Automatically on-line cleaning and water treatment for pipeline system

A pipeline system and automatic cleaning technology, applied in chemical instruments and methods, cleaning methods and utensils, magnetic field/electric field water/sewage treatment, etc. Good energy-saving effect, maintaining heat exchange efficiency, and remarkable effect of environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

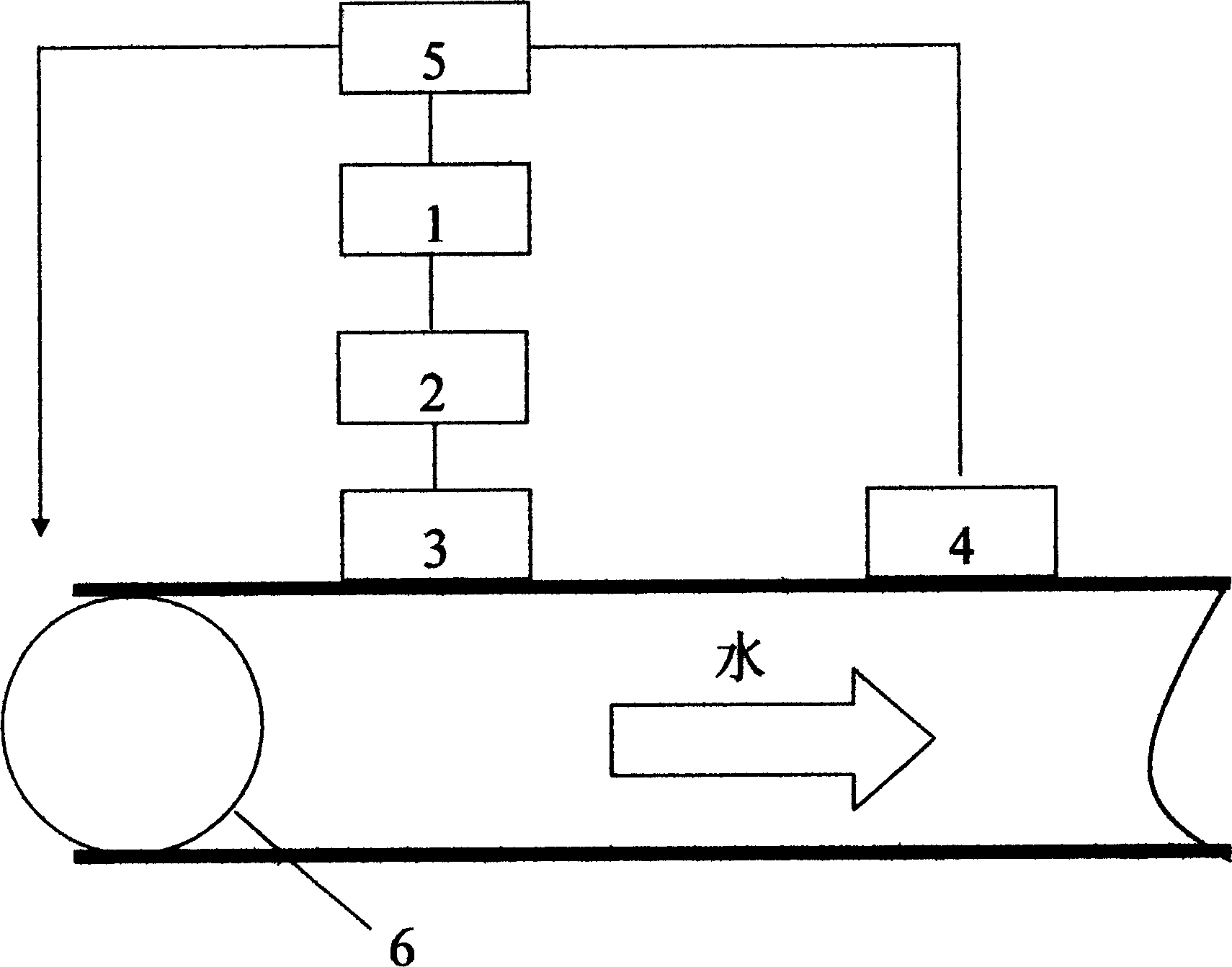

[0012] As shown in the figure, the system device of the present invention is composed of a PC 1 , a digital electromagnetic pulse generator 2 , an electromagnetic reactor 3 , a cleaning ball 6 , an injector 5 , and a ball returner 4 . PC 1 controls the operation of the whole device. Cleaning balls 6 are injected into the pipeline through the injector 5 at the inlet of the pipeline system, and the quantity of the balls is determined by the pipeline. The ball return device 4 recovers the cleaning ball 6 and sends it into the injector 5 to wait for the next cycle. The electromagnetic reactor 3 continuously induces the electromagnetic field generated by the digital electromagnetic pulse generator 2 to the pipeline system when the pipeline system is running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com