] La(NO 3 ) 3 , 30%; Sr(NO 3 ) 2 20%; Mn(NO 3 ) 2 10% and Cu(NO 3 ) 2 40% was mixed and dissolved into an aqueous solution, and citric acid was added in a weight ratio of 1:2, and when ammonia water was added to adjust the pH to 9, activated alumina was soaked in the solution for 24 hours, and after the carrier was filtered out, slowly heated and dried, respectively After calcining at 300° C. and 700° C. for 4 hours, repeat the above three times to form a supported nanocomposite oxide catalyst.

[0044] Adopt the thermocatalyst that above-mentioned method obtains, its physicochemical parameter is as follows:

[0045] The specific surface area is 60~80m 2 / g.

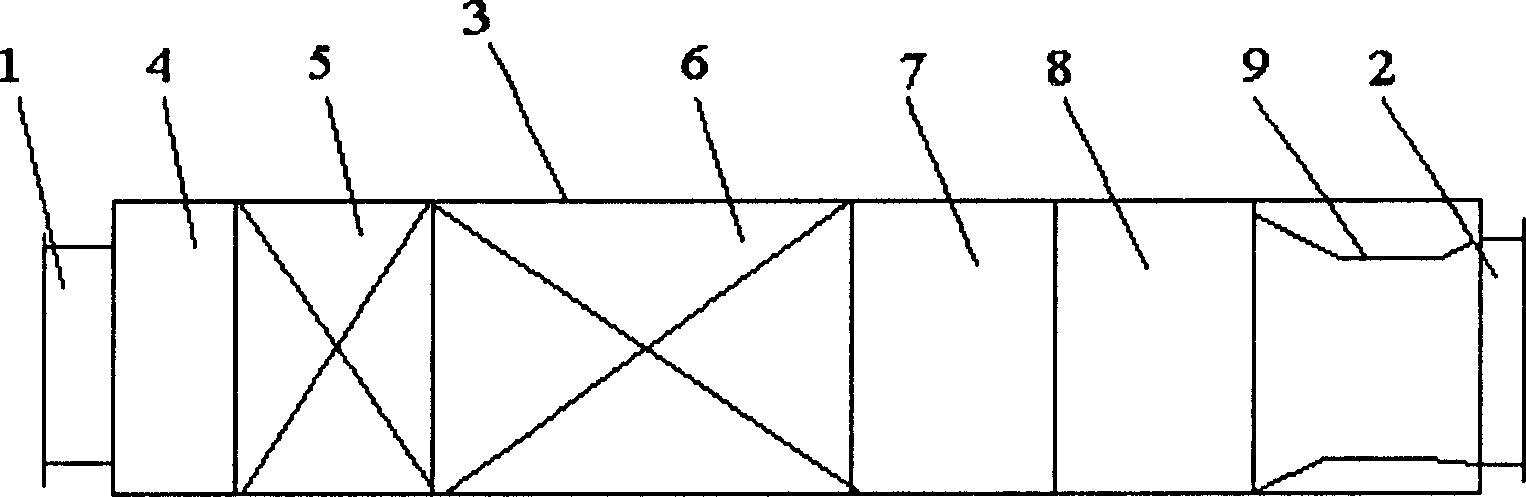

[0046] use figure 1 device shown.

[0047] Under the action of the said air-inducing device, the indoor harmful gas enters the device from the gas inlet, and passes through the filter to filter and remove the particles with a particle size greater than 0.3 μm;

[00...

Embodiment 2

[0059] Adopt the same device and method as embodiment 1, wherein:

[0060] La(NO 3 ) 3 , 30%; Sr(NO 3 ) 2 20%; Mn(NO 3 ) 2 20% and Cu(NO 3 ) 2 30% was mixed and dissolved into an aqueous solution, and citric acid was added in a weight ratio of 1:2. When ammonia water was added to adjust the pH to 9, activated alumina was soaked in the solution for 24 hours, and the carrier was filtered out and slowly heated and dried. After calcining at 300° C. and 700° C. for 4 hours, repeat the above three times to form a supported nanocomposite oxide catalyst.

[0061] Adopt the thermocatalyst that above-mentioned method obtains, its physicochemical parameter is as follows:

[0062] The specific surface area is 78m2 / g.

[0063] The air volume of indoor harmful gases in the device: 800 cubic meters per hour, the thermocatalytic temperature is 200 ℃, adopt the method stipulated in the national standard "Indoor Air Quality Standard" (GB / T18883-2002) of the People's Republic of China, ...

Embodiment 3

[0071] Adopt the same device and method as embodiment 1, wherein:

[0072] La(NO 3 ) 3 , 30%; Sr(NO 3 ) 2 20%; Mn(NO 3 ) 2 30% and Cu(NO 3 ) 2 20% was mixed and dissolved into an aqueous solution, and citric acid was added in a weight ratio of 1:2, and when ammonia water was added to adjust the pH to 9, activated alumina was soaked in the solution for 24 hours, the carrier was filtered out, and after slowly heating and drying, respectively After calcining at 300° C. and 700° C. for 4 hours, repeat the above three times to form a supported nanocomposite oxide catalyst.

[0073] Adopt the thermocatalyst that above-mentioned method obtains, its physicochemical parameter is as follows:

[0074] The specific surface area is 82m 2 / g.

[0075] The air volume of indoor harmful gases in the device: 1200 cubic meters per hour, and the thermocatalytic temperature is 220°C. The method stipulated in the national standard "Indoor Air Quality Standard" (GB / T18883-2002) of the Peop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com