SMC sheets and its prepn. method

A sheet and core material technology, applied in the field of SMC sheet and its preparation, can solve the problems of poor product surface quality, poor flow performance, large post-repairing workload, etc., achieve good gloss, improve production efficiency, reduce curing Effects of time and molding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The third step: the preparation method of the SMC sheet, comprising the following steps:

[0046] 1) According to the order of unsaturated polyester resin, low shrinkage additive, internal mold release agent and calcium carbonate, add in sequence in proportion, after mixing evenly, add styrene, initiator and magnesium oxide, mix and stir evenly to make resin paste; According to the special requirements of the process, color paste and / or additives can also be added in proportion to the resin paste;

[0047] Component A composed of unsaturated polyester resin, low-shrinkage additive, internal mold release agent, calcium carbonate, etc. requires sufficient stirring time so that each component can be mixed evenly to avoid product defects. Component B composed of styrene, initiator and magnesium oxide should be added before production, and the amount added should be accurate. At the same time, it is required to ensure sufficient stirring time, but the stirring time should not ...

Embodiment 1

[0052] Embodiment 1: SMC sheets of different low-shrinkage additives

[0053] Low-shrinkage additives are the most important factor in determining the surface quality of products, and are also the main determinant of the cost of SMC sheets. Depending on the application in different auto parts, the required shrinkage rate is different, and the selection of different low-shrinkage additives will have different effects on SMC sheets.

[0054] Step 1: Prepare the resin paste

[0055] Resin paste composition (parts by weight):

[0056] Composition of component A:

[0057] Ortho-phthalic resin: 60 parts

[0058] PVAc: 40 parts

[0059] Zinc stearate: 3.5 parts

[0060] BYKW-972: 1 part

[0061] 325 mesh calcium carbonate: 80 parts

[0062] 600 mesh calcium carbonate: 40 parts

[0063] Composition of component B:

[0064] Styrene: 5 parts

[0065] TBPB: 1 serving

[0066] Magnesium oxide: 1.4 parts

[0067] Titanium white paste: 1 part

[0068] When preparing the resin p...

Embodiment 2

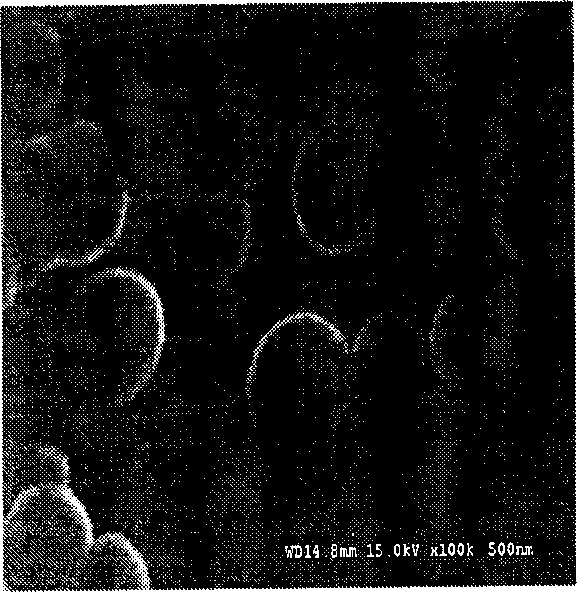

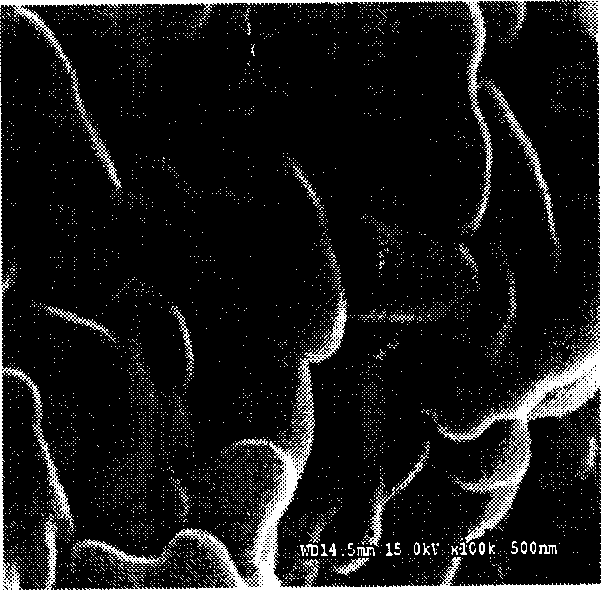

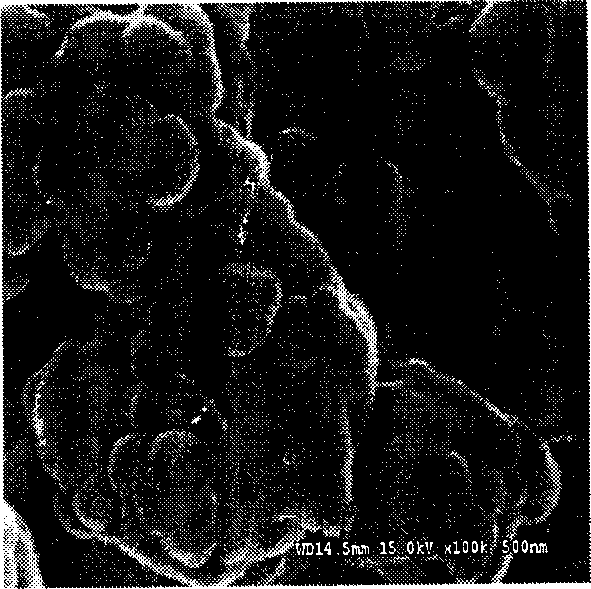

[0077] Embodiment 2: the influence of filler on SMC sheet

[0078] In the SMC process, the filler system plays an increasingly important role in improving the performance of the resin system and the final performance of the product. The main function of the filler is to reduce the cost of materials, improve the manufacturability of SMC manufacturing and molding, and improve various related properties of SMC products, such as surface properties, electrical properties, flame retardant properties, mechanical properties, etc. Under the condition of high filler content, the smaller the particle size of the filler, the smaller the apparent viscosity of the SMC resin paste and the higher the surface quality. Therefore, to maximize the benefits of fillers in SMC, careful consideration must be given to the type, amount and grade of material. In the present invention, calcium carbonate is adopted as a filler, and suitable fillers and consumption are selected by affecting the particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com