Surface material for display and display with the same

A technology for surface materials and displays, which is applied to devices for coating liquid on the surface, electronic equipment, special surfaces, etc. It can solve the problems that the coating is not suitable for actual use and cannot meet the visibility of the display surface, etc., and achieve excellent visual Sexuality, inhibition of fingerprints, and effects of avoiding liquid droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Aluminum sec-butoxide [Al(O-sec-Bu) 3 ], isopropanol [IPA] and ethyl acetoacetate [EAcAc] were mixed and stirred. Further, add the mixed solution of water and Virahol, the molar ratio of said substance is as follows: Al(O-sec-Bu) 3 :IPA:EAcAc:H 2 O=1:10:1:4, stirred at room temperature for about 1 hour to prepare alumina sol.

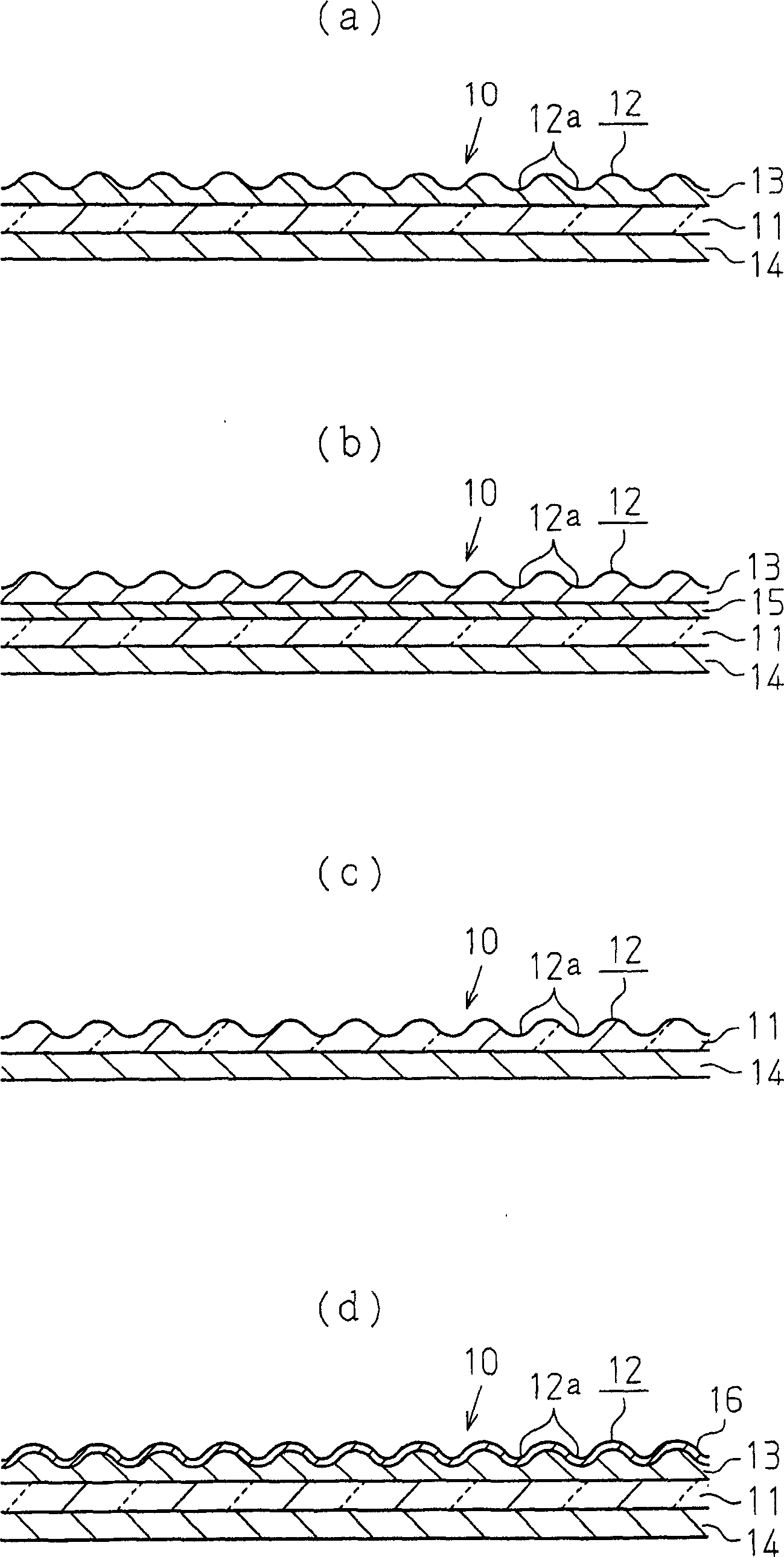

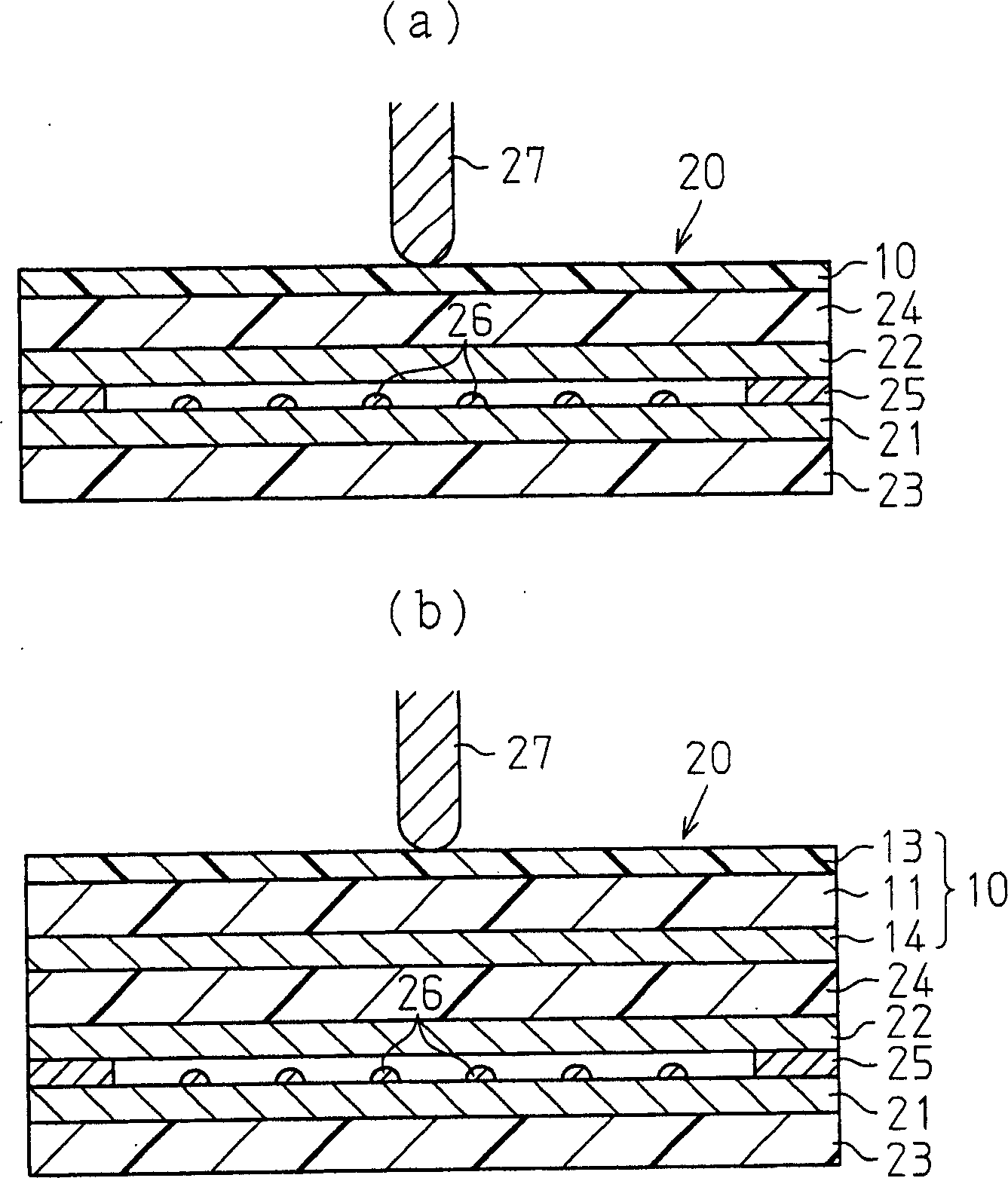

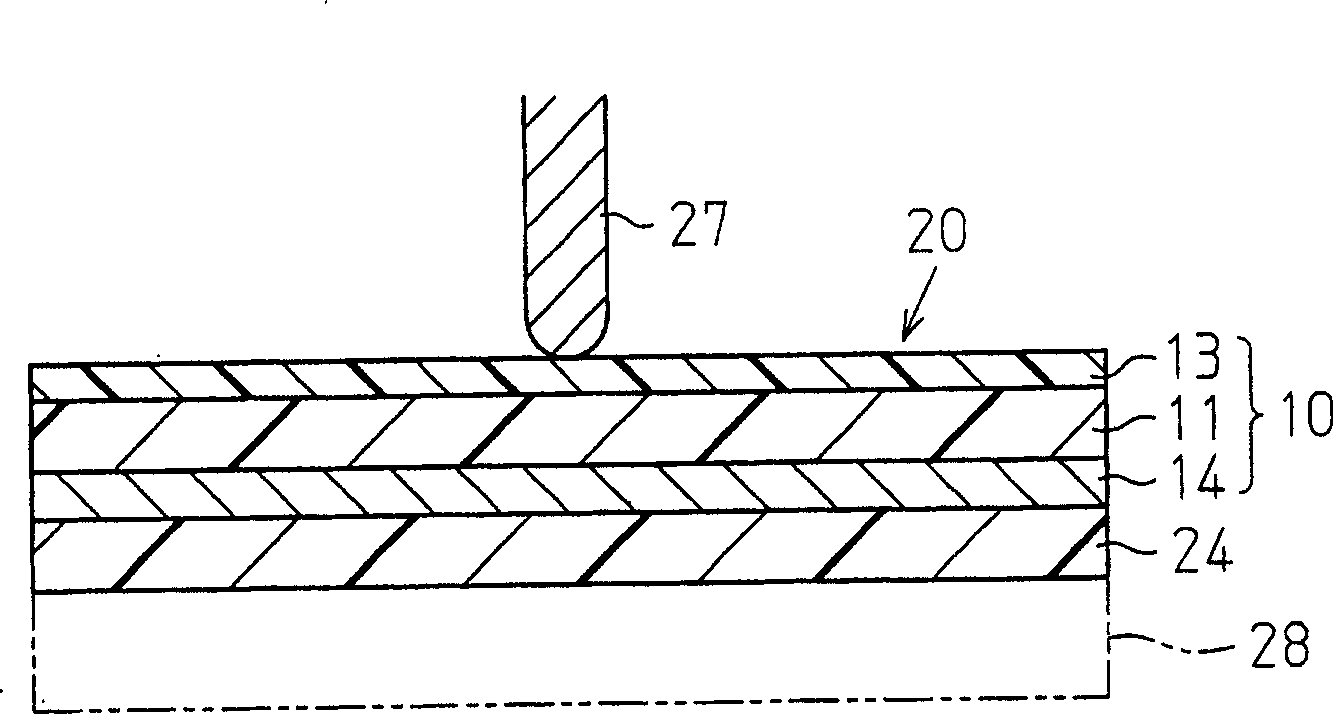

[0092] Use the obtained alumina sol solution to dip-coat, further dry, and use a polyethylene terephthalate (PET) substrate with a thickness of 100 μm as the transparent