Ageing processing method for pu'er tea

A processing method and technology for Pu-erh tea, applied in the field of tea processing, can solve problems such as unfavorable yield, carbonization of piling center tea, impact on yield and quality, etc., and achieve the effects of easy operation and control, elimination of carbonization of tea leaves, and stable production indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

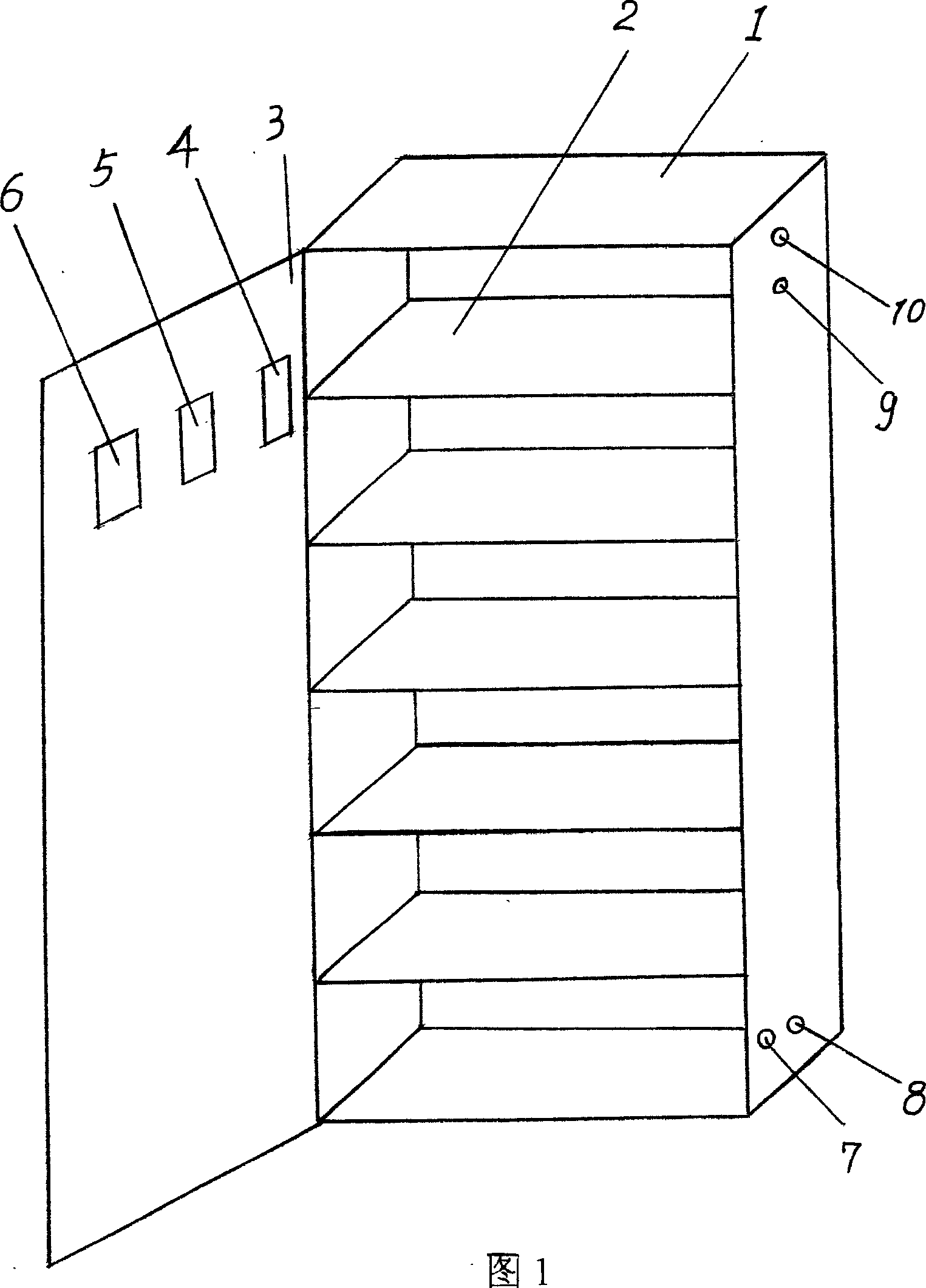

Image

Examples

Embodiment 1

[0021] A. Put the sun-dried green tea into a closed container with a vacuum degree of 280mmHg, and heat it with steam to regain moisture for 3 minutes to obtain moisture-resurgent tea leaves with a water content of 18%;

[0022] B. Get the strains according to the following mass ratios:

[0023] Aspergillus niger 40%

[0024] Penicillium 20%

[0025] Rhizopus 10%

[0026] Yeast 30%

[0027] After mixing the above strains, according to the mass ratio of strains: water = 1: 100, the strains are dissolved in water to obtain bacteria-containing water;

[0028] D, by tealeaves: the mass ratio of water=100:20, the bacterium-containing water of B step is mixed with the regain moisture tealeaves of A step, and the total water content of control tealeaves is 35%;

[0029] E. Place the tea leaves in step D in layers in a closed container, feed oxygen at a temperature of 40° C., control the oxygen content to 80%, and ferment for 4 days;

[0030] F, repeat step E 3 times, after sievi...

Embodiment 2

[0032] A. Put the sun-dried green tea into a closed container with a vacuum degree of 350mmHg, and heat it with steam to regain moisture for 1 minute to obtain moisture-resurgent tea leaves with a water content of 25%;

[0033] B. Get the strains according to the following mass ratios:

[0034] Aspergillus niger 60%

[0035] Penicillium 15%

[0036] Rhizopus 10%

[0037] Yeast 15%

[0038] After mixing the above strains, according to the mass ratio of strains: water = 3: 100, dissolve the strains in water to obtain bacteria-containing water;

[0039] D, by tealeaves: the mass ratio of water=100:5, the bacterium-containing water of B step is mixed with the regain moisture tealeaves of A step, and the total moisture content of control tealeaves is 28%;

[0040] E, the tea leaves of step D are layered and placed in a closed container, and oxygen is introduced at a temperature of 65°C, and after the oxygen content is controlled to 80%, ferment for 5 days;

[0041] F, repeat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com