Process for producing light aggregate concrete plate

A technology of lightweight aggregate concrete and manufacturing process, which is applied in the direction of manufacturing tools, layered products of hydraulic materials, lamination, etc., can solve the problems of polluting the air environment, destroying soil resources, and large energy, so as to achieve no energy consumption, Accelerated foundation subsidence, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

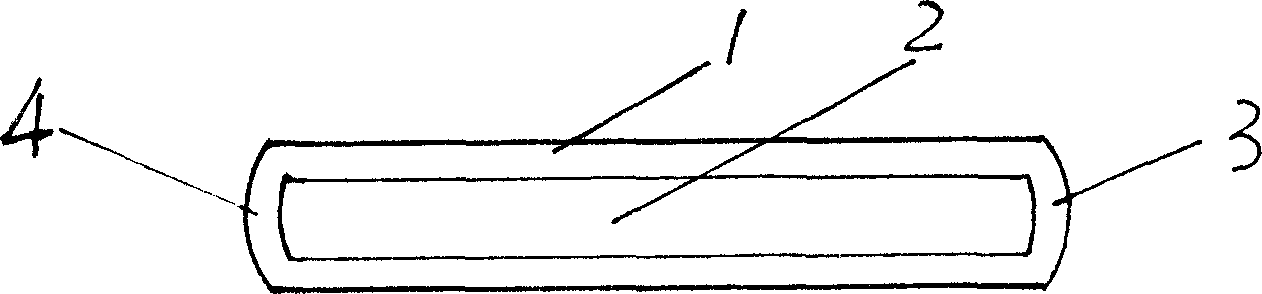

[0013] Such as figure 1 Shown, the product of the present invention is made up of foamed light aggregate concrete strip 1, is provided with one deck polystyrene foam interlayer 2 in the foamed light aggregate concrete strip 1, and described foam At least two of the four sides of the lightweight aggregate concrete slab 1 are curved sides 3,4.

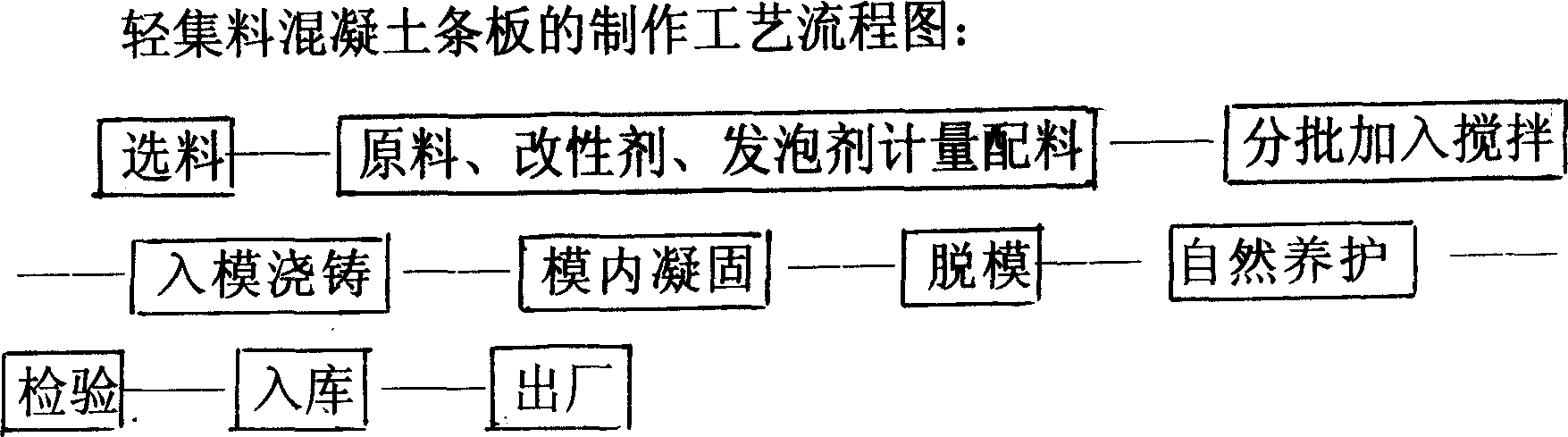

[0014] Such as figure 2 As shown, the production process of the present invention is: material selection - raw material, modifier, foaming agent metering and proportioning - adding and stirring in batches - casting in the mold - solidification in the mold - demoulding - natural curing ——inspection——warehousing——delivery.

[0015] 1. Material selection:

[0016] The present invention mainly selects plant fiber as the main raw material, (plant fiber can make full use of crop orange stalks, rice husks, sawdust, bamboo chips, etc.), industrial "three wastes" fly ash as filler, magnesium oxychloride cement as cementitious material, Use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com