Interior photocatalytic coating, preparation method and application thereof

A photocatalytic and coating technology, applied in the field of indoor coatings, can solve the problems of dependence on chemical action, failure of sterilization performance, and limitation of practical application of composite technology, and achieve the effect of broadening the application range and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

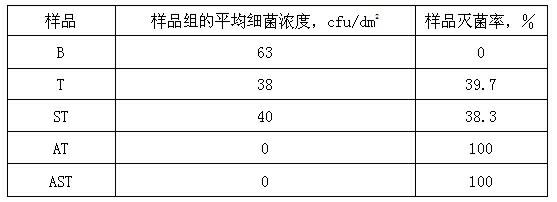

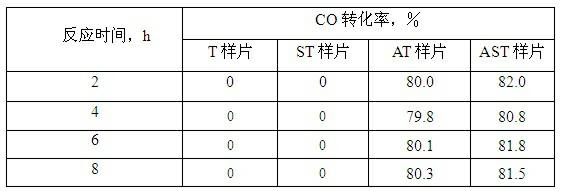

[0023] Embodiment 1: the preparation of pure titanium dioxide sol type photocatalytic coating

[0024] Add 1.1 ml of concentrated nitric acid (68%) into 150 ml of deionized water to make a uniform solution, slowly drop 12.5 ml of tetraisopropyl titanate into the acidic aqueous solution under vigorous stirring, and hydrolyze the suspension containing white precipitate The solution was continuously stirred at 40°C until the white precipitate dissolved to form a uniform and transparent sol. Put the sol into a dialysis membrane bag and use 2 liters of deionized water for dialysis treatment, and change the water every 12 hours until the final pH of the dialysis water is 3.2 to obtain a pure titanium dioxide sol with a titanium dioxide content of 2.5 wt%. This sol coating is denoted as T.

Embodiment 2

[0025] Embodiment 2: Preparation of silica / titanium dioxide composite sol-type photocatalytic coating

[0026] Under vigorous stirring, slowly drop 5 ml of ethyl orthosilicate into a solution made of 0.25 ml of concentrated nitric acid (68%) and 10 ml of deionized water, and continue stirring until a uniform and transparent silica sol is formed. After the sol passed through dialysis, 10 ml of it was mixed with 100 ml of the titanium dioxide sol prepared in Example 1, and then the same dialysis treatment as in Example 1 was carried out to adjust the pH value to 2.8. In this coating, the titanium dioxide content was 2.3 wt%, and the silica content was 1.1 wt%. This composite sol coating is marked as ST.

Embodiment 3

[0027] Embodiment 3: Preparation of pure titanium dioxide sol-type photocatalytic coating containing Au nanoparticles

[0028]0.7 mL HAuCl 4 (0.057 mol / L) was added to 20 mL of TiO prepared in Example 1 2 In the sol coating, stir evenly, then place in an ice-water bath, add 1 drop of concentrated nitric acid to acidify (maintain pH = 2), add NaBH drop by drop under strong stirring 4 solution (0.05 g NaBH 4 Dissolved in 20 mL deionized water), fully reacted, the sol changed from white to purple, and a titanium dioxide sol-type coating containing nano-Au particles was prepared, wherein the Au content was 0.02g / 100mL. This paint is recorded as AT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com