Preparing nano particle/thermoplastic polymer composite material by flexible method

A nanoparticle and composite material technology, which is applied in the field of preparing nanoparticle/thermoplastic polymer composite materials, can solve the problem that nanoparticles are difficult to form nanoscale dispersion, and achieve the effect of low equipment requirements, easy popularization and application, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

[0043] (1) Dissolve the dispersant in water at 1-95°C and make it transparent for later use. The nanoparticles are placed in a beaker, a certain amount of distilled water is added, and the obtained solution is dispersed in an ultrasonic wave for 1-100 minutes to prepare a nanoparticle pre-solution. Add the nanoparticle pre-solution into the dispersant solution, and stir continuously for 1-100 min.

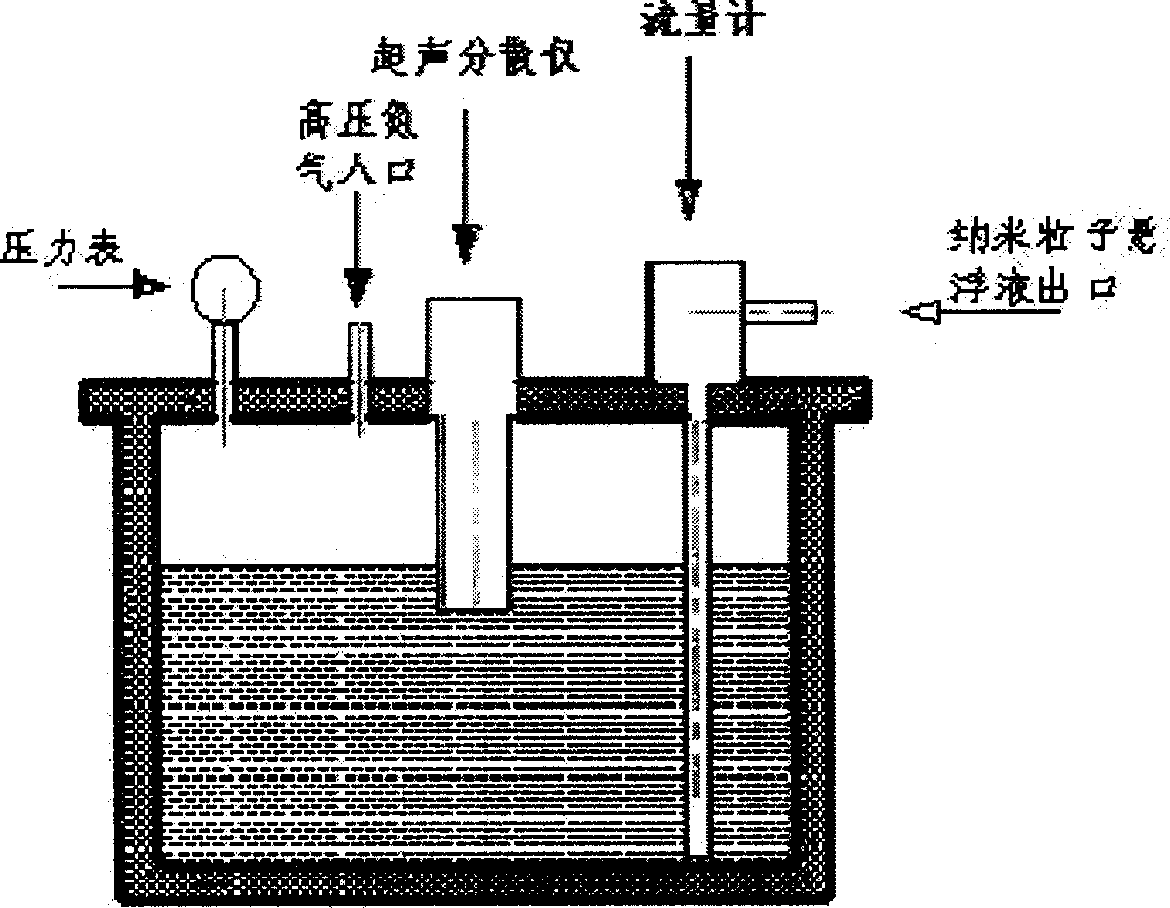

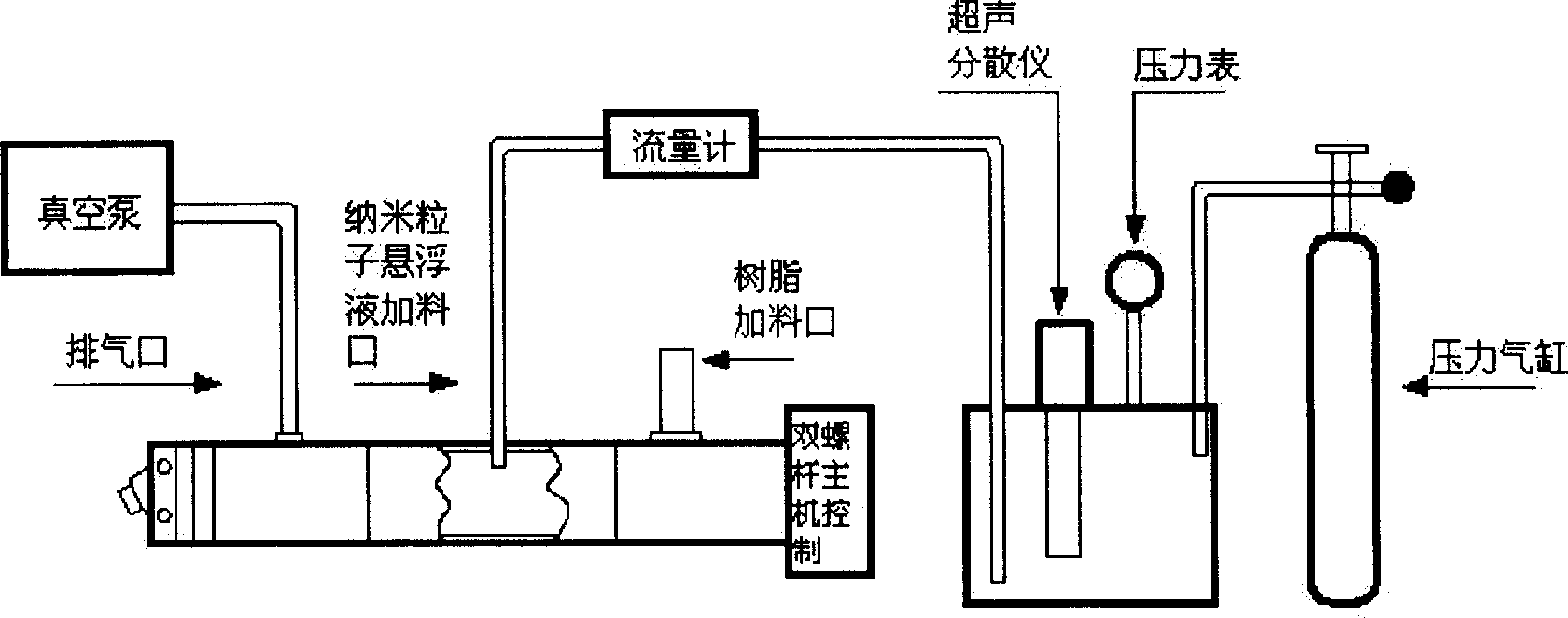

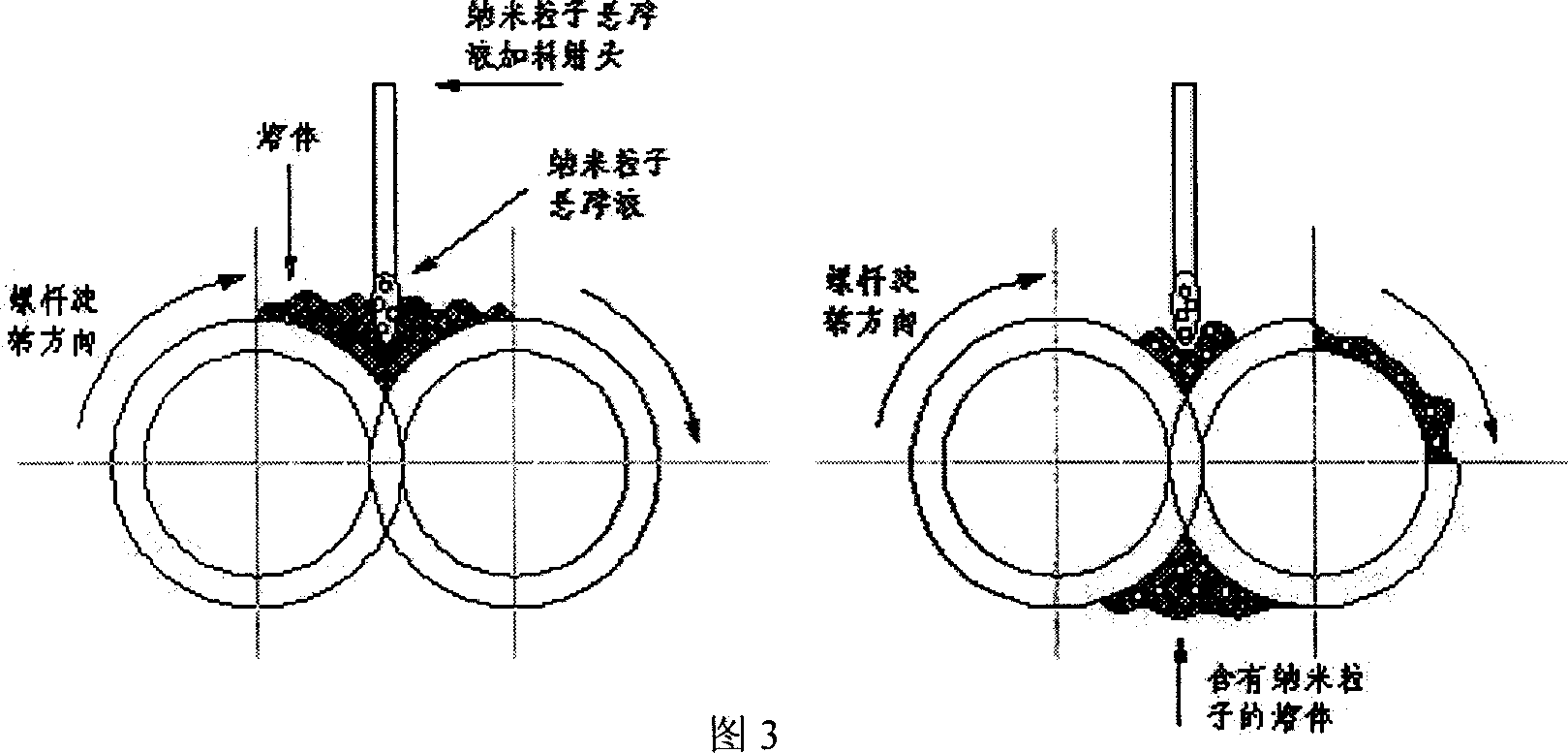

[0044] (2) Add the stirred and dispersed solution into a self-developed pressure-type continuous dispersion secondary feeding device for continuous ultrasonic dispersion to obtain a uniform dispersed suspension for use. .

[0045] (3) Connect the secondary feeding device with the twin-screw extruder, and feed a certain pressure of inert gas into the secondary feeding device.

[0046] (4) Add the thermoplastic polymer into the hopper of the twin-screw extruder, adjust the screw speed to 10-600rpm, the feeding speed to 5-200rpm, and start the machine. The internal pressure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com