substrate 11, on which to fabricate Aluminum oxide layer. Next, the aluminum oxide layer was immersed in warm water adjusted to have an electrical conductivity of 1.5 μs / cm at 60° C. for 1 hour, and then dried in an oven at 150° C. to obtain the uneven layer 13 . The thickness of the concavo-convex layer 13 is 200 nm.

[0093] The arithmetic average roughness (Ra) and the average interval (Sm) between the concavities and convexities of the surface of the concavo-convex layer...

Embodiment 2

[0095] As the transparent base material 11, except having used a glass substrate instead of a PET film, film formation was performed by the same operation as Example 1, the surface material 10 for displays was manufactured, and the touch panel 20 was further manufactured. The thickness, Ra, and Sm of the formed concavo-convex layer 13 were 210 nm, 38 nm, and 340 nm, respectively. In addition, for the surface material 10 for a display, the fingerprint visual evaluation and the measurement of the total light transmittance and the haze value were performed, and these results are shown in Table 1.

Embodiment 3

[0096] (Example 3: Forming a hard coating layer as a functional layer 15 between the transparent substrate 11 and the uneven layer 13)

[0097] As a hardening coating solution, it is prepared as follows: 70 parts by mass of dipentaerythritol hexaacrylate, 20 parts by mass of tetramethylolmethane triacrylate, 10 parts by mass of 1,6-bis(3-acryloyloxy 2-hydroxypropyloxy)hexane, 4 parts by mass of a photopolymerization initiator (trade name: IRGACURE184, manufactured by Chiba Gaigi Co., Ltd.), and 100 parts by mass of isopropanol were mixed to prepare the mixture. Hard coating fluid. This hard coat solution was applied on a PET film with a thickness of 100 μm by a bar coater so that the thickness of the dried film was about 4 μm, and irradiated with 400 mJ by a 120 W high-pressure mercury lamp using an ultraviolet irradiation device (manufactured by Iwasaki Electric Co., Ltd.) UV rays are used to cure and produce hard-coated PET films. Except having used this hard-coated PET fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean roughness | aaaaa | aaaaa |

| Mean interval | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com