Three terminal type magnetic flow gate sensor

A fluxgate sensor and sensor technology, which is applied to the magnetic field measurement and the size/direction of the magnetic field using the principle of magnetic flux control, and can solve the problems of inconvenient winding of the measuring coil, poor noise, and large excitation power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

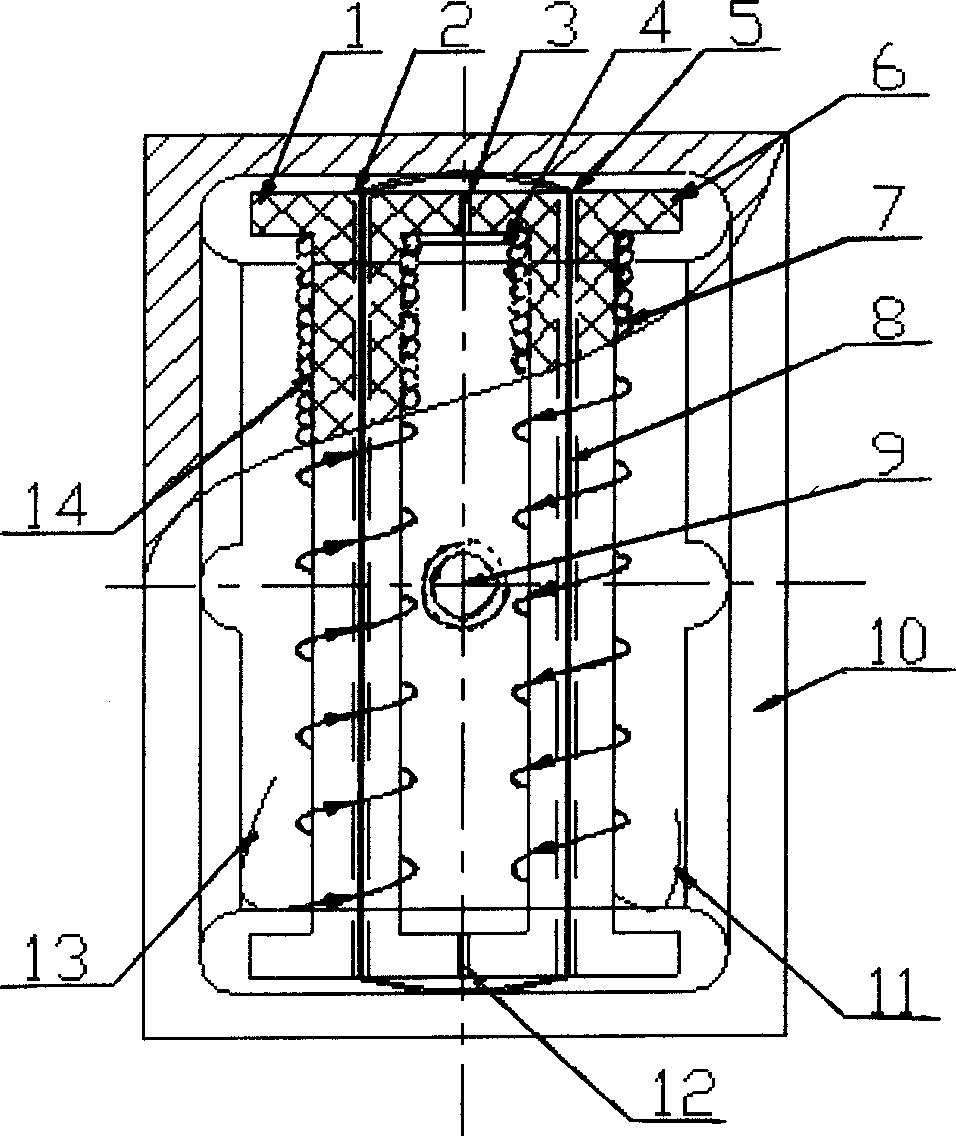

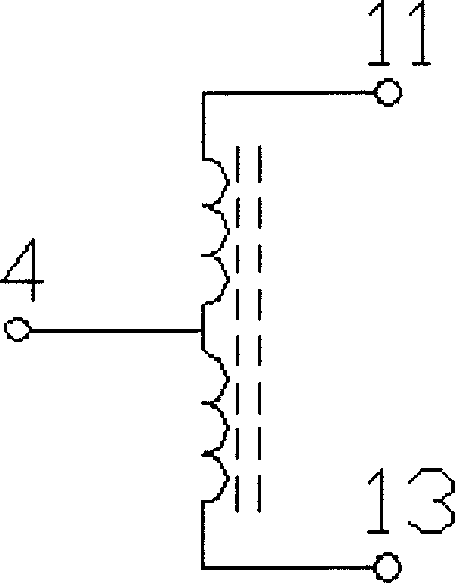

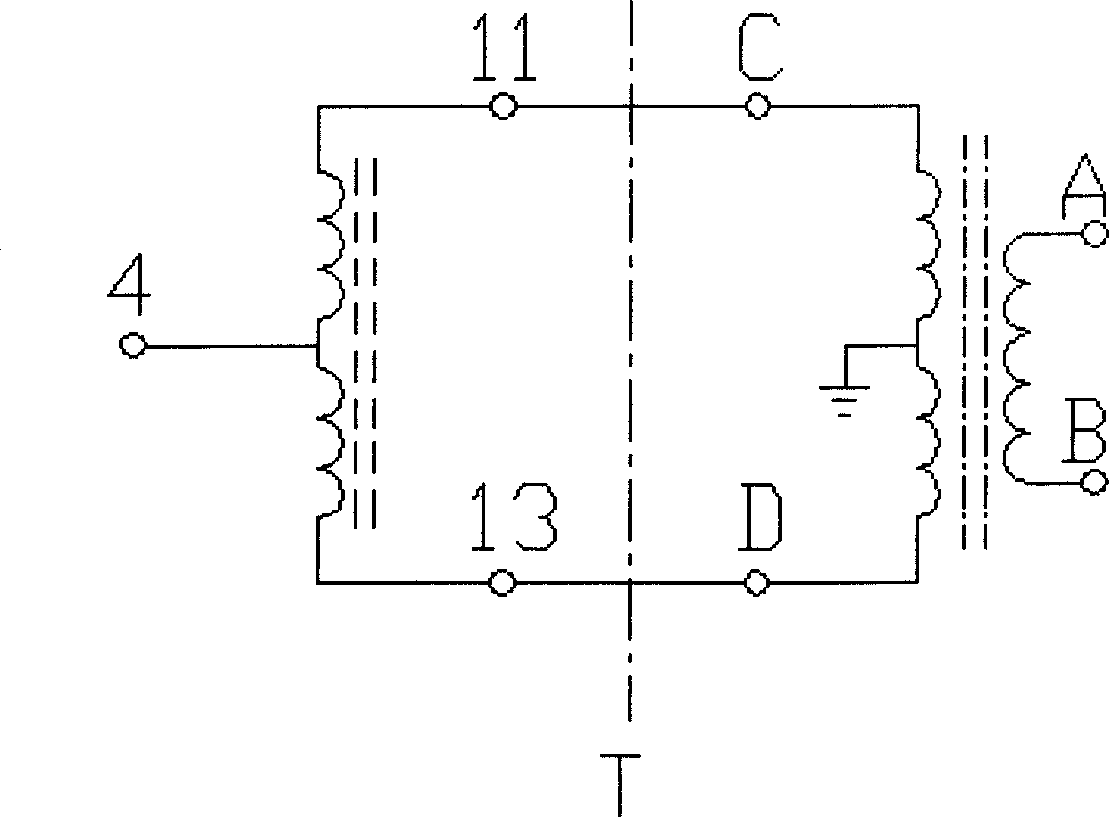

[0017] see figure 1 , 1 and 6 are "I"-shaped ceramic skeletons, 14 and 7 are two sets of coils tightly and evenly wound on the skeletons 1 and 6, and 800 to 1000 turns are wound with φ0.1 enameled wire, and the winding direction of the coils is as shown by the arrow. 13 is the starting end of the coil 14, and 11 is the end of the coil 7. The end of the coil 14 and the beginning of the coil 7 are connected to form the central end 4. 3 and 12 are the two joints of the "I"-shaped ceramic skeleton 1 and 6, forming a coil assembly of the "II"-shaped skeleton. 2 and 5 are the center holes of the "I"-shaped ceramic skeletons 1 and 6 respectively, and 1J86 permalloy strips are stacked and wound in the center holes 2 and 5 in series for 2 to 4 turns to make a racetrack-shaped magnetic core 8. 10 is no The magnetic aluminum box is used to place the "II" shaped magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com